ZIMM Actuator

6 Installation

22

Version 0.6

2023

6.6

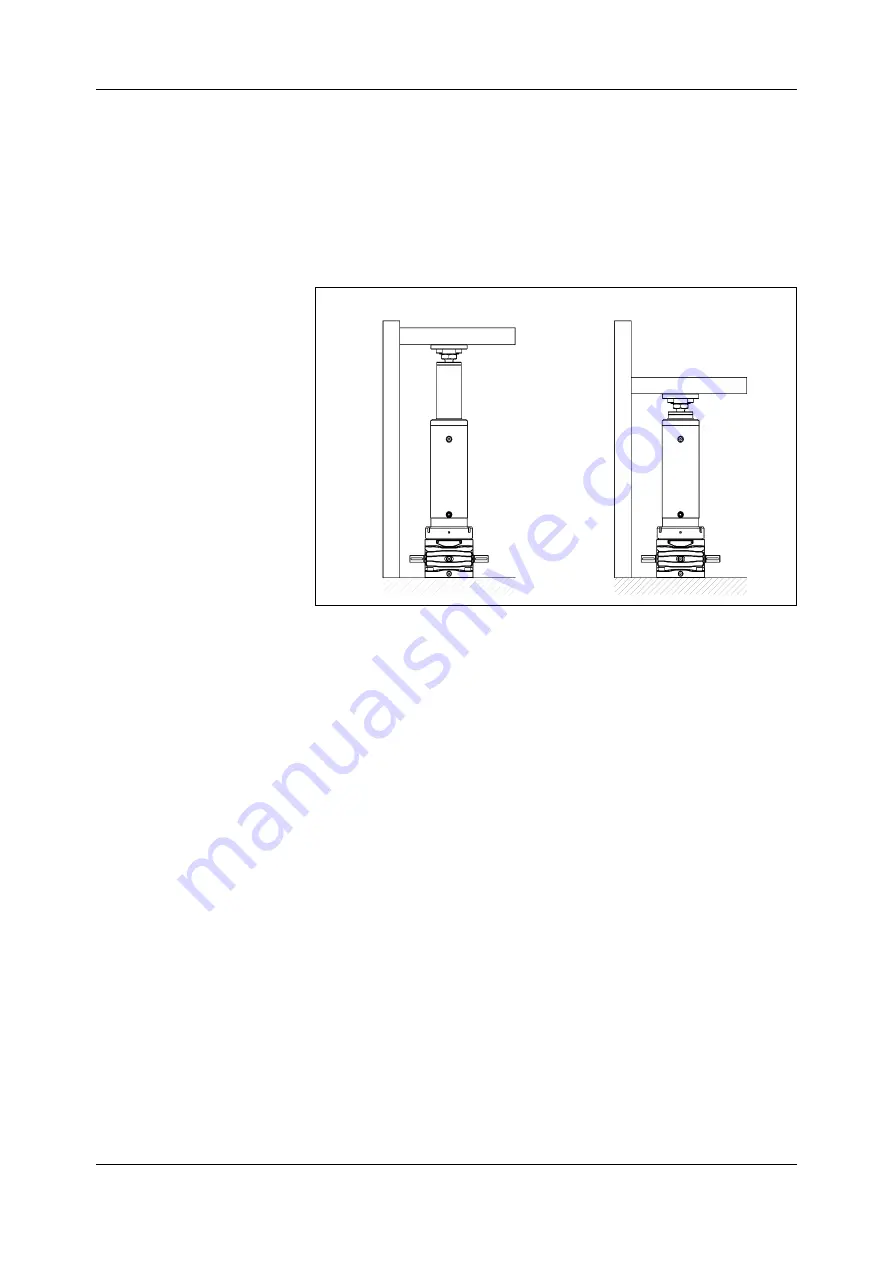

Correcting the alignment

If necessary, the alignment can be corrected without much trouble.

Spindle and anti-rotation lock lubricated (for more information

see section “7.2 Lubrication”, page 25)

Fig. 18: Correctly aligned ZIMM Actuator

1.

Loosen the fastening screws on the gearbox housing and on the head.

2.

Fully retract the jack (1).

3.

Tighten the securing bolts.

4.

Repeat the trial run (see section 6.5, page 20).

1

Summary of Contents for ZA-25

Page 33: ......