INSTRUCTION MANUAL

Semi-automatic BOV Filling Machine Z-2323

A0310.02.2323.905.1.EN

Page 26/39

7.

Maintenance of Z-2323

Conditions of the functional reliability and life of pneumatic control

systems

Work safety and life of the pneumatic system to a substantial degree depend on the preparation of

compressed air. Polluting compressed air with e.g. scale, rust, dust, as well as liquid ingredients in

the air such as condensed steam, may cause a lot of damage to pneumatic devices. Such pollutants

contribute to rubbing smooth surfaces and sealing elements. It makes it difficult for pneumatic

elements to function properly and shortens their life. Starting and switching off the compressor

causes pressure fluctuations, which exert an unfavorable influence on the functioning of the

system. In order to eliminate these influences, every pneumatic control system must be equipped

with devices preparing compressed air.

Air must always be so clean that it could not cause any disturbances or damage. Because every filter

causes resistance to flow as well, compressed air should be, from the economy point of view, always

only as clean as it is necessary. The quality of compressed air is described with accuracy classes

according to the ISO 8573-1 norm.

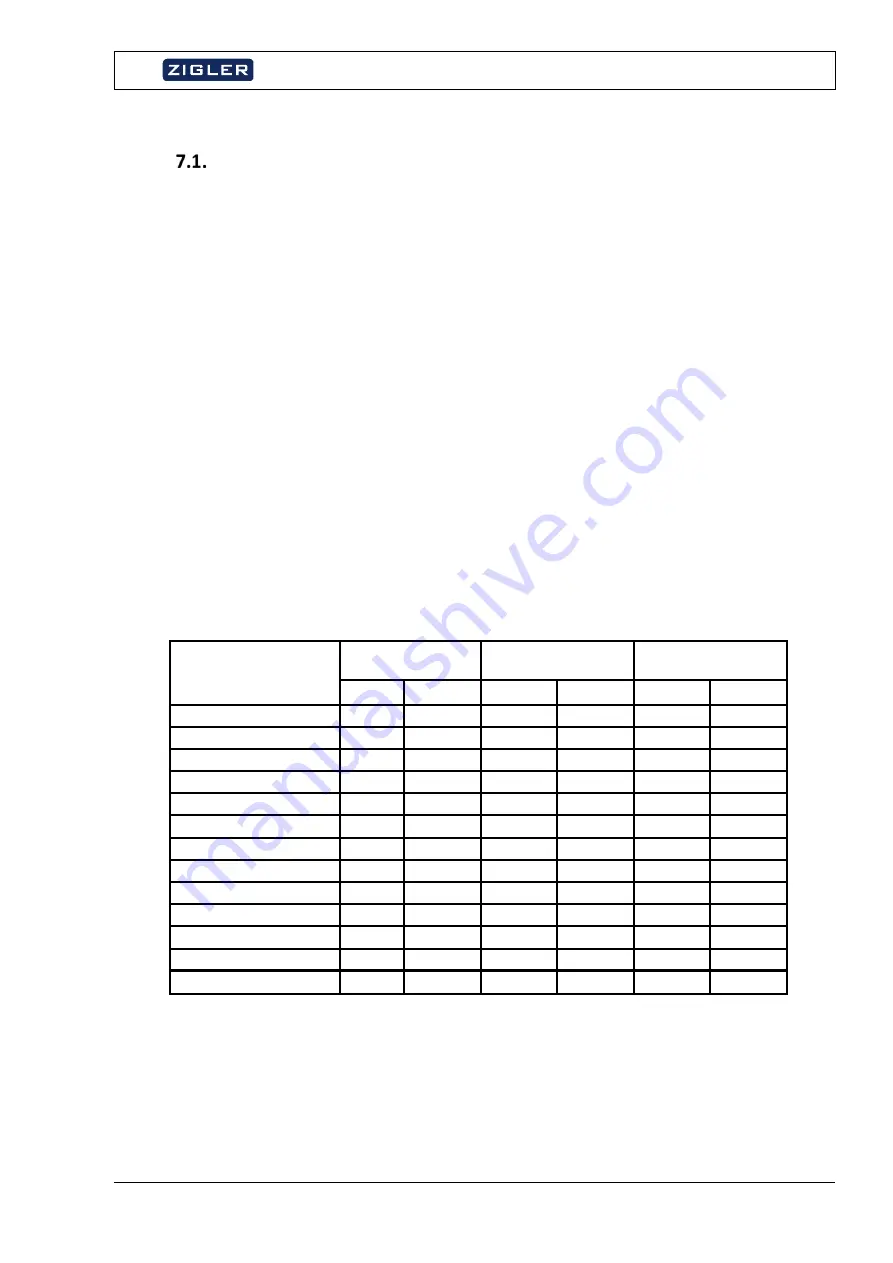

Tab. 2. Class of air quality requirements for specific applications

APPLICATION

SOLID PARTICLES

PRESSURE

SATURATION POINT

OIL CONTENT

Class

(

µ

m)

Class

(

0

C)

Class

(mg/m

3

)

Mining industry

5

40

7

-

5

25

Cleaning

5

40

6

+10

4

5

Welding machines

5

40

6

+10

5

25

Tools

5

40

4

+3

5

25

Pneumatic operators

5

40

4

+3

5

25

Pneumatic valves

3

÷

5

5

÷

40

4

+3

5

25

Packaging machines

5

40

4

+3

3

1

Precision limiters

3

5

4

+3

3

1

Air for measurements

2

1

4

+3

3

1

Stored air

2

1

3

-20

3

1

Sensorics

2

1

2

÷

3

-40

÷

-20

2

0,1

Food products

2

1

4

+3

1

0,01

Photography processing

1

0,01

÷

0,1

2

-40

1

0,01

Summary of Contents for Z-2323

Page 42: ...PNEUMATIC DIAGRAMS ...