INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 11/39

3.

Transport, installation and storage of Z-2323

Transport

Before transporting the machine, disconnect the compressed air supply. The machine can be

transported in one block and does not require disassembly. For transport, the height of the Filling

head should be set at the lowest possible level (using the height adjustment mechanism of the

stand).

Transport of the machine must be performed in accordance with safety

regulations!

Installation

The weight of the on-table model is approximately 114 kg. The Manufacturer suggests placing the

device on a stable table, so as to allow the operator to work in standing or seating position

depending on the table height.

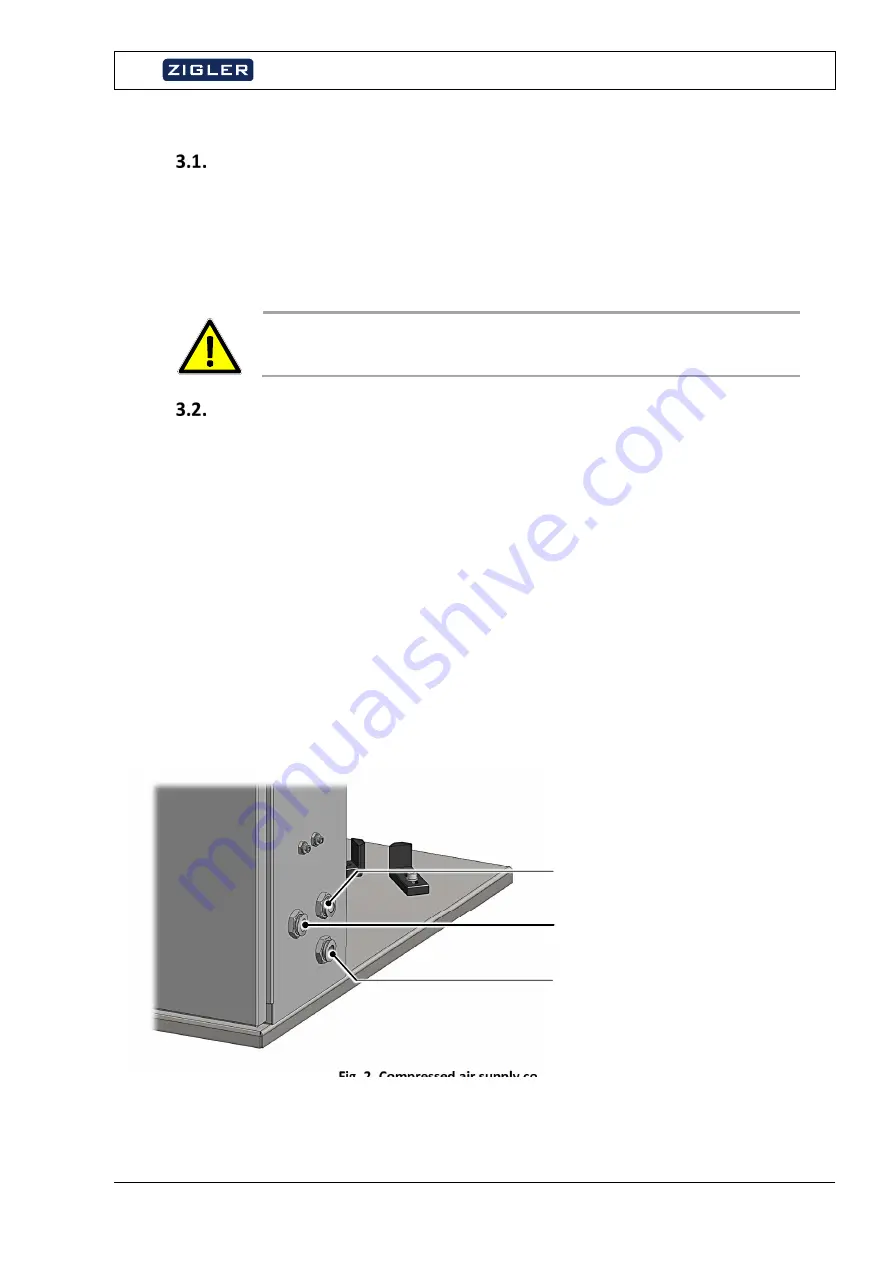

After the initial placing the machine on destination site, provide compressed air supply to the

connection at the right side panel of the cabinet [Fig. 2, pos. 1]. Proper connection requires

providing of a pneumatic tube of ext. diameter ø12 mm. Furthermore, due to the use of oiled

compressed air in machine, all exhausts of air discharged from valves were collected in one circuit

in order to avoid direct emission into working space of the machine. The circuit ends with a

pneumatic connection plug, installed close to the air supply connection [Fig. 2]. It is necessary to

provide a duct from connection socket (by means of pneumatic tube of ø12 mm in ext. diameter)

to the point where the emissions of oiled air does not create a threat to the production purity.

1.

Air supply connection

2.

Control cabinet exhaust

outlet

3.

Filling module exhaust outlet

Fig. 2. Compressed air supply connection and

2

1

3

Summary of Contents for Z-2323

Page 42: ...PNEUMATIC DIAGRAMS ...