7.2 Cleaning

Danger due to electric current

•

Voltage supply for motor must be interrupted and secured against restoration!

•

Do not use any aggressive cleaning agents when cleaning.

•

Make sure that no water gets into the inside of the motor and electronics.

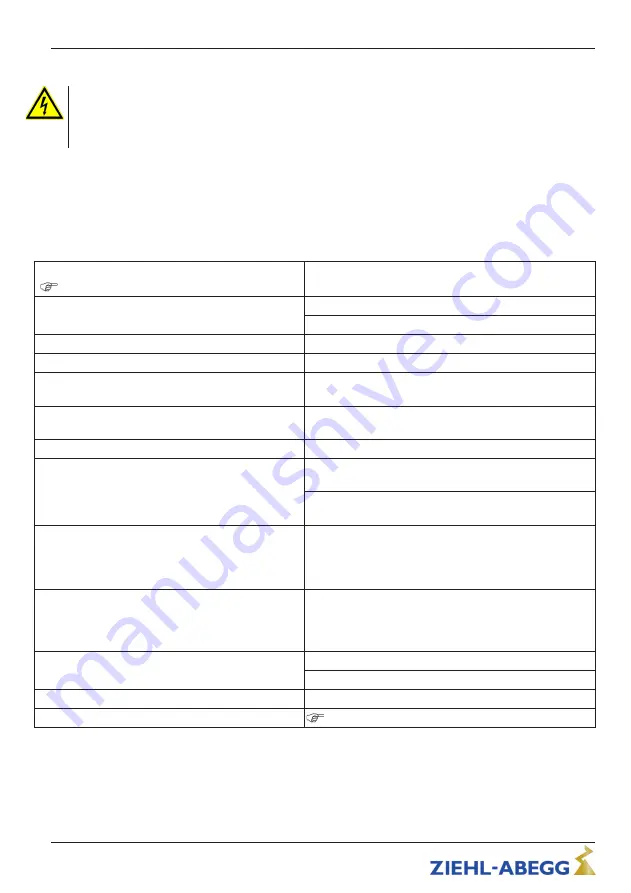

8 Enclosure

8.1 Technical data

Line voltage*

(

Rating plate)

1 ~ 200...264 V, 50/60 Hz

1 ~ 100...134 V, 50/60 Hz

Power consumption (P1)

Version with one speed: max 18 W

Version with three speeds: max. 34 W

Maximal line fuse

4 A

Max. load limit integral of cut-in current approx.

0.118 A

2

s

Permissible minimum and maximum ambient tem-

perature for operation

-40...+50

°

C

Permissible temperature range for storage and

transport

-40...+80

°

C

Permissible rel. humidity

85 % no condensation

Electromagnetic compatibility for the standard volt-

age 230 / 400 V according to IEC 60038

Interference emission according to EN 55014-1 (do-

mestic household applications)

Interference immunity according to EN 61000-4-4 (in-

dustrial applications)

Harmonics current

In accordance with EN 61000-3-2

Please ask manufacturer for the individual harmonic

oscillation levels of the current as a percentage of the

fundamental oscillation of the rated current.

Ball bearings grease service-life (F

10h

)

The device is designed with a life time for the bearings

and a bearings service-life of at least 40.000 h when S

operated at full power in the maximum permissible

ambient-temperature environment.

Connection

Version with one speed: H03VV-F 2 x 0.5 mm

2

Version with three speeds: H03VV-F 3 x 0.5 mm

2

Protection class of motor according to EN 60529

IP55

Weight

rating plate

Assembly instructions

FE2owlet-ECQ

Enclosure

L-BAL-F062-GB 2022/20 Index 004

Part.-No. 00702389-GB

18/24