U-EK230E

L-BAL-E185-GB 2023/10 Index 005

11660-0711-03

9/12

•

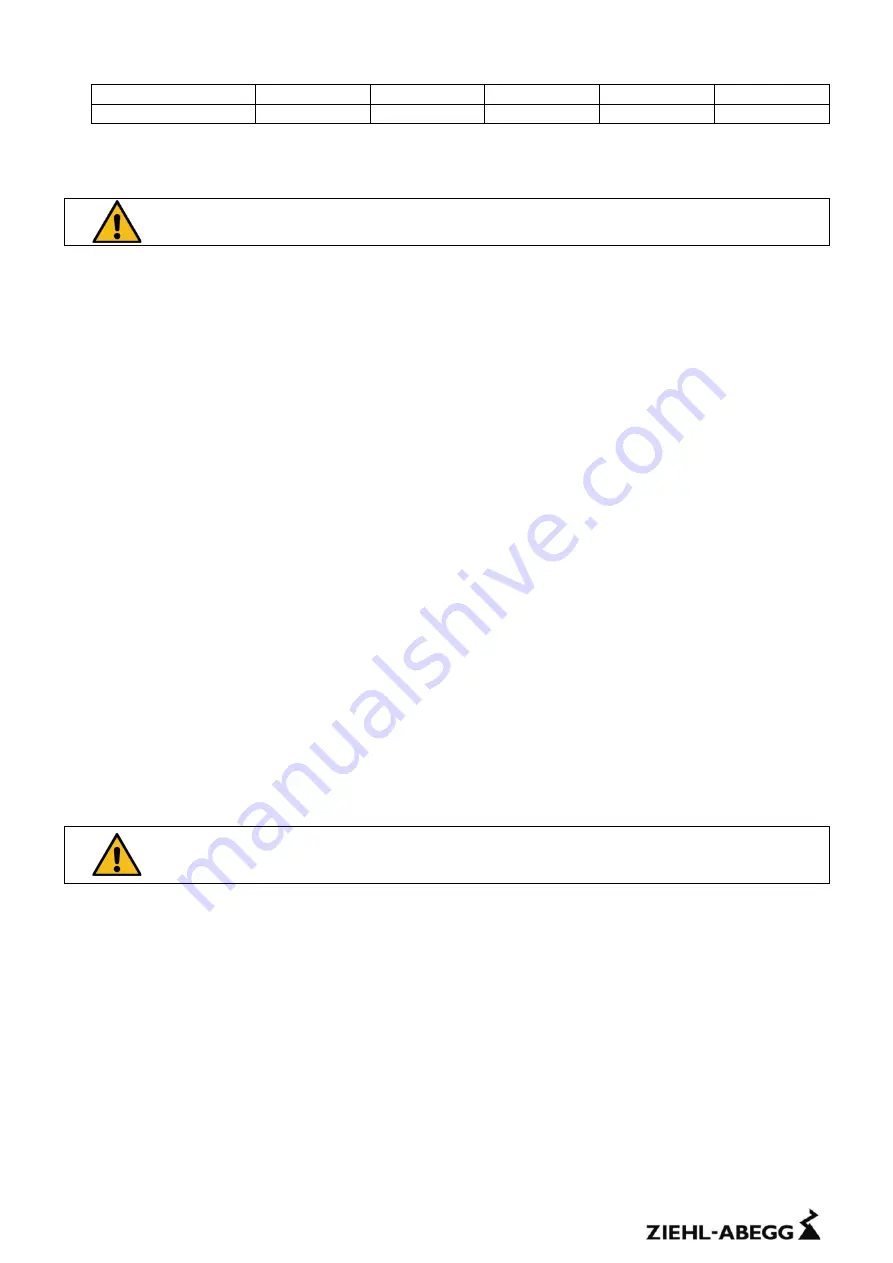

Maximum permissible length for thermistor circuit lines:

Wire length

2 x 1000 m

2 x 800 m

2 x 500 m

2 x 300 m

2 x 250 m

Wire cross section

2.5 mm

2

1.5 mm

2

1.0 mm

2

0.75 mm

2

0.5 mm

2

•

With commissioning and after modification of the plant the thermistor resistance must be checked

with a suitable measuring instrument. With a resistance < 50 Ω the thermistor circuit is to be

examined for short-circuit.

Attention!

Check thermistors only with measuring voltages of < 2.5 V.

15.8 Safe separation

•

Line circuits (A1, A2) and (11, 12, 14) have a safe separation to low-voltage electric circuits (T1, T2)

and (Y1, Y2).

15.9 Stop function

•

A stop function triggered by the device must transfer the machine as fast as possible into a safe

state. The stop function must have top priority.

•

In case of failure the device switches off the contactor / circuit breaker and prevents an overheating

of the isolation system and / or the surface temperature. The protective function of the device is only

guaranteed if the wiring is done directly in the control circuit of the motor in accordance with the

connection diagram. The contacts must be protected, to prevent welding.

15.10 Start and restart

•

Only if no dangerous condition is present, a reset is allowed. A device with bridged terminals Y1, Y2

(auto reset) switches back on after the thermistors cooled down. This function must not be used in

applications where an automatic reset could cause personal injuries or damage to property

15.11 Manual reset

•

When the device triggers a stop instruction, it must be maintained until the manual reset mechanism

is operated and safe conditions for a renewed start are given. The manual reset must be only

possible if all safety functions and protection devices are effective.

•

The stop instruction remains, until a reset is made by pressing the push-

button „Reset“. A start-up is

only possible, if no case of failure occurs and the motor is cooled down to a sufficient value of

temperature.

•

The device switches on automatically with return of supply voltage. The user must guarantee by

external interlock (see connection diagram) that the supervised machine does not start again

independently.

Attention!

Safety circuits according to EN 60204 / EN 62061. The devices must not be used

alone for functions, where an automatic restart must be prevented.

16

Proof testing of the safety functions

•

The safety function must be tested at regular intervals. It is recommended to carry out the proof-test

once a year. Depending on the zone risk, tests should be conducted more frequently. A fault is

recognized by the safety test. A fault between safety tests could cause loss of protection.

The following must be tested additionally to recurring examinations with maintenance services:

•

The safety function must be tested by interrupting the thermistor circuit wire at terminals T1, T2.

•

The short circuit monitoring function must be tested by bridging the thermistor circuit wires at

terminals T1, T2.

•

The safety function must be tested by changing the resistance from

50…1500 Ohm to 4000 Ohm at

terminals T1, T2.

•

The function of the electronic interlock must be tested additionally.

•

If an error is detected no restart must be induced until the error is cleared.