MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

25

ZI-BTS350

13.1.4

Water supply

The water connection, you can connect a water supply.

This allows you to achieve a uniform cooling of the blade and reduce the formation of dust

strongly.

Operation

Review safe working environment, safe work clothing, machine before putting on faultless

and operational condition.

Saw at Max. , align top position, fold down section markers (linkage with red roller) to cut

line. Align the saw blade to cut line.

gate valve at the bottom of the water tank open.

Start the engine

blade wind down slowly deepen the cut until the desired depth of cut is reached.

Cut only as fast as it allows the material. If the blade lifts the feed, you slow down the feed!

If desired cutting depth of more than 90mm, this should be achieved through two steps.

The proper sense of the proper feed speed is important. Please slide the machine fast enough

that the blade can work into the material, but once they realize that the speed decreases,

reduce the feed.

No lateral pressure on the blade.

Can not operate without blade guard mounted!

Do not force the blade into the material. Let the wheel going into the material alone.

Do not perform long continuous cuts.

No Dry cutting saw blades are suitable for wet cutting.

No curves intersect. Not inclined to fix blade material.

14

MAINTENANCE

14.1

Maintenance activities

Check the belt tension and adjust as required

Lubricate the bearings of the diamond saw blade axis daily

Before each use, the blade is in good condition and tight fit

Before each use the air filter is clean.

Before each use screw connections for tightness

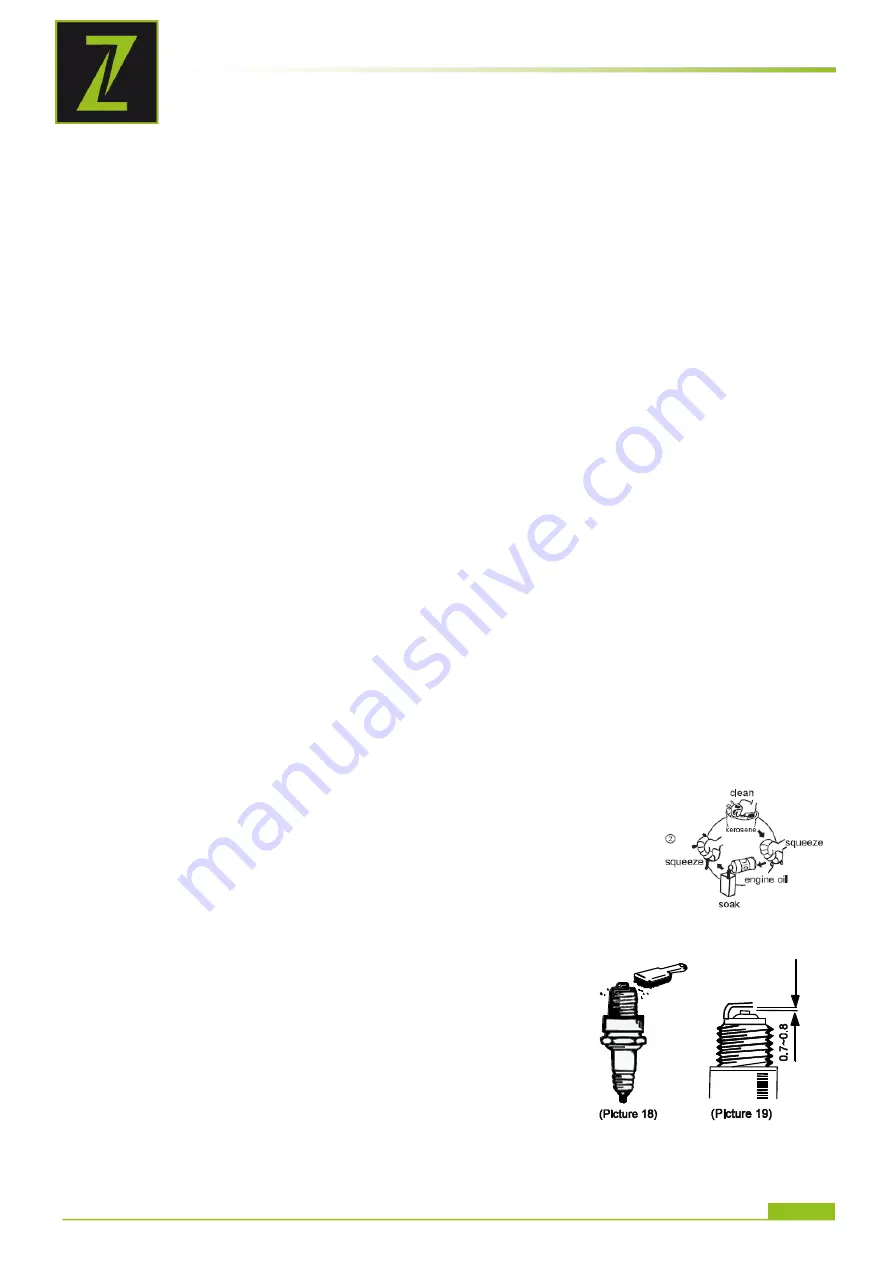

Air filter (every 100 hours)

1.

Remove the air filter.

2.

Clean it in a solution.

3.

Drops of engine oil on the air filter.

4.

Waste engine oil to remove from the air filter by wring it out.

CAUTION: NEVER WITHOUT ENGINE AIR FILTER OR

MAINTAINTED AIR FILTER WITH NOT OPERATE

14.2

Spark plug (every 50h)

Remove the spark plug contact.

Remove any debris with a brush.

Inspect the spark plug for discoloration.

Check the contact gap. Standard: 0.7 ~ 0.8mm