26

ELECTRIC INSTALLATION

F306

FUSE BOX

Accessible after removing the left cover

of the steering bracket.

Blade fuses (1) are used; replace with

fuses of the same value only. If a fuse

breaks repeatedly, consult the nearest

service station.

Tape glow fuse (2) with the value of 80A.

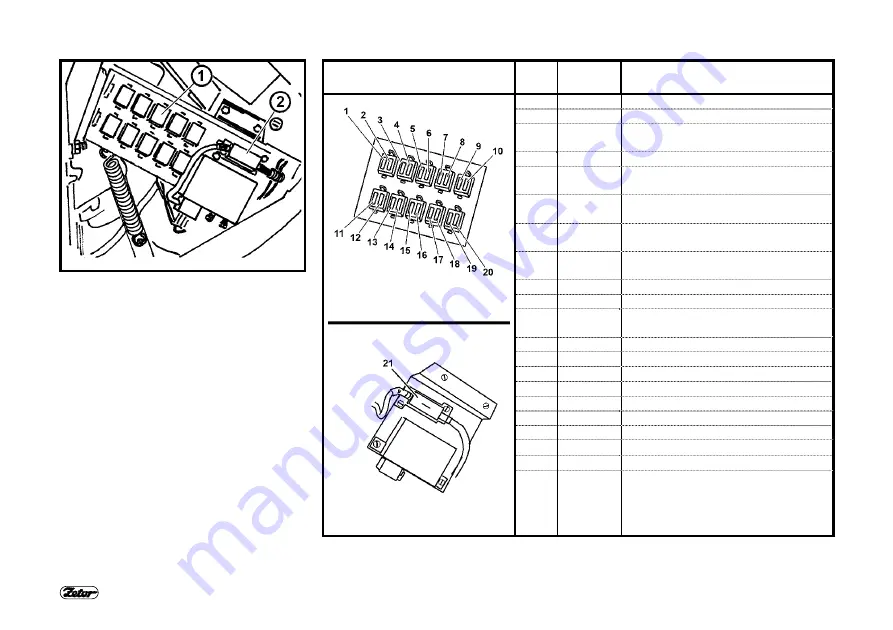

Location of fuses in fuse box Posi-

tion

Fuse

value

System to which it applies

1

15A

warning lights chopper, breaking lamps

2

15A

horn, warning beacon

3

15A

front drive axle control, differential

lock control, dashboard power supply

4

15A

high beam headlamps and indicator

5

15A

side lamps, dashboard lamps, license

plate lamps

6

15A

right side lamps, rear working lamp

and indicator

7

15A

right low beam headlamps, fog lamps

and indicator

8

7,5A

left headlamp, bonnet mask / roof

lamps, indicator

9

15A

working lamps in the bonnet mask

*10

3A

Zuidberg front shaft

11

15A

windscreen and rear window wipers,

washers, radio “15“

12

20A

heater fan, radio “30“

13 15A

recirculation,

lighter

∗

14

7,5A air-conditioning

(compressor clutch)

*15 15A

mirror

heating

*16

15A

rear window defroster

*17

15A

driver’s seat compressor

18

20A

3-pole socket

∗

19

15A

front working lamps on the roof

∗

20

15A

rear working lamps on the roof

D307

21 80A

glowing