4.2 INTERMEDIATE AND REVERSAL SHAFT

4.2.1 Mounting inner races of tapered

roller bearings

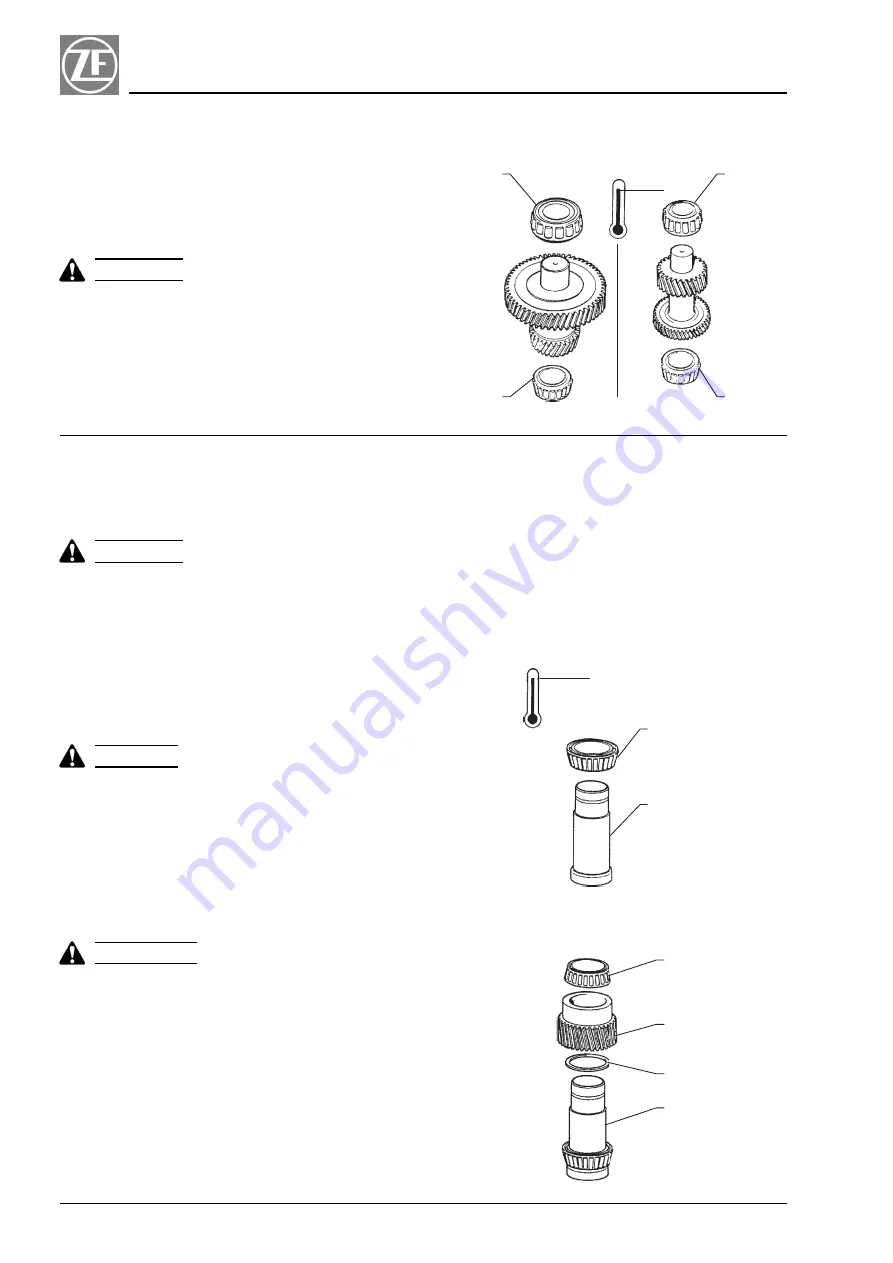

Heat inner races of tapered roller bearings (item 1 and 2,

Fig. 2-1) to approx. 120ëC (248ëF) and push them onto the

intermediate or reversal shaft upagainst the shaft collar.

|

WARNING

|

Handle heated tapered roller bearing inner races

only with protective gloves!

When the inner races have cooled down, drive them

carefully against the collar using a brass punch.

NOTE

Apply copper/brass punch on inner race and not on

the rollers.

4.3 OUTPUT SHAFT

4.3.1 Preparations for assembly

Finish press fit on output shaft and gear with a very fine

emery paper. Then clean both parts thoroughly.

|

WARNING

|

Cleaners and solvents can be toxic and potentually

harmful without proper ventilation. Use caution

when using such cleaners.

Always wear protective gloves and glasses!

4.3.2 Mounting inner race of tapered roller

bearing

Heat inner races of tapered roller bearings (item 1 and

2, Fig. 3-1) to approx. 120ë (248ëF) and push them onto

output shaft up against shaft collar.

|

CAUTION

|

Handle heated tapered roller bearing inner races

only with protective gloves!

When the inner races have cooled down, drive them

carefully against the collar using a brass punch.

NOTE

Apply copper/brass punch on inner race and not on

the rollers.

4.3.3 Pressing the gear on

|

ATTENTION

|

ONLY ZF 63 IV: with transmission ratio of 1.3 to 2.0

the ring (item 1 Fig. 3-2) must be mounted

.

Provide press fit of output shaft with a thin coat of

glycerol.

.

With a transmission ratio of 1.3 to 2.0, a washer

(item 1, Fig. 3-2) should be inserted.

.

Press gear (item 2, Fig. 3-2) on shaft (item 3, Fig. 3-

2), by means of a hydraulic press.

Pressing force required: 200 kN

After having pressed the gear on, mount second in-

ner race of bearing (item 4, Fig. 3-2) as described

under 3.2.

20

Repair Manualand Spare Parts List

Section 4

1

120

˚C

248

˚F

2

1

2

FIG. 2 - 1

2

1

120

˚C

248

˚F

FIG. 3 - 1

4

2

1

3

FIG. 3 - 2