INSTALLATION AND OPERATING INSTRUCTIONS:

Motor spindle, HF125-002 series

Zimmer GmbH

•

Im Salmenkopf 5

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

+49 7844 9138 80

•

www.zimmer-group.com

16

EN / 2020-11-25

DDOC00743 / -

9.4 Installing the power supply

CAUTION:

Malfunction due to improper power supply installation

Installing the power supply correctly ensures that the product will function properly.

Ö

Always install flexible power supply lines.

NOTICE:

Function of the product is ensured

The function of the product is ensured if:

•

The power supply lines have adequate dimensions

•

The power supply lines are used that are as short as possible and shielded throughout their entire length

If the power supply lines do not have adequate dimensions, the product might have an insufficient supply.

Ö

Fault or damage to the product.

INFORMATION:

The bending radius of the power supply lines must not fall below the minimum value!

Cables that are hanging freely must be affixed!

Ö

Excessive movement stress or crushing must be avoided.

Refer to the technical datasheet for the wiring diagrams, plug coding and fluid connections.

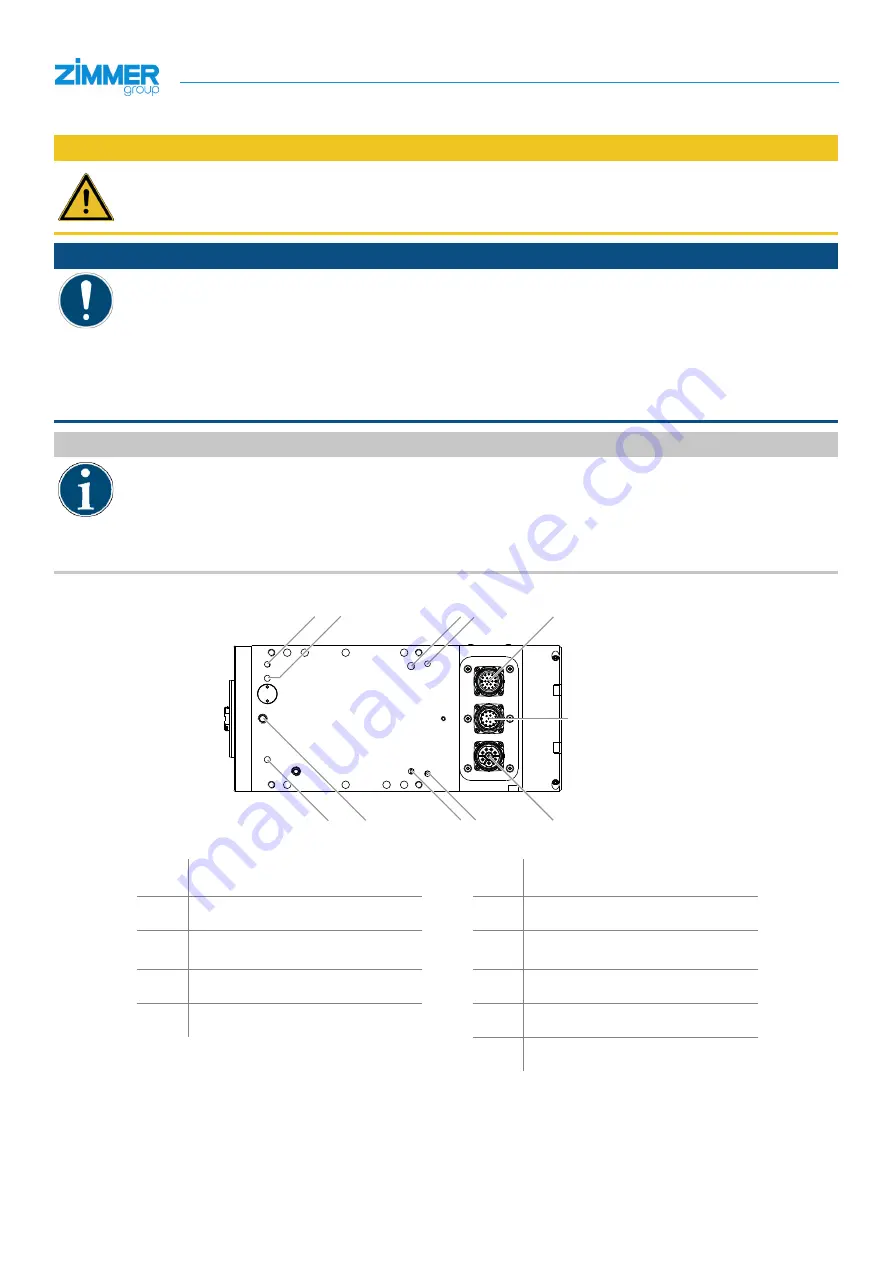

E A

XG2

XD1

KR

F

SPL

H2

H1 H3

XG3 (optional)

H1

Controllable connection

XD1

Power connection and signal

connection

H2

Controllable connection

XG2 Signal connection

H3

Controllable connection

XG3 Position sensor and speed sensor

(optional)

SPL

Purging air

F

Cooling system, recirculation

KR

Cone cleaning

E

Cooling system, feed

A

Release the tool