INSTALLATION AND OPERATING INSTRUCTIONS:

Motor spindle, HF125-002 series

Zimmer GmbH

•

Im Salmenkopf 5

•

77866 Rheinau, Germany

•

+49 7844 9138 0

•

+49 7844 9138 80

•

www.zimmer-group.com

24

EN / 2020-11-25

DDOC00743 / -

10.3 Tool interface (setting dimensions/clamping force)

DANGER:

Risk of death due to ejection of the tool holder during operation of the product!

Ö

In the event that the clamping system of the product was incorrectly set, a loss/ejection of the tool cannot be

ruled out during operation (rotation).

Ö

Injury to personnel or material damage may result.

Risk of death due to insufficient clamping force of the tool holder of the product!

Ö

If the clamping force of the product is insufficient („Visual inspection of the product“), a loss/ejection of the

tool cannot be ruled out during operation (rotation).

Ö

Injury to personnel or material damage may result.

NOTICE:

Do not use compressed air to clean the tool interface!

Do not use any cleaning agents that contain solvents!

Verify the setting dimensions at the tool interface.

When doing so, the following work steps must be observed:

►

Switch the machine to "setup mode."

►

Secure the tool to prevent it from falling.

►

Actuate the loosening unit using the machine control system to release the tool.

►

Remove the tool or unit from the product in the axial direction.

►

Clean the product using a clean, soft rag.

• Plane face of the tool holder

•

Gap between the quick-change tool adapter and the surface of the taper

►

To extend the clamping set, actuate the loosening unit by using the machine control system

Ö

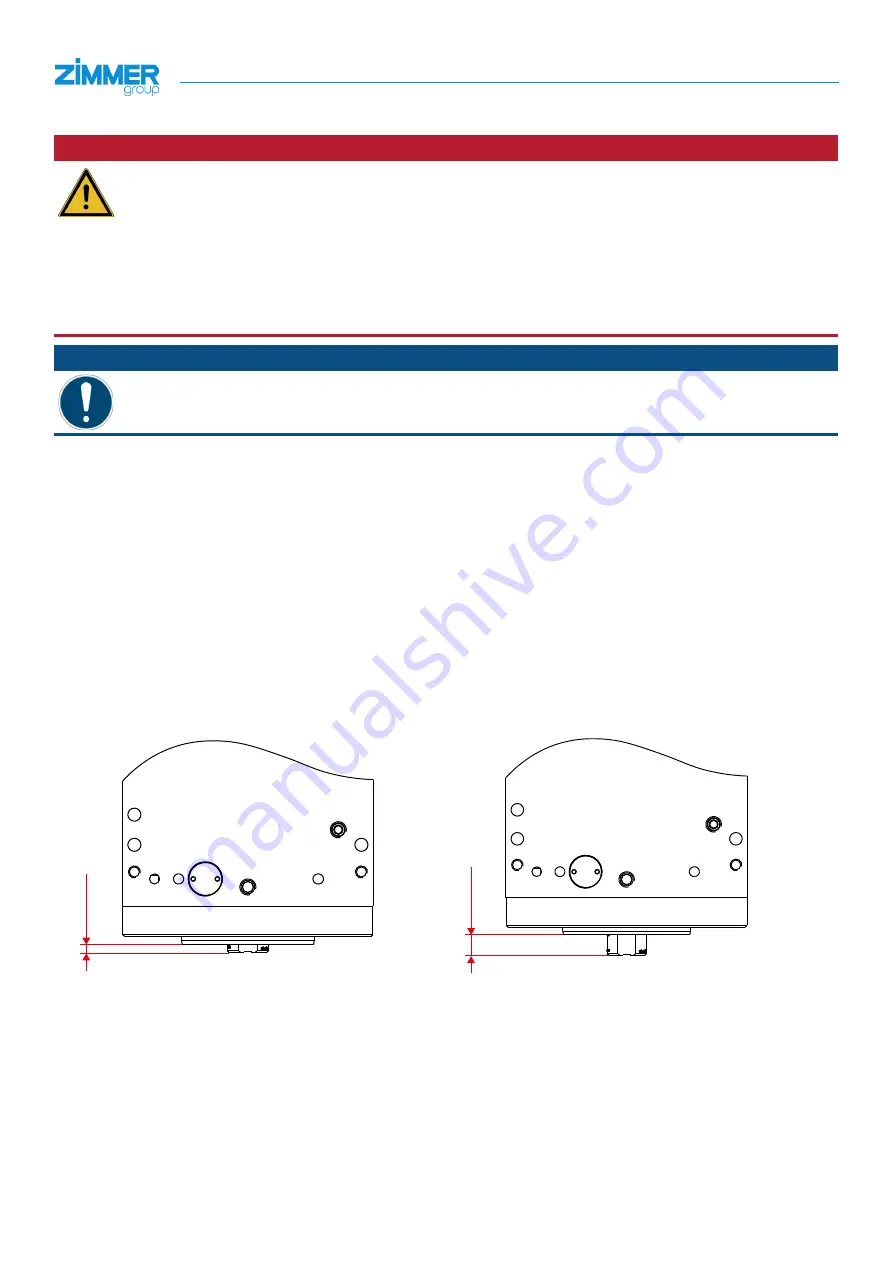

The clamping system is unclamped/extended if: Nominal dimension

X

= 10.5 +0.1 mm

►

Bleed the clamping system by using the machine control system.

Ö

The clamping system is retracted, "clamped without a tool" if: Nominal dimension

X

= 1.5 +0.1 mm

Sollmaß X eingefahr

en

Sollmaß X ausgefahr

en

►

Check the two positions of the clamping system to determine whether they are situated within the specified tolerance.

Ö

If the actual dimensions are NOT within the nominal dimensional tolerance, the product must not be operated!

In order to establish the correct setting dimensions, observe the installation instructions of the clamping set!

If it is ensured that the setting values correspond to the specifications, the following steps must be carried out:

►

Insert the tool or unit into the product in the axial direction.

►

Clamp the tool or unit by using the machine control system.

►

Check that the tool or unit fits correctly.

Ö

If an error message appears, repeat this process.

Ö

See table "Troubleshooting".