- CS Commercial HydroTap - Installation Instructions - 09.16 v3.01

Page 17 of 20

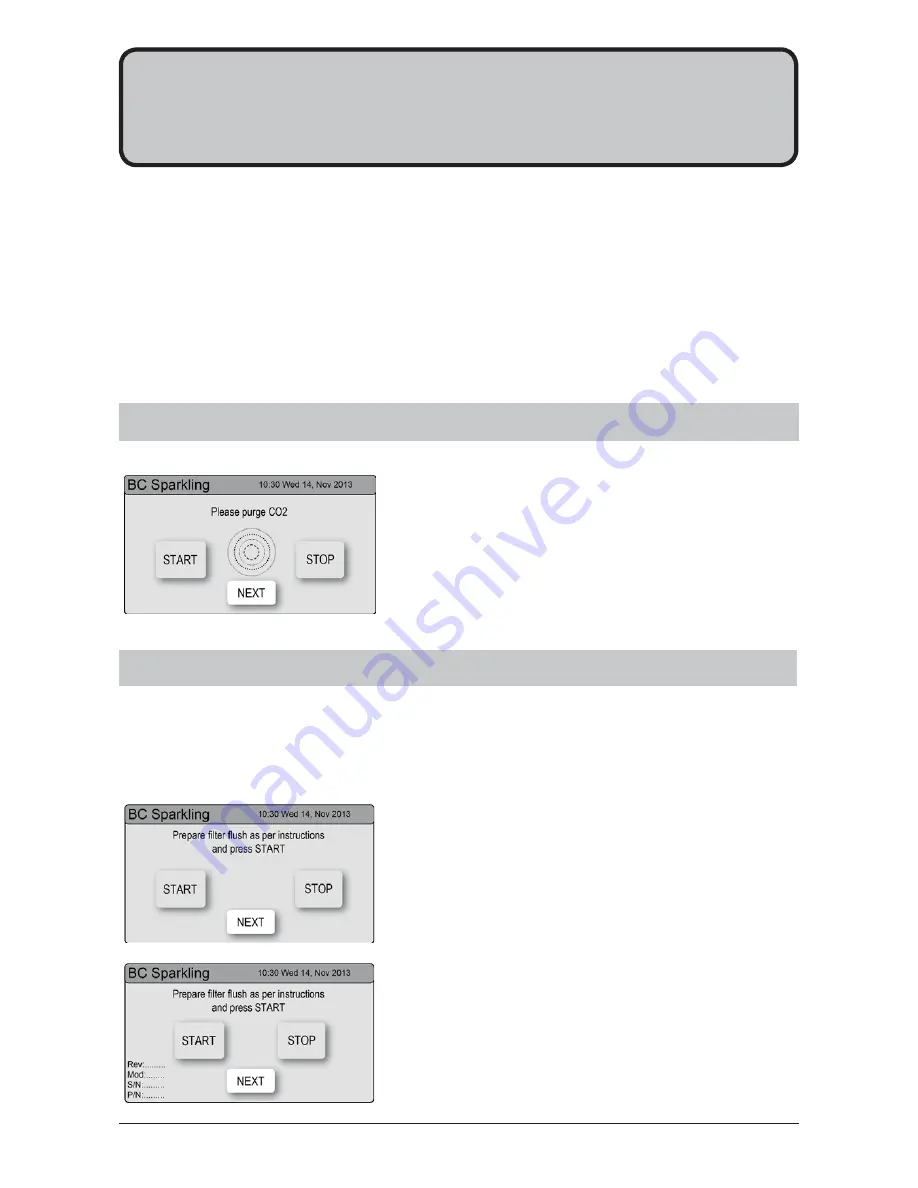

1.

Note:

You will need to Press the [Start] [Stop] buttons

to start and stop the filter flush.

2.

Turn the flush line stop cock ON (See diagram).

3.

Press [Start] and allow at least 10 litres of water to flush

through the filter.

4.

The product details will be displayed in the screen.

5.

Once the filter flush is finished, Turn the stop cock OFF

then press [Stop] to end filter flush mode.

6.

Press [Next] for the Boiling Calibration screen.

Have a 10L bucket or similar container (not supplied) at the ready to hold a quantity of water that will be

ejected while the Filter Flush Mode is in operation. Open the filter access door on the front of the HydroTap

and the filter cartridge will be exposed. Located to the rear RHS of the cartridge is a flush line, approx 600mm

long and the flush line stop cock. Place the valve end of the flush line into the 10L bucket or container.

5.2

-

Filter Flush

Section 5

Commissioning

5.1

-

CO2 Purge

1.

Press the [START] button to commence the purging

process.

2.

Purge for 10 seconds and ensure all water has stopped

flowing through the tap. (You will hear the CO

2

gas

escaping from the tap).

3.

Press the [Stop] button.

4.

Press [Next] for the filter flush screen

The HydroTap is now ready to be commissioned.

•

Turn ON the water and gas and check for any leaks.

•

Turn the power ON at the GPO

•

Familiarise yourself with the operation of the Tap, in preparation for use (See User Guide)

•

Follow the instructions below (and review Section C of the User Guide).

•

Initially you will be prompted to select a language

•

After commissioning, the system may be customised by selecting further options in

Section G - Settings, within the User Guide.