Maintenance and Installation Instructions

Edition 11.07.2006

8 of 30

Installation

General Instructions

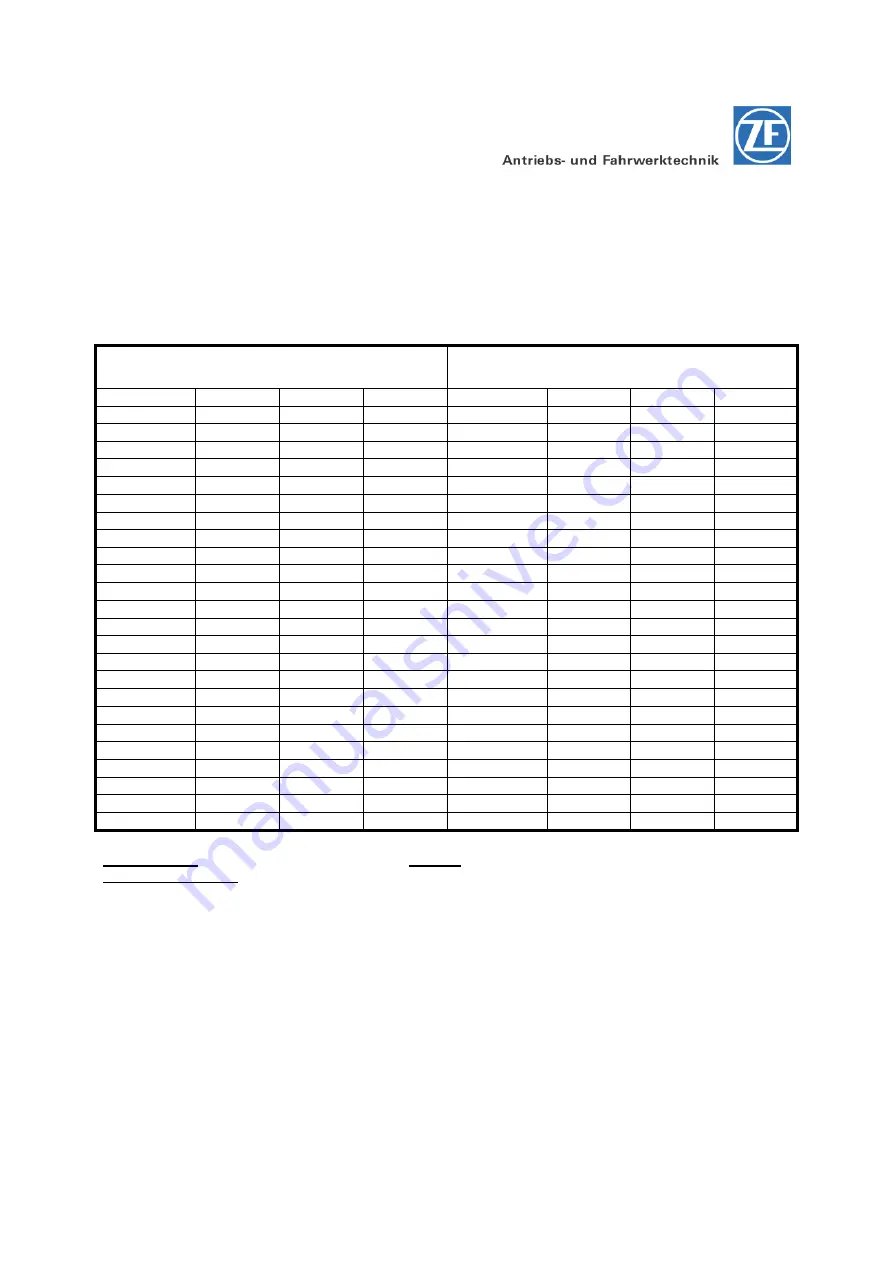

Torque limits in Nm for screws to ZF Standard 148

Torque limits, if not especially indicated, can be taken from the following list:

Metric ISO-Standard thread DIN 13,

Sheet 13

Metric ISO-Fine thread DIN 13,

Sheet 13

Size

8.8

10.9

12.9

Size

8.8

10.9

12.9

M 4

2.8

4.1

4.8

M 8x1

24

36

43

M 5

5.5

8.1

9.5

M 9x1

36

53

62

M 6

9.5

14

16.5

M 10x1

52

76

89

M 7

15

23

28

M 10x1.25

49

72

84

M 8

23

34

40

M 12x1.25

87

125

150

M 10

46

68

79

M 12x1.5

83

120

145

M 12

79

115

135

M 14x1.5

135

200

235

M 14

125

185

215

M 16x1.5

205

300

360

M 16

195

280

330

M 18x1.5

310

440

520

M 18

280

390

460

M 18x2

290

420

490

M 20

390

560

650

M 20x1.5

430

620

720

M 22

530

750

880

M 22x1.5

580

820

960

M 24

670

960

1100

M 24x1.5

760

1100

1250

M 27

1000

1400

1650

M 24x2

730

1050

1200

M 30

1350

1900

2250

M 27x1.5

1100

1600

1850

M 33

1850

2600

3000

M 27x2

1050

1500

1800

M 36

2350

3300

3900

M 30x1.5

1550

2200

2550

M 39

3000

4300

5100

M 30x2

1500

2100

2500

M 33x1.5

2050

2900

3400

M 33x2

2000

2800

3300

M 36x1.5

2700

3800

4450

M 36x3

2500

3500

4100

M 39x1.5

3450

4900

5700

M 39x3

3200

4600

5300

Friction value

:

µ

tot. 0.12

for screws and nuts

without

after-treatment, as well as phosphatized nuts.

Tightened by hand!