SET UP

Page5-13

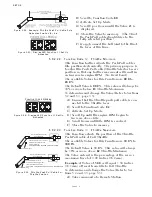

5-6.2.2.2 Function Code

E2

– Throttle Minimum

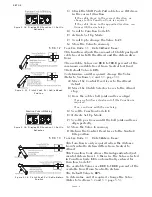

5-6.2.2.3 Function Code

E3

– Throttle Maximum

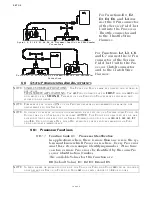

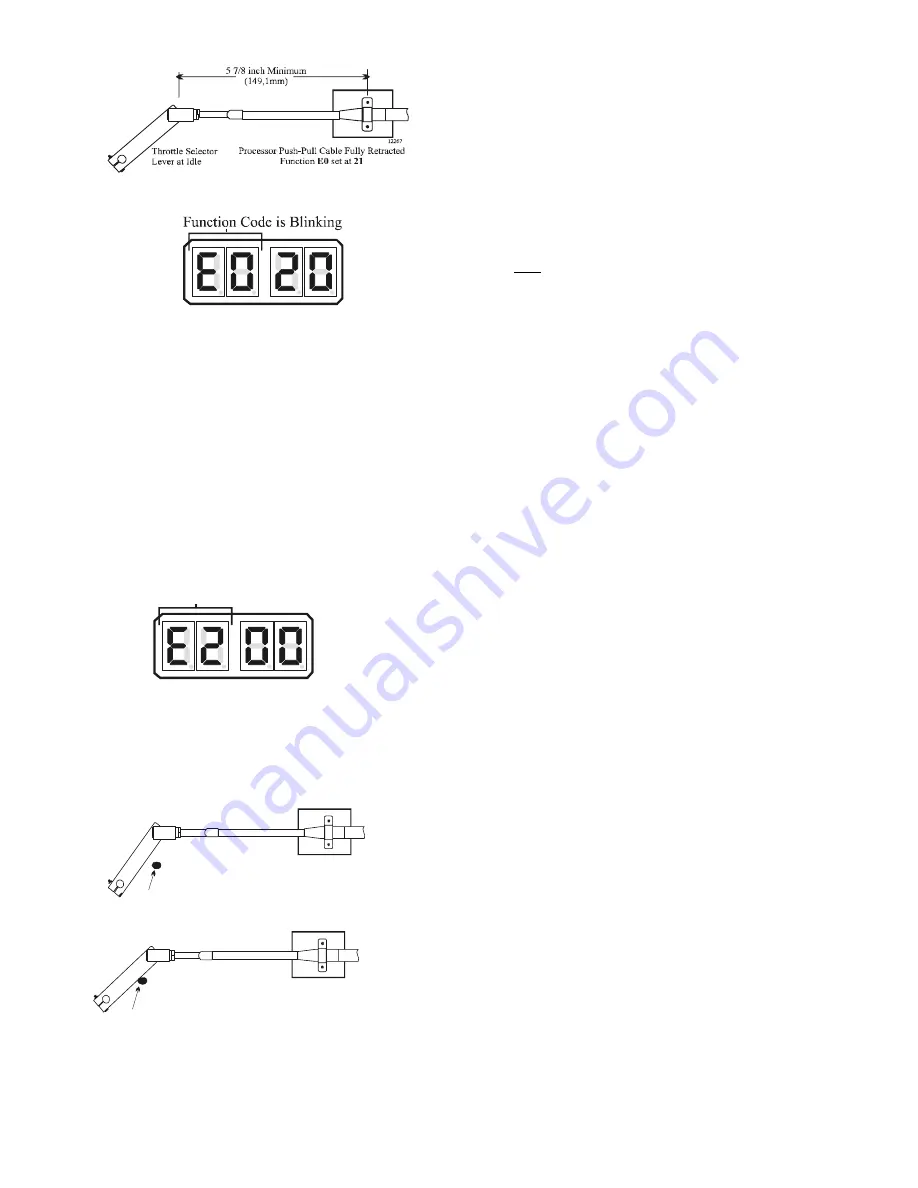

Figure 5-22: Example: Throttle Push-Pull Cable Fully

Retracted Position for Idle

Figure 5-23: Display LED Function

E0

Set Up

Activated

B) Scroll to Function Code

E0

.

C) Activate Set Up Mode.

D) Scroll Up or Down until the Value

21

is

displayed.

E) Store the Value to memory. (The Throt-

tle Push-Pull cable should drive to the

fully retracted position.)

F) Do not connect the ball joint to the throt-

tle lever at this time.

Figure 5-24: Display LED Function E2 Set Up

Activated

This Function further adjusts the Push-Pull cable’s

Idle position electronically. The primary purpose is

to adjust the Push-Pull cable/Throttle Selector Lever’s

position so that any further movement will result in

an increase in engine RPM. (No Dead-band)

The available Values for this Function are

00.0

to

20.0

%.

The Default Value is

00.0

%. This value will always be

10% or more below

E3

Throttle Maximum.

To determine and change the Value (Refer to Sections

5-2 and 5-3, page 5-5):

A) Ensure that the Throttle push-pull cable is con-

nected to the Throttle lever.

B) Scroll to Function Code

E2

.

C) Activate Set Up Mode.

D) Scroll Up until the engine RPM begins to

increase above Idle.

E) Scroll Down until Idle RPM is reached.

F) Store the Value to memory.

Figure 5-25: Throttle Push-Pull Cable Full

Throttle Position

This Function adjusts the position of the Throttle

Push-Pull cable at Full Throttle.

The available Values for this Function are

10.0

% to

100.0

%.

The Default Value is

33.0

%. This value will always

be 10% or more above

E2

Throttle Minimum.

The Value entered is the percentage of the servo’s

maximum travel of 3.00 inches (76,2mm).

Example:

A Value of

50.0

, will equal 1.50 inches

(38,1mm) of travel from Idle to Full Throttle.

To determine and change the Value (Refer to Sec-

tions 5-2 and 5-3, page 5-5):

A) Take command at a Remote Station.

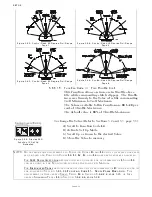

Function Code is Blinking

Throttle Selector Lever is not at

Full Throttle and against the

Full Throttle Stop

FUNCTION CODE

NEED TO BE ADJUSTED

E3

Processor Push-Pull Cable

Fully Retracted

12267

Full Throttle Stop

Throttle Selector Lever at

Full Throttle and Laying Firmly

against the Full Throttle Stop

FUNCTION CODE

DOES NOT NEED TO BE ADJUSTED

E3

Processor Push-Pull Cable

Fully Retracted

12267

Full Throttle Stop

Summary of Contents for ClearCommand 9000 Series

Page 132: ......

Page 133: ...APPENDIX A...

Page 134: ......

Page 139: ......

Page 140: ...Page A 4...

Page 143: ......

Page 144: ...10...

Page 148: ...Page A 18...

Page 149: ...Page A 19 TEMPLATE...

Page 150: ...Page A 20...

Page 152: ...Page A 22...

Page 154: ...Page A 24...

Page 156: ...Page A 26...

Page 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Page 158: ...Page A 28...

Page 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Page 160: ...Page A 30...

Page 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Page 162: ...Page A 32...

Page 164: ...Page A 34...

Page 166: ...Page A 36...

Page 170: ...Page A 40...

Page 172: ...Page A 42...

Page 176: ...Page A 46...

Page 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Page 179: ...APPENDIX B...

Page 180: ......

Page 234: ...Appendix B 6...

Page 238: ...Appendix B 10...

Page 242: ...Appendix B 14...

Page 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Page 248: ......

Page 250: ...Page ii Table of Contents...

Page 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Page 265: ...APPENDIX C...

Page 266: ......

Page 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Page 268: ...Appendix C 2...

Page 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Page 270: ...Appendix C 4...

Page 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Page 272: ...Appendix C 6...