3D

Limit ON / OFF

see Controller Setup / Limit

5D

Set Internal2

Fixed speed

“

Default Internal2

”

active. Function with selected

“

control mode

”

: 0, 1, 2 , 3

(see

“

Controller Setup

”

).

With simultaneous activation of

“

Default Internal3

”

with function

|

6D

|

,

|

5D

|

has prior-

ity).

6D

Set Internal3

Constant speed

“

Set Internal3

”

, also with selected

“

control mode

”

: 0 (see

“

Controller

Setup

”

).

13D

Switch over direction of rotation

Switch over between direction of rotation

“

RIGHT

”

=

|

CW

|

and direction of rotation

“

LEFT

”

|

CCW

|

.

When

“

switching

”

over via a digital input, the device works with the opposite direction of

rotation than the one set in Motor Setup.

If the rotary direction is reversed with an available modulation, it is initially reduced to

“

0

”

(disconnected) and subsequently increased back to the default value.

15D

Bypass temperature management (operation at max. speed)

To make the ECblue as durable as possible, the devices have active temperature

management. The modulation is reduced when internal temperature limits are ex-

ceeded.

In ventilation systems in which the fan has to continue operating at maximum speed

despite overtemperature, temperature management can be deactivated using a digital

input. At the same time, the fan is operated at maximum speed regardless of the

speci

fi

ed speed for regular operation.

The function is active at the digital input when the contact is open (in factory setting

|

D1/E1 Inverting

|

= OFF), so that the maximum fan speed is still possible even when

the line to the digital input is interrupted.

Attention!

•

This function is implemented by switching to

“

Set Intern3

”

. A setting of 100 % (=

rated speed) of

“

Set Intern3

”

is a prerequisite for operation at maximum speed.

•

The device and its internal components are no longer protected against overtemper-

ature when this function is activated (this affects the life installation instructions

ECblue).

19D

Bypass temperature management (operation with variable speed)

This function differs from 15D due to operation at variable speed. When temperature

management is switched off by a digital input, speed setting by an external signal is still

possible. The speed set in

“

Set Intern3

”

is the maximum speed at 100 % setting signal

(limitation).

OFF

No function

9.5.2

Networking via MODBUS

It is possible to network several devices with each other. The device uses the MODBUS-RTU as the

protocol for the RS-485 interface.

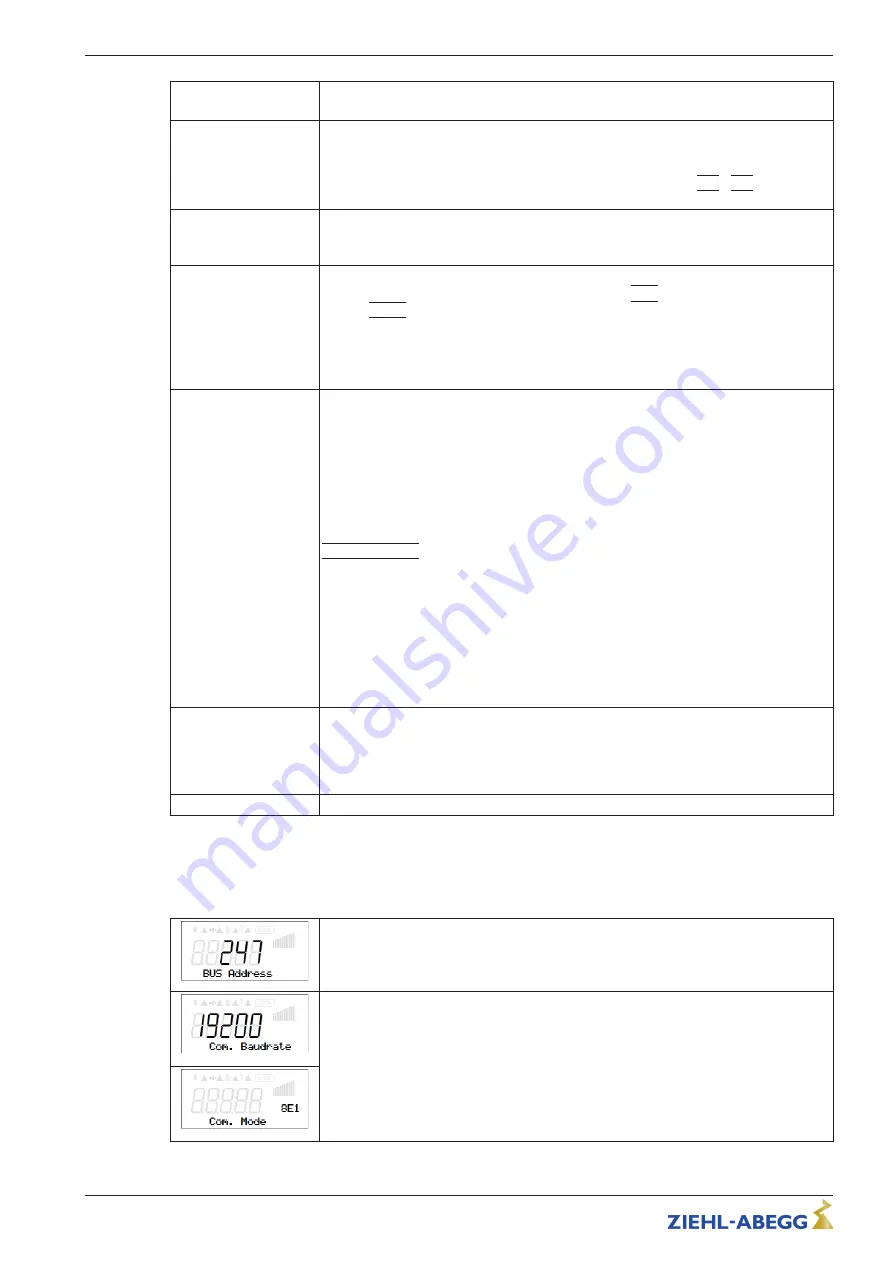

Bus Address

The device address is factory set to the highest available MODBUS address: 247.

Setting range MODBUS Address: 1 - 247.

UART Baudrate

Setting transfer rate

Valid values: 4800, 9600, 19200, 38400, 115200

Factory setting: 19200

UART Mode

Setting transfer format

Valid values: 8N1, 8O1, 8E1, 8N2

Factory setting: 8E1

Assembly instructions

ECblue BASIC-MODBUS, ECblue BASIC

Hand held terminal A-G-247NW

L-BAL-F079D-GB 2044 Index 002

Part.-No.

55/80