INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 22/39

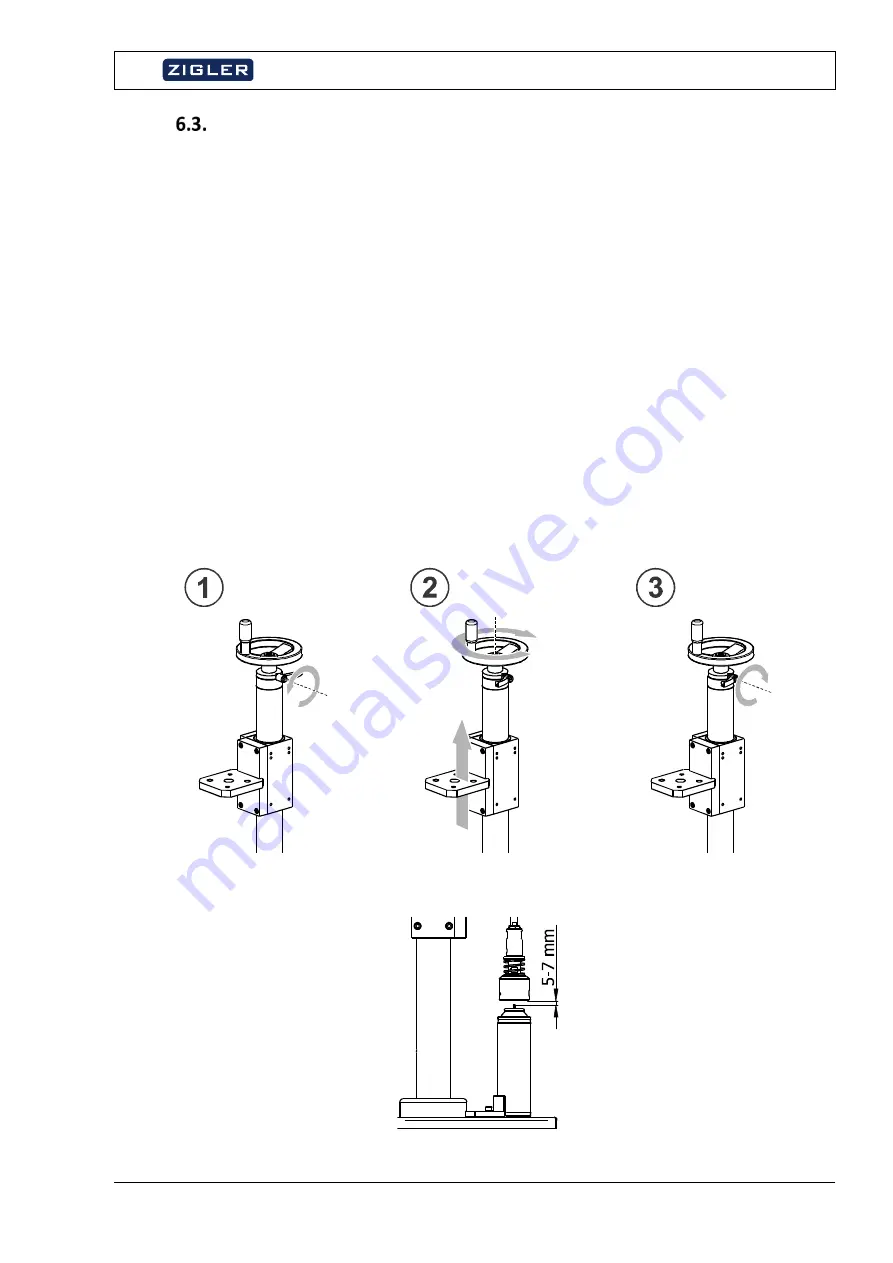

Setting the height of filling and cleaning head

Crimped containers may be of 65

÷

320 mm height. The height adjustment should always be

performed on initial state of the machine – when the compressed air supply is enabled and working

heads are in upper position. Height adjustment should be carried out with respect to the filling

head. To adjust the height:

1.

Place empty aerosol container with crimped valve under Filling head. Loosen the blockade

of the regulation hand-wheel located on the side, in upper part of the stand - Fig. 12, pos. 1.

2.

Raise the Filling head by turning the crank clockwise [Fig. 12, pos. 1] to such a height that

the gap between the aerosol valve stem (tube) and the Filling head is 5-7 mm - Fig. 13.

3.

Using a footswitch fill one container. If the lowering actuator returns instantly to its initial

upper position without filling the container - the gap is too large. Reduce the height and try

filling another container (never fill the same container more than once to avoid its

bursting). In case of necessity, repeat these actions until the Filling is performed correctly.

4.

After the correct height is set, tighten the blockade of adjustment wheel on support stand

- Fig. 12, pos. 3.

Fig. 12. Adjusting the height of filling head

Fig. 13. Correct height of crimping head

Summary of Contents for Z-2323

Page 42: ...PNEUMATIC DIAGRAMS ...