15

15

GB

11

Avoid inadvertent starting

–

Make sure that the switch is switched off when

plugging the plug into an outlet.

12

Use extension cables for outdoors

–

Only use approved and appropriately identified

extension cables for use outdoors.

–

Only use cable reels in the unrolled state.

13

Remain attentive

–

Pay attention to what you are doing. Remain

sensible when working. Do not use the electric

tool when you are distracted.

14

Check the electric tool for potential damage

–

Protective devices and other parts must be

carefully inspected to ensure that they are fault-

free and function as intended prior to continued

use of the electric tool.

–

Check whether the moving parts function fault-

lessly and do not jam or whether parts are dam-

aged. All parts must be correctly mounted and

all conditions must be fulfilled to ensure fault-

free operation of the electric tool.

–

Damaged protective devices and parts must be

properly repaired or replaced by a recognised

workshop, insofar as nothing different is speci-

fied in the operating manual.

–

Damaged switches must be replaced at a cus-

tomer service workshop.

–

Do not use any faulty or damaged connection

cables.

–

Do not use any electric tool on which the switch

cannot be switched on and off.

15

Have your electric tool repaired by a qualified

electrician

–

This electric tool conforms to the applicable

safety regulations. Repairs may only be per-

formed by an electrician using original spare

parts. Otherwise accidents can occur.

16

Important!

–

For your own safety you must only use the ac-

cessories and additional units listed in the oper-

ating instructions or recommended or specified

by the manufacturer. The use of mounted tools

or accessories other than those recommended

in the operating instructions or catalog may

place your personal safety at risk.

17

Noise

–

Wear ear muffs when you use the compressor.

18

Replacing the power cable

–

To prevent hazards, leave the replacement of

damaged power cables strictly to the manufac-

turer or a qualified electrician. There is a risk of

electric shock!

19

Inflating tires

–

ATTENTION!

The manometer has not been of-

ficially calibrated! Directly after inflating tires,

check the pressure with a suitable pressure

gauge, for example at your filling station.

20

Roadworthy compressors for building site operations

–

Make sure that all lines and fittings are suitable

for the maximum permissible operating pressure

of the compressor.

Please note that our equipment has not been de-

signed for use in commercial, trade or industri-

al applications. Our warranty will be voided if the

equipment is used in commercial, trade or industrial

businesses or for equivalent purposes.

Safety information

m

Attention!

The following basic safety actions must

be taken when using this compressor in order to pro-

tect the user from electric shocks and the risk of injury

and fi re. Read and follow these instructions before

using the equipment.

Safe work

1

Keep the work area orderly

–

Disorder in the work area can lead to accidents.

2

Take environmental influences into account

–

Do not expose electric tools to rain.

–

Do not use electric tools in a damp or wet envi-

ronment. There is a risk of electric shock!

–

Make sure that the work area is well-illuminated.

–

Do not use electric tools where there is a risk of

fire or explosion.

3

Protect yourself from electric shock

–

Avoid physical contact with earthed parts (e.g.

pipes, radiators, electric ranges, cooling units).

4

Keep children away

–

Do not allow other persons to touch the equipment

or cable, keep them away from your work area.

5

Securely store unused electric tools

–

Unused electric tools should be stored in a dry,

elevated or closed location out of the reach of

children.

6

Do not overload your electric tool

–

They work better and more safely in the speci-

fied output range.

7

Wear suitable clothing

–

Do not wear wide clothing or jewellery, which can

become entangled in moving parts.

–

Rubber gloves and non-slip shoes are recom-

mended when working outdoors.

–

Tie long hair back in a hair net.

8

Do not use the cable for purposes for which it is

not intended

–

Do not use the cable to pull the plug out of the

outlet. Protect the cable from heat, oil and sharp

edges.

9

Take care of your tools

–

Keep your compressor clean in order to work

well and safely.

–

Follow the maintenance instructions.

–

Check the connection cable of the electric tool

regularly and have it replaced by a recognised

specialist when damaged.

–

Check extension cables regularly and replace

them when damaged.

10

Pull the plug out of the outlet

–

During non-use of the electric tool or prior to

maintenance and when replacing tools such as

saw blades, bits, milling heads.

Summary of Contents for YELLOW PROFILINE YPL 183-2 KIT

Page 2: ...2...

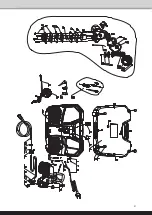

Page 3: ...3 1 1 3 2 7 G H J K B C D E F A 4 6 8 C H J K...

Page 4: ...4 5 3 4 4 4 6 8 5 4 2 5 7...

Page 5: ...5...

Page 20: ...20...

Page 21: ...21...

Page 22: ...22...