26

Repair Manualand Spare Parts List

Section 4

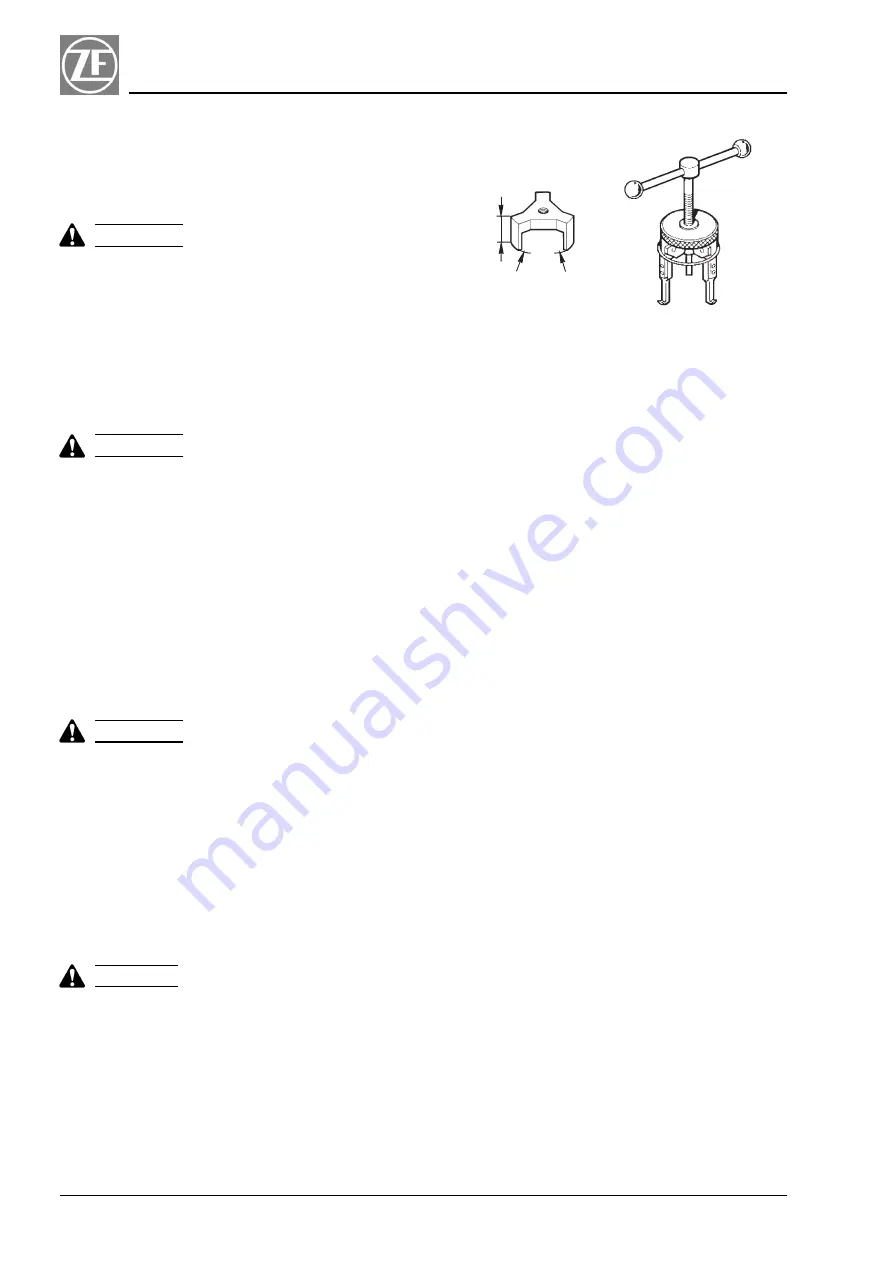

ADAPTER FOR

BASIC UNIT 454422

50

A

B

BASIC UNIT

FIG. 5 - 7c

e) Pull outer races of bearings out of the "drive" hous-

ing half using the extracting unit (Fig. 5-7c) or heat

the half of the housing in an oven to approx.

120ëC (248ëF) and remove the outer races of bear-

ings together with shims.

|

WARNING

|

Handle heated housing half and outer race only with

protective gloves!

NOTE.

Make sure to keep the shims with each outer race

and not mix them together.

4.5.8 Final assembly of the housing

a) Heat input side of the housing in an oven to approx.

120ëC (248 ëF).

|

WARNING

|

Handle heated housing only with protective gloves!

b) Insert the required shims for proper pretension into

bearings bore under bearing outer race.

c) Insert outer races of bearings. When the housing

half has reached ambiet temperature, drive outer

races of bearings up to the stop, using a copper

punch.

d) Insert gears again.

e) Fill space between seal and dust lips of shaft seal

rings with a high quality bearing grease (KLUEBER

STABURAGS NBU 30).

f) Apply a thin coat of Loctite 518 on mating face of "in-

put" housing half and join both housing halves.

|

WARNING

|

The necessary time for a complete polymerization is

5 hours: we recommend therefore to clean carefully

the mating surfaces with Loctite 7063 cleaner be-

fore applying the Loctite 518 and wait the requested

time before the spin test.

g) Drive parallel pins into housing to align housing

halves, before tightening.

h) Apply Loctite 243 on to mounting bolts (item 2 and 3,

Fig. 5-7a) and torque them to 40 Nm (30 ft lb).

i) Check pretension of bearings accord-ing to sections

5.4, 5.5 and 5.7.

|

CAUTION

|

There must be no measurable bearing clearance.

j) Only for transmission size i=2.0 and i=2.5

ZF 63 IV. Press radialshaft seal(item 1, Fig. 4-3b)

with a suitable pipe into the "drive" housing half.

NOTE

The sealing lip on the radial shaft seal show to the

inside of the housing. The radial shaft seal must

be so adjusted that the sealing lip does not bear

on the former running point of the shaft.

k) Mount the output flange again. (see chapter 5.6).