OPERATION

Page 2-5

The system is placed into Warm-Up Mode as follows:

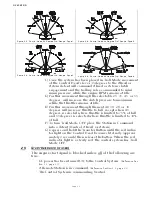

F) When the Control Head’s lever is returned to the Neutral

detent, the red LED will discontinue blinking and remain lit

steady. After one second in Neutral, the Processor will

automatically reset to normal operation with full control of

the clutches and engine.

G) The next movement of the Control Head’s lever will engage

the Ahead or Astern clutch (Normal Operation).

2-9

H

IGH

/L

OW

I

DLE

The Control System provides the input to the engine, so that it

may run at the standard Idle speed (typically adjusted at the gover-

nor or carburetor), or it can provide a second elevated Idle speed.

2-9.1

Low Idle

• The factory default setting is for Low Idle Only.

• When the System is initially powered-up, it will always com-

mand Low Idle, even when High Idle is selected.

2-9.2

High Idle

• If High Idle is desired, it may be programmed during Dock Tri-

als.

• High Idle is programmable up to a maximum setting of 20% of

Full Throttle.

• High Idle is automatically selected when in Warm-Up Mode.

2-9.3

Selecting Between High and Low Idle

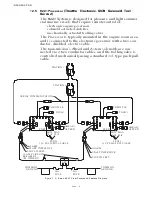

Figure 2-9: Control Head Warm-Up Mode

Figure 2-10: Control Head Normal Operating

Mode

A) At the Station-in-Command, ensure that

the Control Head’s lever is in the Neutral

detent position (refer to Figure 2-9:).

B) Depress and hold the transfer button.

C) After one second, move the Control

Head’s lever to the Ahead detent, while

continuing to hold the transfer button.

D)Now release the transfer button.

•The red LED indicator light will blink

slowly, indicating Warm-Up Mode is acti-

vated and the Clutch has remained at Neu-

tral.

E) The operator can start the engine, if

required, and increase the RPM through

the entire throttle range by moving the

Control Head’s lever forward through the

next 65 degrees.

WARNING: P

ERSONAL

I

NJURY

COULD

OCCUR

IF

THE

FOLLOWING

STEPS

ARE

NOT

FOLLOWED

EXACTLY

.

Summary of Contents for ClearCommand 9000 Series

Page 132: ......

Page 133: ...APPENDIX A...

Page 134: ......

Page 139: ......

Page 140: ...Page A 4...

Page 143: ......

Page 144: ...10...

Page 148: ...Page A 18...

Page 149: ...Page A 19 TEMPLATE...

Page 150: ...Page A 20...

Page 152: ...Page A 22...

Page 154: ...Page A 24...

Page 156: ...Page A 26...

Page 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Page 158: ...Page A 28...

Page 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Page 160: ...Page A 30...

Page 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Page 162: ...Page A 32...

Page 164: ...Page A 34...

Page 166: ...Page A 36...

Page 170: ...Page A 40...

Page 172: ...Page A 42...

Page 176: ...Page A 46...

Page 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Page 179: ...APPENDIX B...

Page 180: ......

Page 234: ...Appendix B 6...

Page 238: ...Appendix B 10...

Page 242: ...Appendix B 14...

Page 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Page 248: ......

Page 250: ...Page ii Table of Contents...

Page 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Page 265: ...APPENDIX C...

Page 266: ......

Page 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Page 268: ...Appendix C 2...

Page 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Page 270: ...Appendix C 4...

Page 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Page 272: ...Appendix C 6...