4.6 Mounting of centrifugal fans

4.6.1 Mounting of centrifugal fans design RE, RH, RZ

For attachment to

fi

xed motor

fl

ange use screws with property class 8.8 to EN ISO 4014

and provide with suitable screw locking.

Permissible tightening torques M

A

Thread size

M6

Property class 8.8, friction coefcient

µ

ges = 0.12

9.5 Nm

Screw penetration

≥

1.5 x d

When using screws with di

ff

erent friction values or strength classes, di

ff

erent tightening

torques may be necessary.

Mounting of centrifugal fans, RZ design

Attachment to motor fan wheel mounting according to device manufacturer's speci

fi

ca-

tions.

Information

•

Pay attention to a su

ffi

cient screw-in length in the motor

fl

ange.

•

An excess screw length of max. 3 mm is permissible.

•

Every screwing case is di

ff

erent. The tightening torque adapted to it must be

determined by the appropriate screw tests.

•

In the case of a vertical motor axis, the respective lower drain hole must be open.

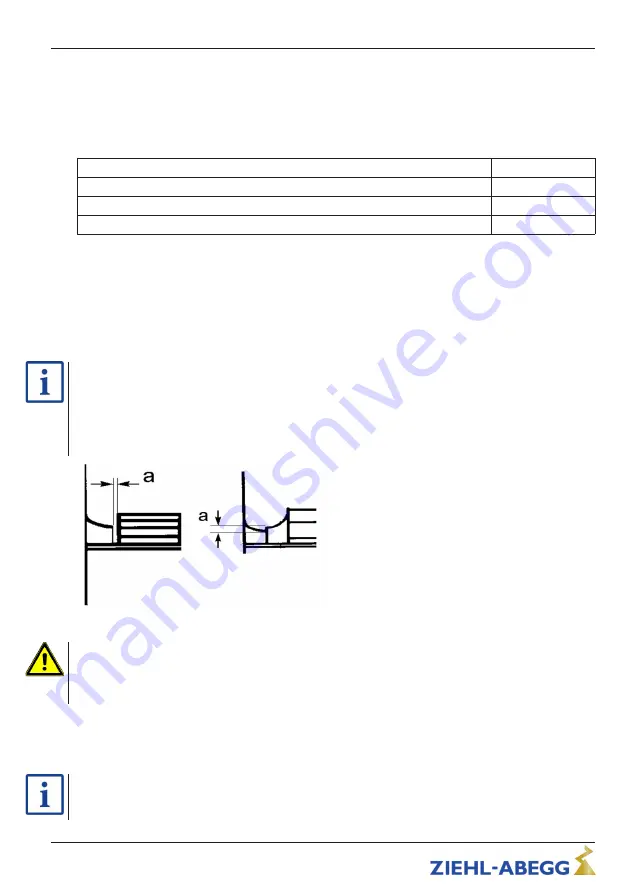

Ensure that the clearance (gap)

“

a

”

see

fi

g. be-

tween the fan impeller and the stationary

housing section is constant. Distortion due to un-

even surface may lead to fan failure.

Attention!

•

Avoid structural damage or stress with installation. Flange and mounting bracket must

be

fi

xed

fl

at on a level surface.

•

The fan must be securely mounted, with vibration dampers if necessary.

4.6.2 Mounting of centrifugal fans design RG.. / RD..

Fastening depending on housing design on

fl

ange or fastening brackets.

Information

An additional bracket is required for fastening to the

fl

ange. This is available as an

accessory.

Assembly instructions

ECblue

Mounting

L-BAL-F056-GB 2022/45 Index 005

Part.-No. 00700562-GB

15/44