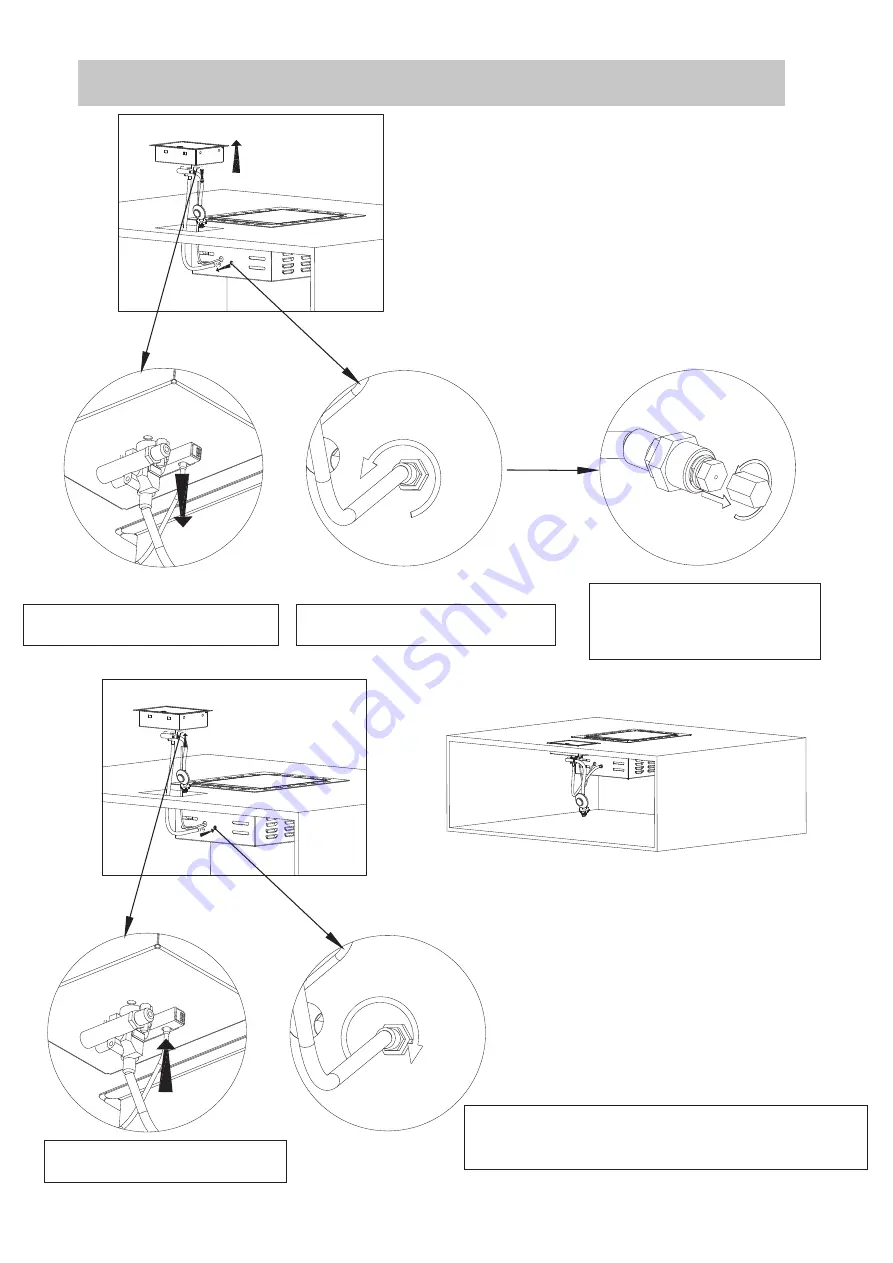

Step 1:Disconnect ignition wire from

the control box as above shown

Step 2:Disconnect the corrugated

pipe from the burner as above shown

Step 3:Disconnect the LP

injector, leaving the 1.75mm

NG exposed and in place as

shown above.

Step 4

:

Reconnect

the

ignition

wire

to

the

control

box

.

Step 5

:

Reconnect the corrugated pipe that

now holds the new 1.75 mm injector back in

place into the side burner.

13

TECHNICAL INFORMATION: Natural Gas Conversion (continued)

Summary of Contents for GRAND TURBO ZGGTSBBIL

Page 1: ...ZGGTSBBIL GRAND TURBO BARBEQUE DROP IN BUILD IN SIDE BURNER appliance 1 Natural Gas ...

Page 3: ...EXPLODED VIEW carton 3 Most parts already pre assembled in the factory ...

Page 4: ...4 OUTER CADOU24621435NG NG INJECTOR INNER ...

Page 16: ...Burnerseasilyextinguishedinlowwind firebox 16 appliance ...

Page 18: ...Firebox inner firebox outer lid and control box 18 C ...

Page 19: ...19 ...