INSTALLATION

Page4-14

J) Insert the cable ends through the liquid tight connectors

and tighten the nuts.

K) Secure the cables internally using a Clamp as shown in

Figure 4-13:, page 4-9. Make certain that the drain wire

makes contact with the Clamp’s metallic surface.

L) Clip the exposed drain wires flush with the Clamps.

M)Connect the conductors to the terminal block as listed in

Table 4-4:.

4-4.7 Locations 10 and 11 Installation

4-4.7.1 Clutch Cable (Location 10)

A single four-conductor cable must connect the two Shift

cables to the Processor through a 12 pin plug.

4-4.7.1.1 Processor Termination

A) Install a liquid tight connector into hole no.10.

B) Run a 32 inch (0,82m) piece of four-conductor

cable through the liquid tight connector and

tighten, leaving 16 inches (0,41m) outside of the

Processor.

C) Strip back 4 inches (101,6mm) of the PVC jacket

inside the Processor.

D) Slide a 1 inch (24,5mm) piece of heat shrink over

the end of the cable as shown in Figure 4-20:.

E) Strip back 3/8 inch (9,53mm) from the four con-

ductors and connect to the Processor as shown in

Table 4-5:., page 4-15

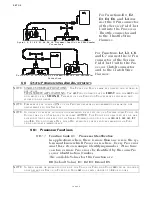

Table 4-4: Processor Circuit Board Terminal Strip Color Coded Connections for Tachometer

Termination

Conductor Color

Description

Notes

TB9-1

Red

Sensor Supply (+9VDC)

Required when Open Collector (i.e., Hall Effect

Sensors) only

TB9-2

Green

AC Type Tachometer Input The green wire connects here when AC Type

Tach Sensors (i.e., Mechanical Senders, Magnetic

Pickup, Alternator AC, etc.) are being used.

TB9-3

Green

Open Collector Tachometer

Input

The green wire connects here when an Open Col-

lector Type Tach Sender is used.

TB9-4

Black

Return for Tachometer

Input

Negative connection for both types of Senders.

Clamp

Silver

Drain wire (Shield) connec-

tion.

Connection made at Processor side only.

Figure 4-20: Clutch Cable Heat Shrink in Processor

Heat Shrink

1 inch

(25,4mm)

4 inches

(101,6mm)

3/8 inch

(9,53mm)

Summary of Contents for ClearCommand 9000 Series

Page 132: ......

Page 133: ...APPENDIX A...

Page 134: ......

Page 139: ......

Page 140: ...Page A 4...

Page 143: ......

Page 144: ...10...

Page 148: ...Page A 18...

Page 149: ...Page A 19 TEMPLATE...

Page 150: ...Page A 20...

Page 152: ...Page A 22...

Page 154: ...Page A 24...

Page 156: ...Page A 26...

Page 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Page 158: ...Page A 28...

Page 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Page 160: ...Page A 30...

Page 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Page 162: ...Page A 32...

Page 164: ...Page A 34...

Page 166: ...Page A 36...

Page 170: ...Page A 40...

Page 172: ...Page A 42...

Page 176: ...Page A 46...

Page 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Page 179: ...APPENDIX B...

Page 180: ......

Page 234: ...Appendix B 6...

Page 238: ...Appendix B 10...

Page 242: ...Appendix B 14...

Page 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Page 248: ......

Page 250: ...Page ii Table of Contents...

Page 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Page 265: ...APPENDIX C...

Page 266: ......

Page 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Page 268: ...Appendix C 2...

Page 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Page 270: ...Appendix C 4...

Page 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Page 272: ...Appendix C 6...