5 Electrical installation

5.1

Safety precautions

Work on electric components may only be carried out by trained electricians or by persons instructed

in electricity under the supervision of an electrician in accordance with electrical engineering regula-

tions.

A second person must always be present when working on energized parts or lines who disconnects

in case of emergency.

Electrical equipment must be checked regularly: Loose connections are to be re-tightened and

damaged cables must be replaced immediately.

Always keep switch cabinets and all electrical supply facilities locked. Access is only allowed for

authorized persons using a key or special tool.

Never clean electrical equipment with water or similar liquids.

5.2

EMC Directive

Compliance with the EMC directive 2014/30/EU only applies to this product if frequency inverters

tested and recommended by ZIEHL-ABEGG SE are used and they are installed in line with the

associated operating instructions and are EMC-compatible. If this product is improperly integrated into

a system or is combined and operated with non-recommended components, the manufacturer or

operator of the complete system is solely responsible for compliance with the EMC

directive 2014/30/EU.

5.3

motor

CAUTION!

"

"

The motor cable for the elevator machine is available as an option.

"

"

The elevator machine may not be connected to the supply voltage without a frequency

inverter.

5.3.1

Cable cross section

The cable cross-section must be speci

fi

ed dependent on the motor current and the ambient conditions

(e.g. temperature, wiring method) in accordance with DIN VDE 0298-4.

5.3.2

Type of cable

Always use shielded cables for the motor connection. Both rigid and

fl

exible cables can be used.

5.3.3

Cable length

The maximum cable length is 25 m. With a motor line

> 25 m

compliance with DIN EN 12015 (Electro-

magnetic Compatibility - Interference emissions) and DIN EN 12016 (Electromagnetic Compatibility -

Interference immunity) can no longer be guaranteed.

5.3.4

Mechanical connection conditions

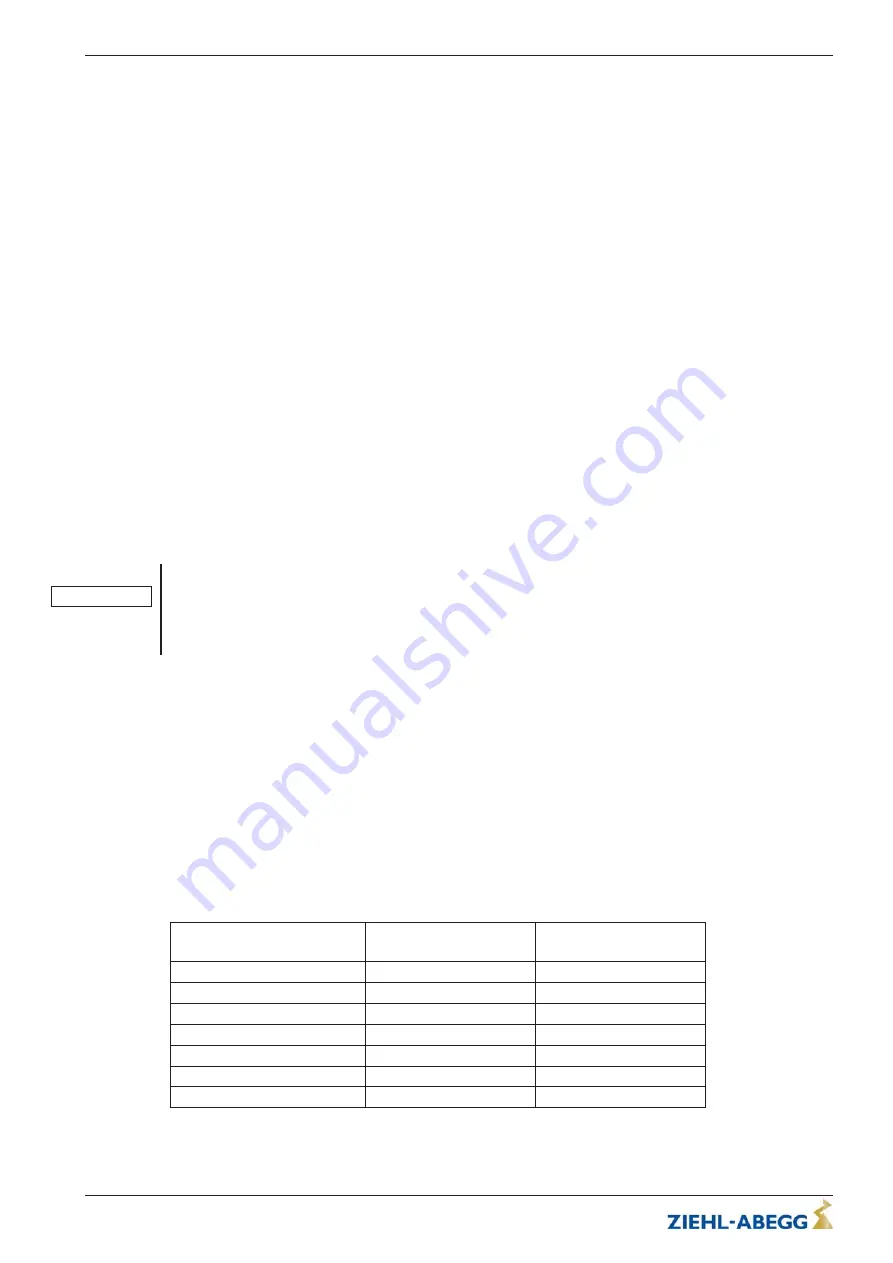

Rated motor current

[A]

Thread size

Terminal board

Thread size

Cable gland

up to 20

M8

M25

> 20 - 35

M8

M32

> 35 - 63

M8

M40

> 63 - 80

M8

M50

> 80 - 100

M10

M50

> 100 - 125

M10

M63

> 125

M12

M63

Table 5-3-4

Original operating instructions

ZAtop

–

model series SM315.100A

Electrical installation

A-TBA22_02-GB 2022/50 Index 002 Part.-No. 01013486-GB (EU-BD 1075)

16/76