ZIMM Screw Jack

7 Operation

and maintenance

2015-01

Version 1.2

29

7.2.4

Greasing the ball screw drive KGT spindle

Procedure

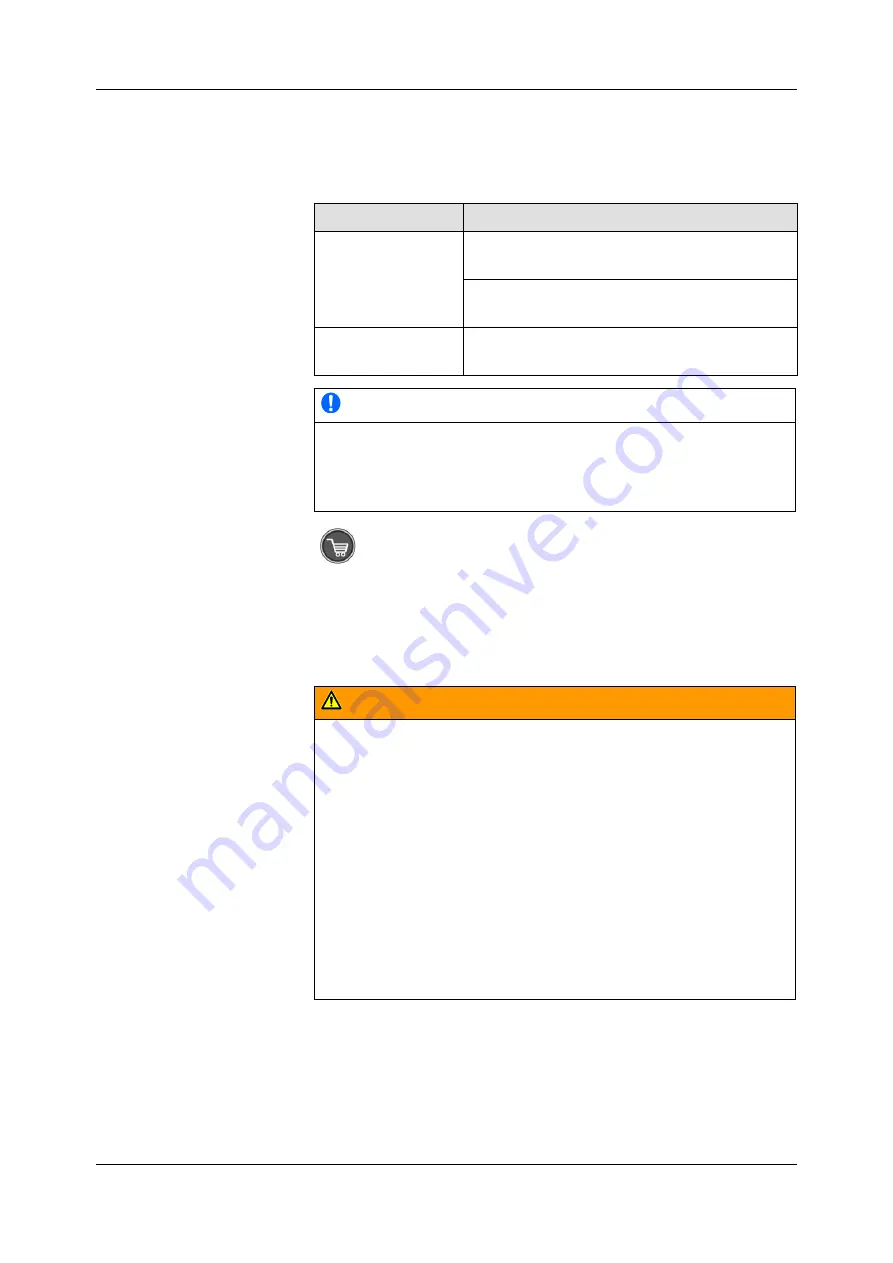

Interval

Regreasing the

spindle

If heavily loaded

after 100 hours (effective)

If normally or lightly loaded:

after 300 hours (effective)

Clean the spindle

and regrease it

If the spindle is dirty

NOTE

The interval for greasing depends on the application.

Monitor the state of the grease, and specify the interval

accordingly.

Standard grease for ball screw drive KGT

Part no.: Castrol Tribol GR 4747/220-2 HT, 400 ml cartridge

Quantity (indicative value):

•

1 ml per 1 cm spindle diameter.

When changing the grease: The spindle must be clean.

WARNING

Jack travel in the lifting travel zone!

Death, serious injury or crush hazard.

When using a grease gun for greasing, make sure that sufficient

freedom of movement is available for the entire jack travel.

If the freedom of movement is insufficient

– Switch off the entire system and secure it against switching on

again.

– Performing greasing when installed.

– For greasing when installed, move the nut successively to

several positions, so that the spindle is evenly greased.

Intervals

Grease

Preconditions