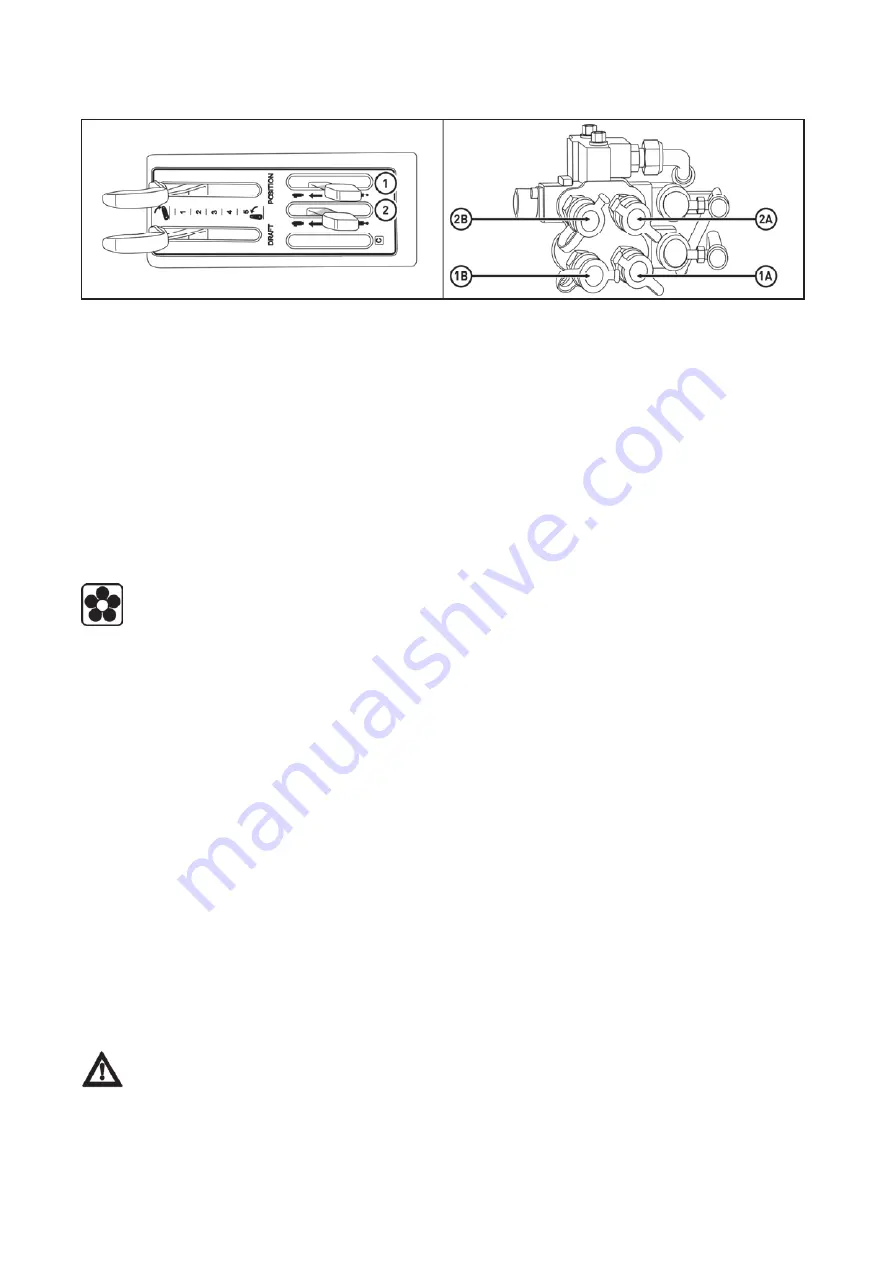

Outer hydraulic circuit controls

UCL18NN029

By moving the lever (1) forward, pressure oil is supplied to the quick coupler (1A).

By moving the lever (1) backwards, pressure oil is supplied to the quick coupler (1B).

By moving the lever (2) forward, pressure oil is supplied to the quick coupler (2A).

By moving the lever (2) backwards, pressure oil is supplied to the quick coupler (2B).

The SCVs quick couplers are operated by levers (1) and (2) located on the panel on the right side of the

driver's seat.

Important:

As soon as the implement operated by the pressure oil from the quick couplers reaches the end of the

stroke, return the lever to the middle (neutral) position, when there is no oil pressure in the quick couplers;

otherwise the oil will flow through the relief valve. When the oil is pushed through the relief valve for a longer

period of time, oil becomes overheated. When using the tractor hydraulic system to drive the front loader, do

not use the SCVs and the loader at the same time.

Remote hydraulic control valve coupler connecting and disconnecting

When connecting and disconnecting the quick-couplers pay increased attention with regard to

the residual oil that remains in the socket or on the plug of the quick-coupler. For environmental

reasons after every disconnection of quick-couplers this residual oil must be removed with any

textile material.

Connection

1) Do not forget to stop the engine before connecting the implement.

2) Move the lever of the double-acting valve forward and backward 4 to 5 times to release the pressure in the

tractor's hydraulic lines. Otherwise it may be difficult to attach the couplers and hydraulic fluid may splash out

of the hoses and strike the eyes when coupling.

3) Remove any dirt around the couplers. If dirt enters the hydraulic parts, the system may fail.

4) Open the dustproof clutch cover on the tractor and connect the implement coupler. You should hear

a click when the coupler is engaged.

5) Pull the hydraulic hose to check that the couplers are correctly connected.

6) Start the engine and check for operation and leaks.

Disconnection

1) Do not forget to stop the engine before disconnecting the implement.

2) Relieve the residual pressure in the hydraulic hoses of the machine and the tractor by moving the lever of

the double-acting valve 4 to 5 times backwards and forwards.

3) Remove any dirt around the quick couplers.

4) Keep the implement unloaded by removing all load (e.g. by lowering or placing the implement on the mat).

If the hose is disconnected when the implement is loaded, it will be difficult to reconnect it in the future.

5) Disconnect the quick couplers by pulling them backwards.

6) Close the dustproof cover of the quick couplers of the tractor. Cover the quick coupler of the disconnected

implement so that no dirt can penetrate.

Warning:

- Never connect or disconnect the implement hydraulic hose while the pressure in it is not released

or the engine is running. It is hard to connect and disconnect the hose and hydraulic fluid can be

sprayed from the hose, and get into your eyes or skin.

- Stop the engine and wear protective glasses and gloves before work.

TRACTOR CONTROLS

60

Summary of Contents for UTILIX CL

Page 1: ...OPERATOR S MANUAL UTILIX CL 01 2021 45 Tractor is Zetor Since 1946 55...

Page 3: ...2...

Page 9: ...NOTES 8...

Page 11: ...NOTES 10...

Page 39: ...NOTES 38...

Page 119: ...NOTES 118...

Page 125: ...NOTES 124...

Page 131: ...NOTES 130...

Page 134: ...133...