Maintenance and Installation Instructions

Edition 11.07.2006

18 of 30

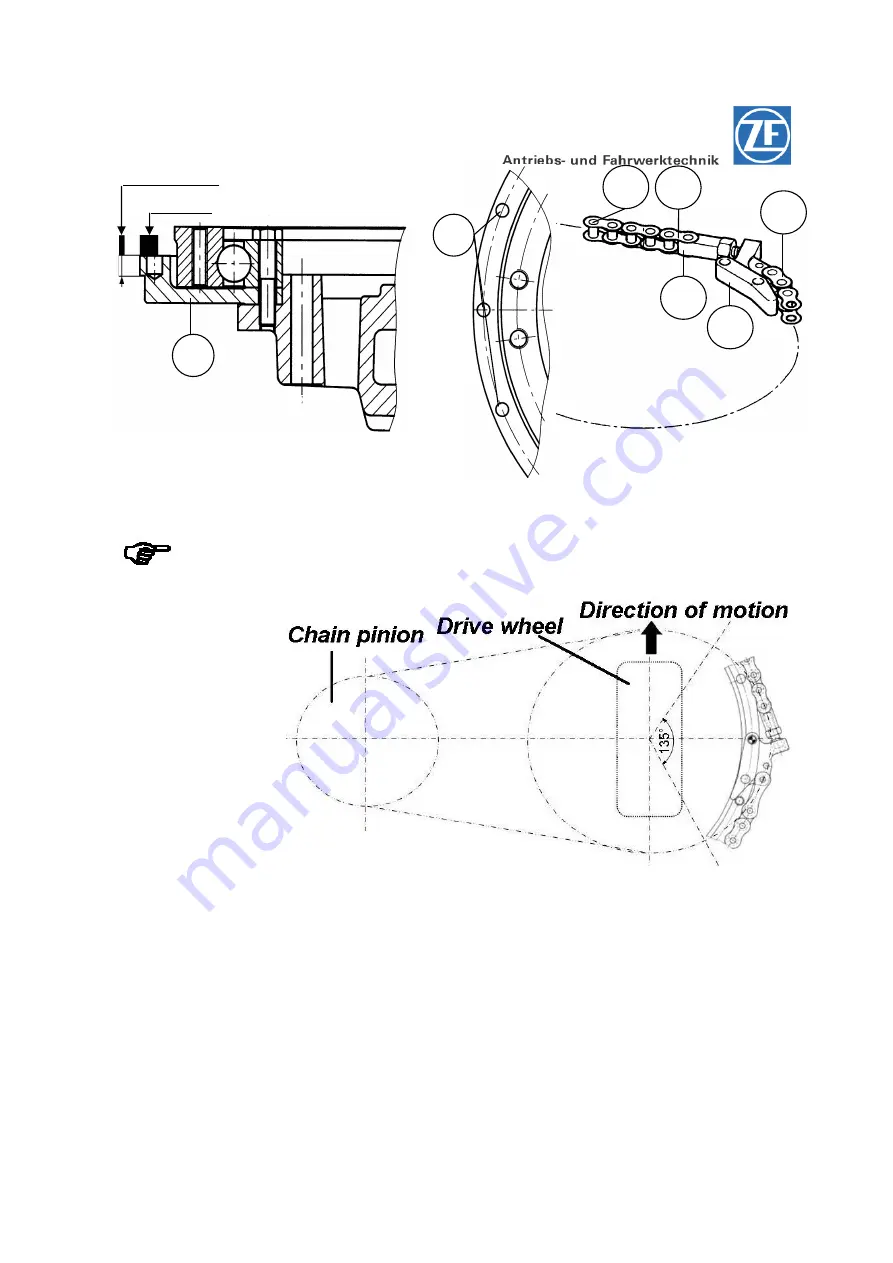

Figure 13

Within an area of approx. 135° around the chain tensioner only riveted

connecting elements (chain joints) are allowed to be used.

Drive wheel and wheel

shaft respectively must

be aligned in direction of

motion.

The chain tensioner

should be mounted

opposite of the steering

pinion. This ensures that

there is an equal steering

angle towards both sides.

Figure 14

Mounting of the pivoted connection

(see Fig.05, Page 12

)

1. The centering and supporting face for the chain flange has to be clean.

2. Pay attention that no foreign substances or cleaning agents get through the threaded holes (Item

01) of the mounting construction (hole pattern of the housing) inside the transmission.

3. Place the chain flange (Item 02) and rotate it, so that the boltholes in the chain flange are aligned

with the threaded holes of the mounting construction.

4. By means of a plastic tip hammer install the chain flange until contact is obtained.

5. Put on the pivoted bogie bearing (Item 03) with the correct side and rotate it so that the boltholes

in the pivoted bogie bearing are aligned with the hole pattern of the flange and the housing.

6. Fasten the pivoted bogie bearing and the chain flange on the mounting construction by means

hexagon screws M8x40 (Item 04).

02

Plane face

Chain guideway

07

04

06

03

01

05