Maintenance and Installation Instructions

Edition 11.07.2006

22 of 30

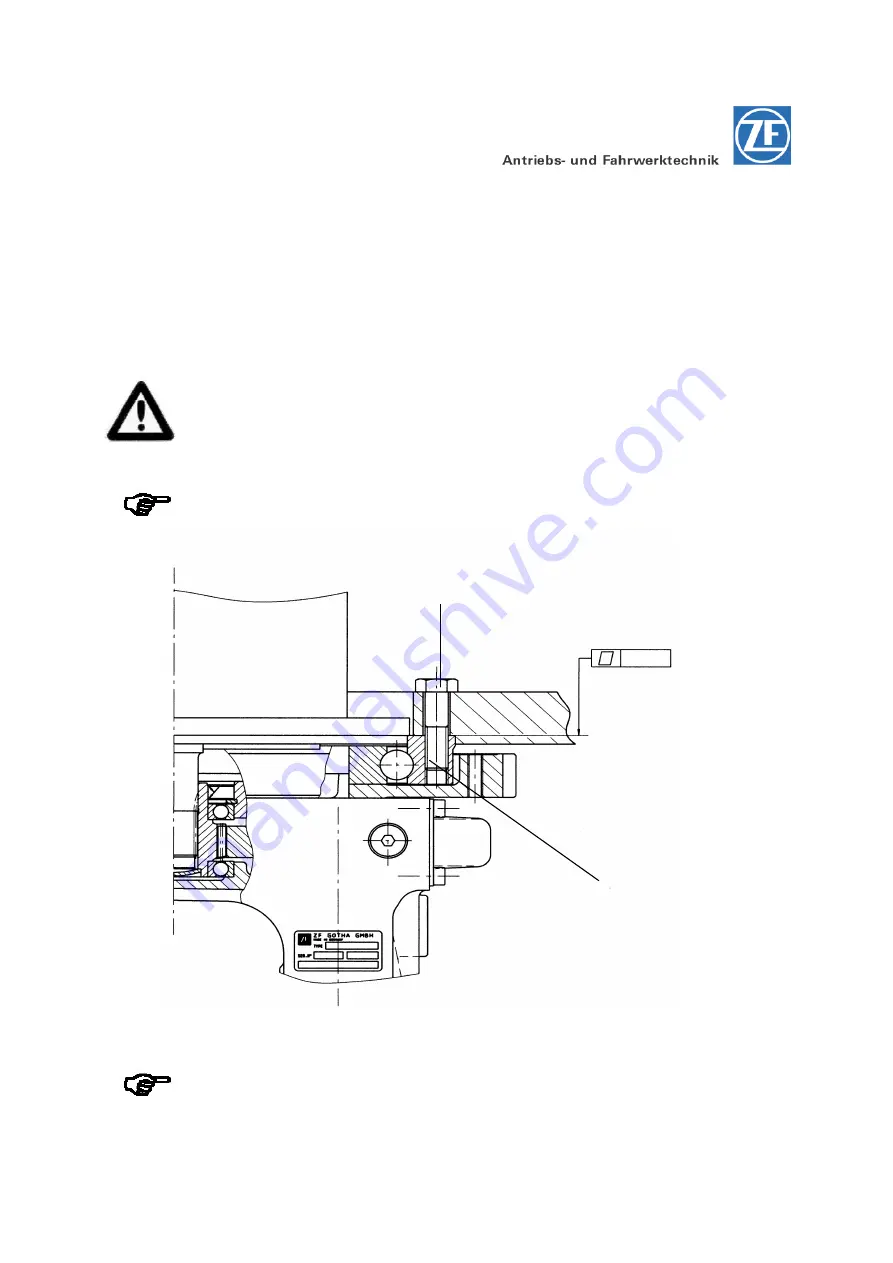

Transmission Attachment to the Mounting Construction in the Vehicle

For economy reasons the cross sections of the pivoted bogie bearings are kept very small in comparison

with the diameter. This requires a rigid and torsion-resistant mounting construction for these bearings.

Additionally the supporting face for the pivoted bogie bearings and mounting of the same must also

provide the maximum evenness or flatness. (see Fig. 17)

The supporting face in the vehicle requires a mechanical machining. Inadmissible distortions or

deformations during fastening of the screws occur due to uneven locating on the frame plate or

unevenness in the locating area of the pivoted bogie bearing.

The pivoted bogie bearing must support evenly on the whole surface of the

mounting construction. If this requirement is not fulfilled the service life of

the pivoted bogie bearing reduces. Additionally, the reliability in service is

put at risk.

Shape alternatives of the locating face require a written approval by ZF,

which however will only be given after a preceding installation investigation.

Figure 17

Please observe the specified vehicle mounting dimensions indicated in the

corresponding installation drawing of the unit!

0.15

M 12

Screw-in depth

min 15 mm