14

14

GB

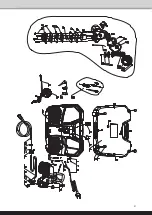

Device description

1. Transport handle

2. ON/OFF switch

3. Compressor housing

4. Quick-lock coupling

5. Pressure hose

6. Power cord

A

Universal adapter, for valves with diameter ca.

6 mm

B

Universal adapter, for valves with diameter ca.

9 mm

C

Adapter for H, J, K

D

Blow-out adapter

E

Valve adapter, e.g. For bicycle valves

F

Ball needle

G

Tyre pressure gauge

H

Deflating adapter

J

Screw-on valve adapter

K

Universal adapter

Unpacking

•

Open the packaging and remove the device care-

fully.

•

Remove the packaging material as well as the

packaging and transport bracing (if available).

•

Check that the delivery is complete.

•

Check the device and accessory parts for trans-

port damage.

•

If possible, store the packaging until the warranty

period has expired.

m

ATTENTION!

The device and packaging materials are not toys!

Children must not be allowed to play with plas-

tic bags, film and small parts! There is a risk of

swallowing and suffocation!

Intended use

The compressor is designed to generate com-

pressed air for compressed-air driven tools which

can be driven with an air volume of up to approx.

180 l/min (e.g. tire infl ator, blow-out pistol and paint

spray gun). Due to the limited air output it is not pos-

sible to use the compressor to drive tools with very

high air consumption (for example orbital sanders,

rod grinders and hammer screwdrivers).

The equipment is to be used only for its prescribed

purpose. Any other use is deemed to be a case of

misuse. The user / operator and not the manufac-

turer will be liable for any damage or injuries of any

kind caused as a result of this.

Introduction

MANUFACTURER:

scheppach

Fabrikation von Holzbearbeitungsmaschinen GmbH

Günzburger Straße 69

D-89335 Ichenhausen

DEAR CUSTOMER,

we hope your new tool brings you much enjoyment

and success.

NOTE:

According to the applicable product liability laws, the

manufacturer of the device does not assume liability

for damages to the product or damages caused by

the product that occurs due to:

• Improper handling,

• Non-compliance of the operating instructions,

• Repairs by third parties, not by authorized service

technicians,

• Installation and replacement of non-original spare

parts,

•

Application other than specified,

• A breakdown of the electrical system that occurs

due to the non-compliance of the electric regu-

lations and VDE regulations 0100, DIN 57113 /

VDE0113.

WE RECOMMEND:

Read through the complete text in the operating in-

structions before installing and commissioning the

device. The operating instructions are intended to

help the user to become familiar with the machine

and take advantage of its application possibilities in

accordance with the recommendations. The operat-

ing instructions contain important information on how

to operate the machine safely, professionally and

economically, how to avoid danger, costly repairs, re-

duce downtimes and how to increase reliability and

service life of the machine.

In addition to the safety regulations in the operating

instructions, you have to meet the applicable regula-

tions that apply for the operation of the machine in

your country. Keep the operating instructions pack-

age with the machine at all times and store it in a

plastic cover to protect it from dirt and moisture.

Read the instruction manual each time before op-

erating the machine and carefully follow its informa-

tion. The machine can only be operated by persons

who were instructed concerning the operation of the

machine and who are informed about the associated

dangers. The minimum age requirement must be

complied with.

In addition to the safety notices contained in this

operating manual and the particular instructions for

your country, the generally recognised technical reg-

ulations for the operation of identical devices must

be complied with.

Summary of Contents for YELLOW PROFILINE YPL 183-2 KIT

Page 2: ...2...

Page 3: ...3 1 1 3 2 7 G H J K B C D E F A 4 6 8 C H J K...

Page 4: ...4 5 3 4 4 4 6 8 5 4 2 5 7...

Page 5: ...5...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...