Operating

Instructions

Initial Installation

2K800/2K801/2K802

12

EN 4161.758.103m – 2015-10

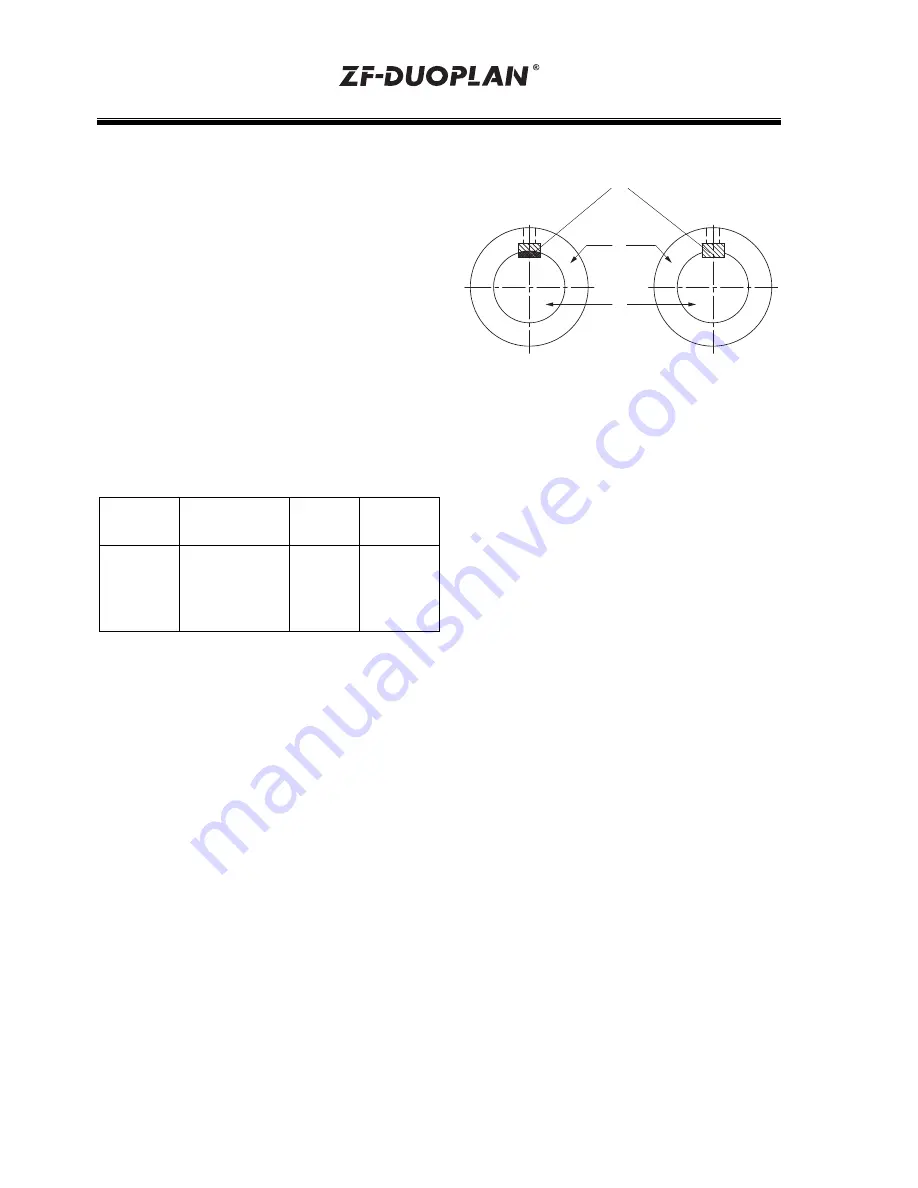

Semi-key balancing

Full-key balancing

3.2

Balancing

The hubs (2) come with a keyway (1) for

transmitting power from the motor shaft (3) as

standard.

There are two balancing types for the motor

and gearbox: Semi-key and full-key, which are

described in more detail in DIN ISO 8821.

It must be ensured that the hub is balanced in the

same way as the motor.

This is why it is very important to indicate the

motor data, dimensions and balancing type when

ordering.

Motor output shafts with standard fitted key

in accordance with EN 50347: 2001

Gearbox

type

Shaft diameter

Fitted

key

Fitted key

length

2K800

2K801

2K802

60 mm

65 mm

75 mm

80 mm

A18x11

A18x11

A20x12

A22x14

125 mm

125 mm

125 mm

140 mm

NOTE

In the case of motor shafts with open ends of the

keyway, the parallel key is to be glued into the

groove in order to avoid axial migration of the

parallel key and/or the hub.

3.2.1

Semi-key balancing

In semi-key balancing, the keyway is filled with

a balance compensation corresponding to

approximately half a key, shape B by default. This

is based on the original key, shape, length and

position used by the motor manufacturer and is

defined as a counterweight. In semi-key balancing

– in contrast to full-key balancing – the joint

passes through a shared component. This means

imbalance can arise after assembly due to

tolerance factors.

As a result, it is recommended that rebalancing

should be performed after the joined parts have

been assembled.

3.2.2

Full-key balancing

In full-key balancing, the motor shaft is balanced

with a full key whereas the hub is not. The key,

shape, length and position are not important in

this case.

1

2

3