40

INFORMATION

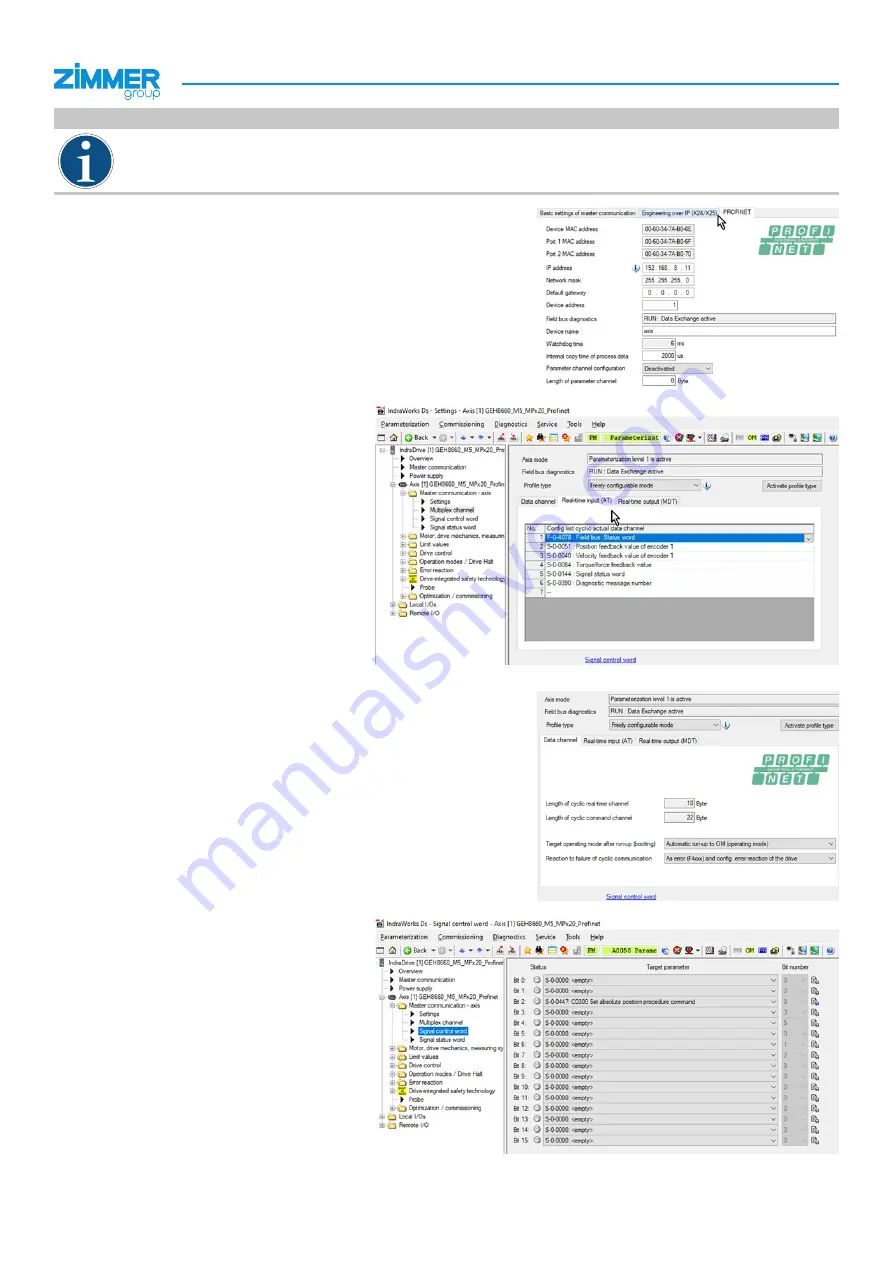

The Profinet interface needs its own network address.

A network connection therefore has two separate IP addresses that can be addressed in different ways.

►

Click the

PROFINET

tab.

►

Enter the IP address of the Profinet interface on the Profinet tab.

►

In the navigation pane, click

Axis [1]

.

►

Click

Master Communication Axis [1]

.

►

Click

Settings

.

►

Click the

Process Data In (AT)

tab.

►

In the drop-down menus of the fields, select

the desired files for communication between

the PLC and the drive control unit.

Ö

The actual value data channel is comprised

of the following parameters on the

Process

Data In (AT)

tab.

Ö

The target value data channel is comprised

of the following parameters on the

Process

Data Out (MDT)

tab.

For successful communication between the PLC and the drive control

unit, it is important that the data length of the process input map and

process output map be configured correctly.

In this example project, 18-byte inputs (actual value data channel) and

22-byte outputs (target value data channel) are needed. This data length

is generated automatically from the previously configured settings.

The

IndraWorks Ds

software specifies the data length in bytes, the

hardware configuration from Siemens specifies the data length in words.

►

Click the

Data Channel

tab.

►

In the navigation pane, click

Axis [1]

.

►

Click

Master Communication Axis [1]

.

►

Click

Signal Control Word

.

►

In the drop-down menus, select the target

parameters for the individual bits.

Ö

The switching enables communication

between the PLC and the drive control unit.

Zimmer GmbH • Im Salmenkopf 5 •

77866 Rheinau, Germany •

+49 7844 9138 0 • www.zimmer-group.com

INSTALLATION AND OPERATING INSTRUCTIONS:

GEH8000

DDOC00262 / e

EN / 2023-03-06