4.5.2

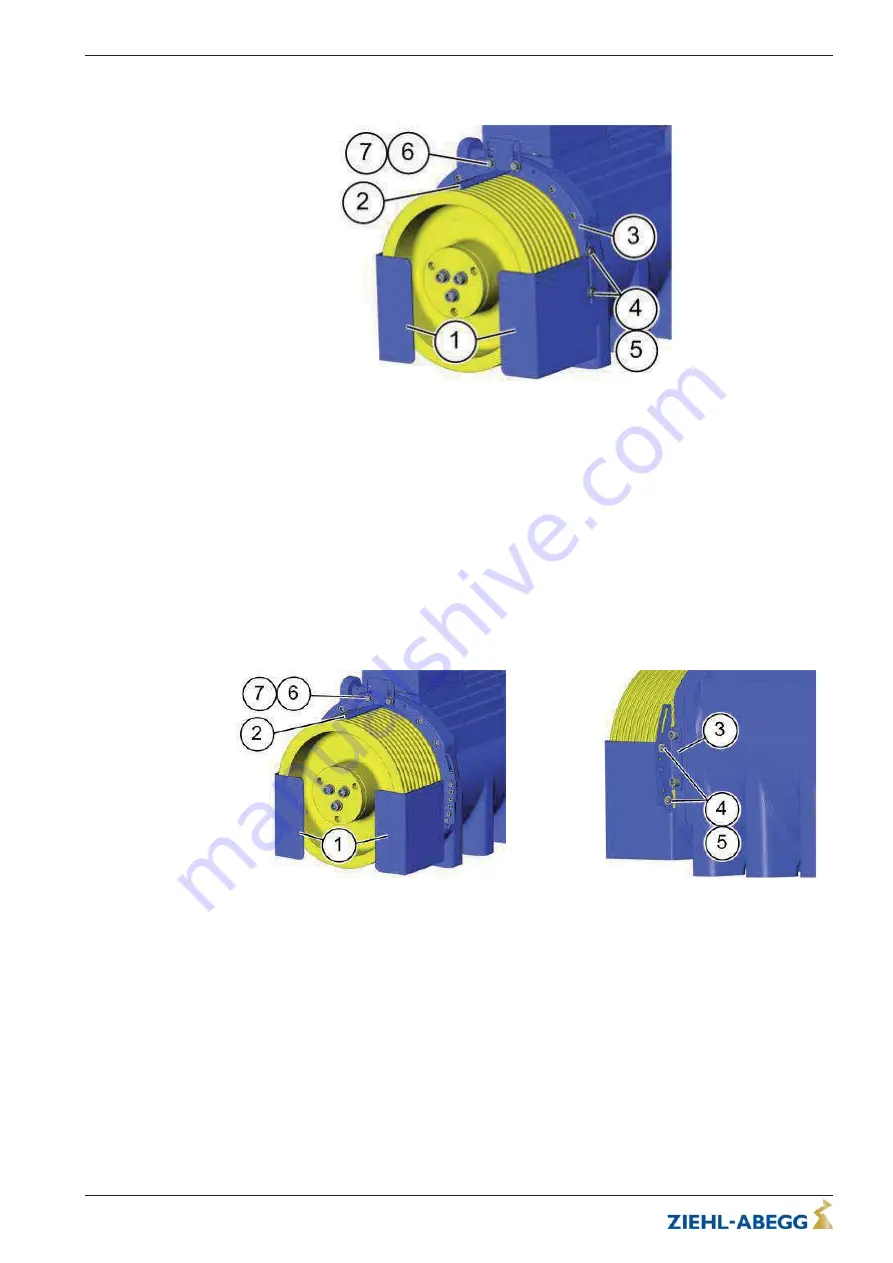

Rope guard fastening in the case of a traction sheave diameter of 400 mm

For wrap angle 180

°

.

Rope guard in the case of a traction sheave diameter of 400 mm

"

"

The rope guard (1) is attached to the bearing plate (3) with two socket cap screws M12 x 25 - 8.8 (4)

and washers (5).

"

"

The elongated hole in the rope guard (1) enables the required distance to the ropes to be set at the

socket cap screws M12 x 25 - 8.8 (4).

Tightening torque M12 - 8.8: 79 Nm

"

"

The third rope retainer (2) is fastened with two hexagon head screws M12 x 25 - 8.8 (6) and

washers (7).

"

"

Through the elongated holes in the 3. rope retainer (2) enables the required distance to the ropes to

be set at the hexagon nuts M12 (6).

Tightening torque M12 - 8.8: 79 Nm

4.5.3

Rope guard fastening in the case of a traction sheave diameter of 400 mm

Adjustability on both sides + 5

°

/- 30

°

. Normal wrap angles 30

°

- 185

°

.

Rope guard in the case of a traction sheave diameter of

400 mm

"

"

The rope guard (1) is fastened in each case with two safty screws M6 x 12 - 8.8 (4) and washers (5)

to the relevant

fi

xing plate (3).

"

"

Through the elongated holes in the

fi

xing plate (3) enables the required distance to the ropes to be

set at the safety screws M6 x 12 - 8.8 (4).

Tightening torque M6 - 8.8: 9,5 Nm

"

"

The third rope retainer (2) is fastened with two hexagon head screws M12 x 25 - 8.8 (6) and

washers (7).

"

"

Through the elongated holes in the 3. rope retainer (2) enables the required distance to the ropes to

be set at the hexagon nuts M12 (6).

Tightening torque M12 - 8.8: 79 Nm

Translation of the original operating instructions

ZAtop SM250.45B

Mechanical installation

A-TBA17_04-GB 2023/28 Index 004 Part.-No. 01013409-GB (EU-BD 760/1)

14/84