SET UP

Page5-12

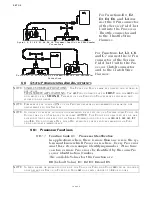

5-6.2.1.5 Function Code E7 – Synchronization

5-6.2.2 Throttle Servo Functions

This section along with Section 5-6.2.1 Throttle Basic Func-

tions, allows the adjustment of Throttle Servo related items:

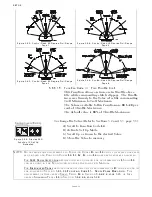

5-6.2.2.1 Function Code E0 – Throttle Servo Direction

Figure 5-19: Display LED Function E4 Set Up

Activated

Example:

A Value of

50.0

will allow 50% of Throttle

Maximum when commanding Astern. The Value

selected is a matter of personal preference.

To change the Value (Refer to Sections 5-2 and 5-3,

page 5-5):

A) Scroll to Function Code E4.

B) Activate Set Up Mode.

C) Scroll Up or Down to the desired Value.

D) Store the Value to memory.

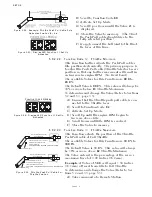

Figure 5-20: Display LED Function E7 Set Up

Activated

This Function Code selects the type of Synchroniza-

tion, if Synchronization is required. The types are

described in Section 2-10, page 2-6.

The available Values for this Function are:

00

Equal Throttle (Open Loop) Synchronization

01

Active (Closed Loop) Synchronization (reverts to Equal

Throttle Synch if there is no Tachometer Sensor signal)

02

No Synchronization

(Default Value)

03

Active (Closed Loop) Synchronization (reverts to no Syn-

chronization if there is no Tachometer Sensor signal)

The Default Value is

02

.

To change the Value (Refer to Sections 5-2 and 5-3,

page 5-5):

A) Scroll to Function Code

E7

.

B) Activate Set Up Mode.

C) Scroll Up or Down to the desired Value.

D) Store the Value to memory.

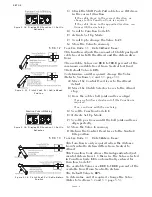

Figure 5-21: Throttle Push-Pull Cable Orientation

This Function determines if the Throttle Push-

Pull cable is fully extended or retracted when

at Idle.

The available Values for this Function are:

20

Fully Retracted [Pull] at Idle (Default

Value)

21

Fully Extended [Push] at Idle

To determine and change the Value (Refer to

Sections 5-2 and 5-3, page 5-5):

A) Ensure that the engine’s Governor or Car-

buretor lever is at the Idle position.

• If the Throttle Push-Pull cable’s ball joint is

close to the Throttle lever’s position, no

change is required to this Function Code.

• If the Throttle Push-Pull cable’s ball joint is

at the opposite side of the lever’s position,

continue with the next step.

Summary of Contents for ClearCommand 9000 Series

Page 132: ......

Page 133: ...APPENDIX A...

Page 134: ......

Page 139: ......

Page 140: ...Page A 4...

Page 143: ......

Page 144: ...10...

Page 148: ...Page A 18...

Page 149: ...Page A 19 TEMPLATE...

Page 150: ...Page A 20...

Page 152: ...Page A 22...

Page 154: ...Page A 24...

Page 156: ...Page A 26...

Page 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Page 158: ...Page A 28...

Page 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Page 160: ...Page A 30...

Page 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Page 162: ...Page A 32...

Page 164: ...Page A 34...

Page 166: ...Page A 36...

Page 170: ...Page A 40...

Page 172: ...Page A 42...

Page 176: ...Page A 46...

Page 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Page 179: ...APPENDIX B...

Page 180: ......

Page 234: ...Appendix B 6...

Page 238: ...Appendix B 10...

Page 242: ...Appendix B 14...

Page 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Page 248: ......

Page 250: ...Page ii Table of Contents...

Page 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Page 265: ...APPENDIX C...

Page 266: ......

Page 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Page 268: ...Appendix C 2...

Page 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Page 270: ...Appendix C 4...

Page 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Page 272: ...Appendix C 6...