CLEANING, DECONTAMINATION AND STERILIZATION

17

If the lift out tray (REF 89-8510-459-48) is not being used, load the equipment into the automated washer in a wire basket. Make

sure to orient the equipment vertically to assist in drainage. Load the equipment carefully to prevent movement that may inhibit

proper cleaning and always avoid contact between multiple components.

The components should be positioned on the lift out tray following the diagrams printed on the lift out tray. Do not overload

the lift out tray.

AUTOMATED CLEANING AND DISINFECTION

Put medical devices in the automated washer. Avoid all contact between the devices (movement may damage devices and may

jeopardize the cleaning operation).

Put implements so that holes are aimed downwards to allow proper water drainage.

Start the automated washer.

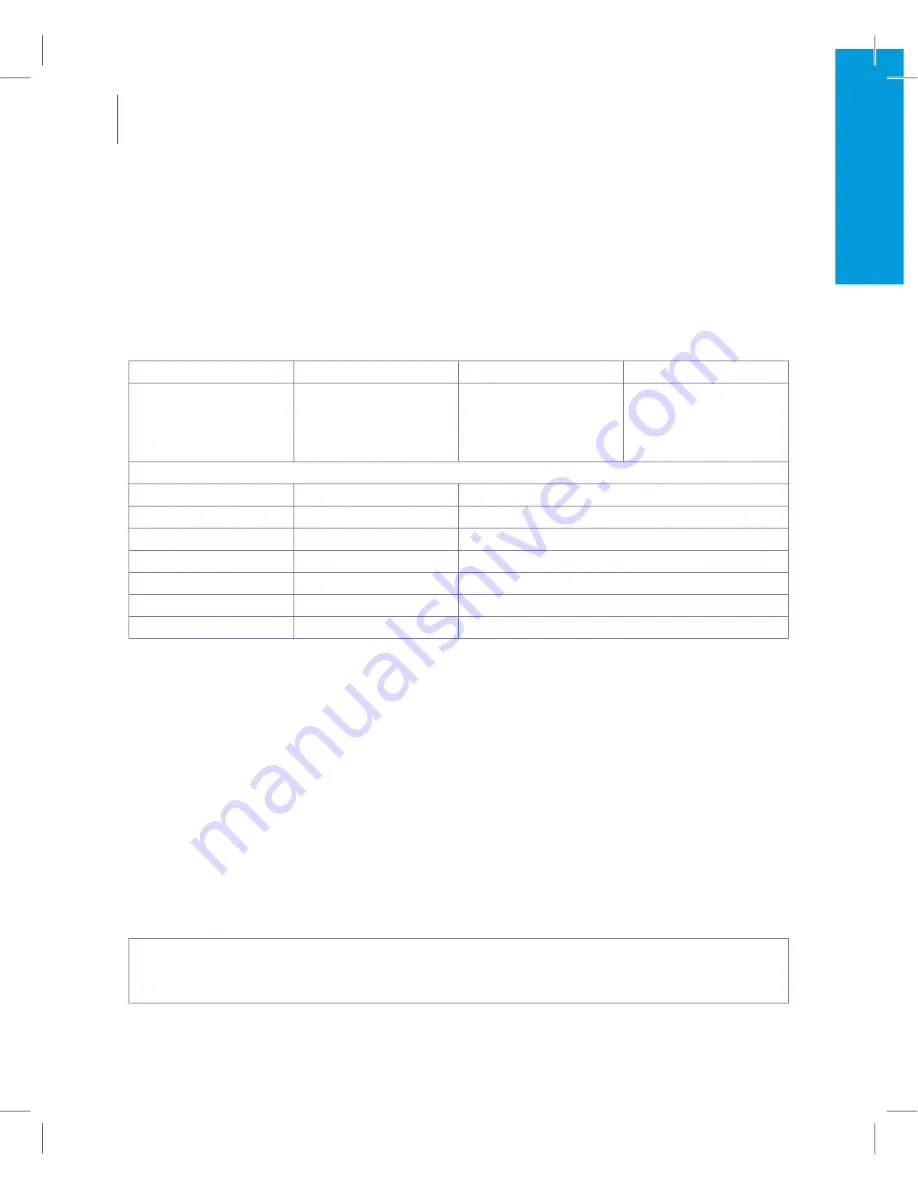

Automated cleaning and disinfection procedure

STEP DESCRIPTION

STEP INSTRUCTION

ACCESSORIES

DURATION

Automated washer

Place entire device into the

automated washer, placing

implements so that holes are

aligned downward.

−

Automated washer

− Disassembled device

−

Washer cleaning solution

− Washer neutralizing

solution

Minimum total cycle time: 51

minutes when including all

steps below.

Validated automated washer cycle

Step

Minimum time

Recommended temperature

Pre-Wash

2:00 minutes

Water temperature 20°C (68°F)

Cleaning

5:00 minutes

Water temperature 55°C (131°F)

Neutralizing

2:00 minutes

Water temperature 20°C (68°F)

Rinse I

2:00 minutes

Water temperature 20°C (68°F)

Rinse II (Final)

5:00 minutes

Water temperature 93°C (200°F)

Drying

35:00 minutes

Chamber temperature 99°C (210°F)

Only washing parameters shown above have been validated for cleaning effectiveness.

However, the performance of

Zimmer

® UNIVERSAL Power System is not affected in case lower temperature and/or shorter dwell

time are used.

INSPECTION

Inspect each part of the devices to make sure all soil is removed.

If necessary, repeat the cleaning process.

STERILIZATION

The referenced steam sterilization cycle parameters listed below have been validated and provide a sterile result by steam

sterilization according to ANSI/AAMI/ISO 17665-1:2006, Sterilization of Health Care Products. Part 1: Moist Heat. The steam

sterilization process for these products has been validated to provide a sterility assurance level (SAL) of 10-6 or better when

using the sterilization cases (REF 89-8510-459-41 or REF 89-8510-459-42 or REF 89-8510-459-43 or REF 89-8510-459-45 or REF

89-8510-459-46). Use of these UNIVERSAL sterilization cases is strongly recommended.

Please note that the processes described in this chapter are the only ones covered by our warranty conditions. Any other

sterilization processes must not be used, with the risk to induce a premature wear and a deterioration of the device.

The steam sterilization procedure must be carried out in a qualified autoclave.

The components should be positioned in the cases following the diagrams printed on the cases. Do not overload the cases.

CAUTIONS

:

•

For pneumatic handpiece:

Remove all washing caps (REF 89-8510-455-50, REF 89-8510-555-00) on hoses and on handpiece

air inlet before the sterilization process.

•

Do not subject any cap to the sterilization process.

ENGLISH

Summary of Contents for Universal Power System

Page 1: ...Zimmer UNIVERSAL Power System Instruction Manual Battery Electric ...

Page 24: ...26 ...

Page 25: ......