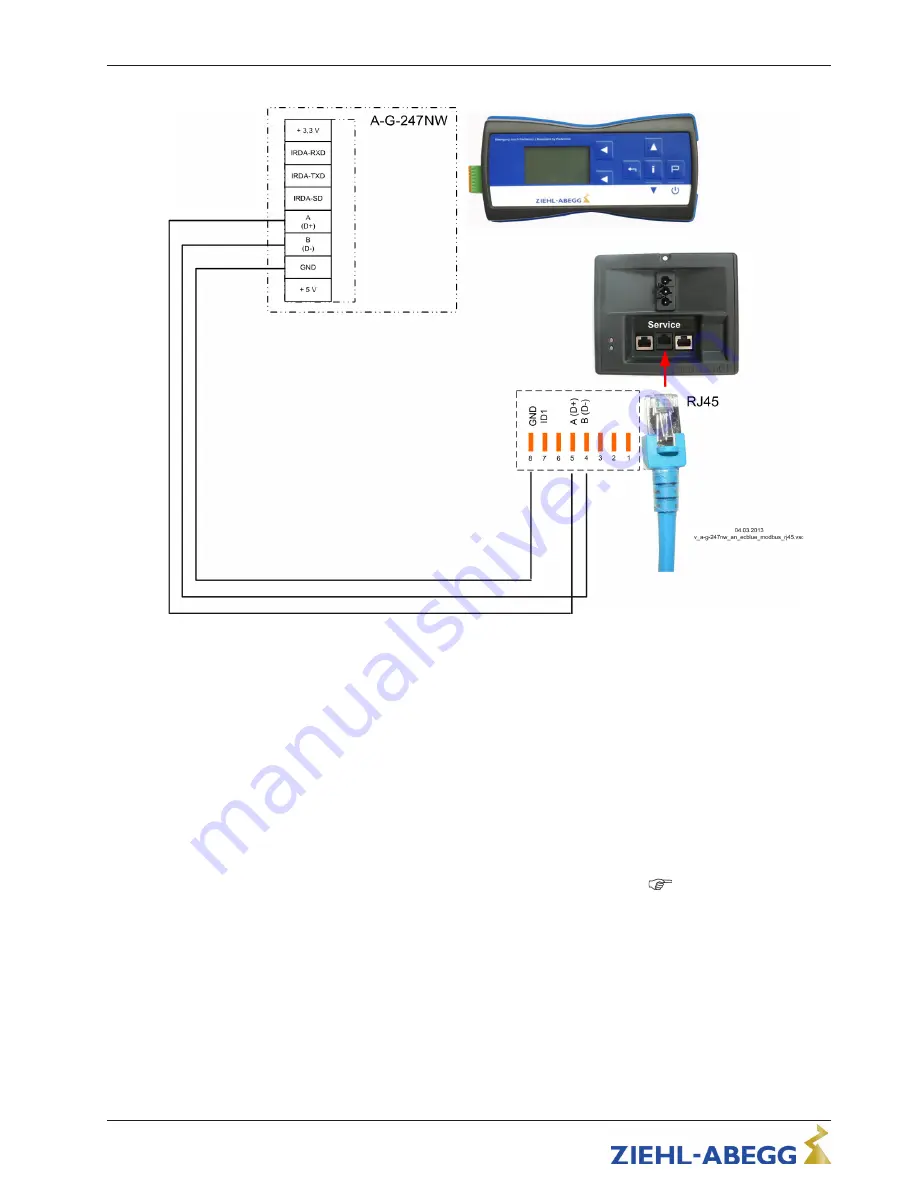

Connection with RJ45 patch cable whe using the connection box for ECblue

The connection is made at the terminals: A (D+), B (D-) und GND.

The connection is made to the connection box by the RJ45 service connection.

5.9 Communication

5.9.1 RS-485 interface for MODBUS

The device comes equipped with a RS-485 interface for networking via MODBUS.

Conntection at:

“

A (D+)

”

,

“

B (D-)

”

and

“

GND

”

.

Addressing is performed by an external terminal or a PC with the appropriate software.

Automatic addressing can be started when the connections

“

ID1

”

and

“

ID2

”

for

“

Address-

ing

”

are connected with each other additionally next to the bus connection. I. e. it is no

longer necessary to address every user manually in the network (

MODBUS network-

ing and automatic addressing).

For automatic addressing with hand held terminal type A-G-247 and digital control and

display unit NETcon type A-G-102ANE max.

63

members, with control module UNIcon

MODBUS Master max.

32

members.

Assembly instructions

ECblue MODBUS

Electrical installation

L-BAL-F041-GB 1820 Index 003

Part.-No. 00296941-GB

18/36