INSTALLATION AND OPERATING INSTRUCTIONS:

GPH8000

INSTALLATION AND OPERATING INSTRUCTIONS:

GPH8000

EN / 2021-10-19

EN / 2021-10-19

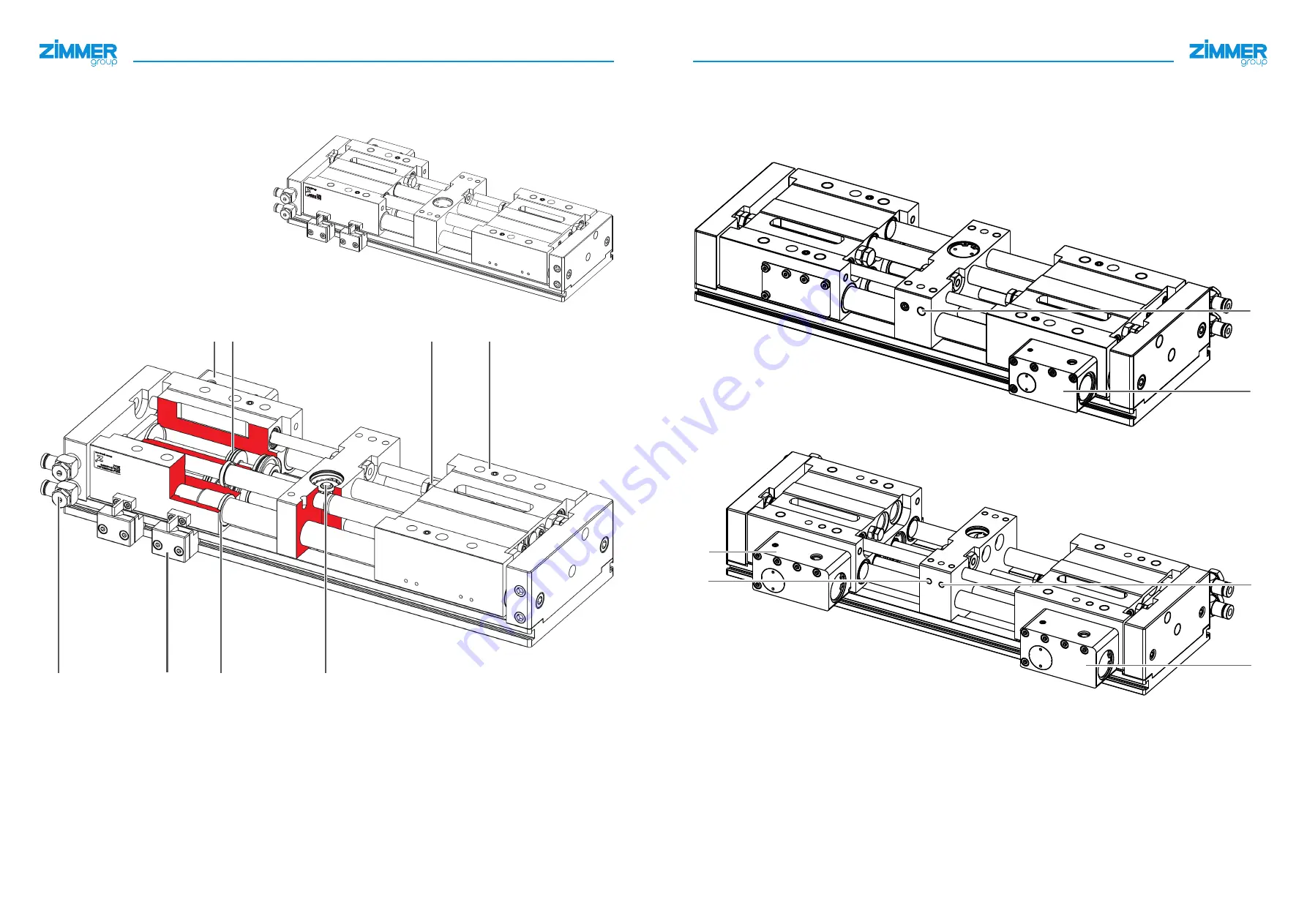

6 Functional description

The product has two pneumatic pistons that are vented on both sides. Alternating ventilation sets the gripper jaws in

motion. The power supply can be made one-way or two-way.

1

Clamping element

2

Drive

3

Stroke limitation

4

Gripper jaw

5

Power supply

6

Terminal block

7

Round guide

8

Synchronization

2

1

3

4

5

6

7

8

Clamping elements are used to secure the gripper jaws. This securing element is transfered to both gripper jaws by the

synchronization in the CL-00 variant. In the CL-30 variant, two clamping elements are installed. These can be actuated

independently of each other. There are no clamping elements installed in the N-00 variant. The clamping elements are

pre-tensioned by a spring in order to secure the jaw position in case of a drop in pressure. Applying pressure releases the

clamping element.

CL-00 variant

9

bl

CL-30 variant

bn

9

bm

bl

9

Open clamping element 1

bm

Clamping element 2 (CL-30 variant)

bl

Clamping element 1

bn

Open clamping element 2 (CL-30

variant)

Zimmer GmbH • Im Salmenkopf 5 •

77866 Rheinau, Germany •

+49 7844 9138 0 • www.zimmer-group.com

Zimmer GmbH • Im Salmenkopf 5 •

77866 Rheinau, Germany •

+49 7844 9138 0 • www.zimmer-group.com

DDOC00289 / b

DDOC00289 / b

6

7