OPERATION

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

29

ZI-RPE160C

16.1

Information on Initial Start-up

N O T I C E

Note that the machine is delivered without engine oil and fuel. Make sure that this

equipment is filled up before the machine is put into operation for the first time.

ATTENTION: The machine does not start until the engine oil has been refilled to the

upper limit.

16.1.1

Test Run Initial Start-up

Let the machine run idle for about 3 minutes.

Pay attention to abnormal noises.

Pay attention to the exhaust fumes (too black, too white)?

16.1.2

Notes on the first 20 operating hours

In order to optimize the life expectancy of your machine, the following points should be observed:

Do not operate the engine for the first 20 operating hours @ maximum load (this also

applies to used engines after extensive maintenance). This means lower speed and

lower maximum working load than during normal operation.

Change the engine oil after the first 20 hours of operation.

16.2

Operating Instructions

Never use the recoil-starter while the engine is running. This will damage the engine.

The pull mechanism for changing the engine speed is limited by an adjusting screw.

This is factory set. Never change this setting on your own, you could overload the

motor.

Do not operate the machine on slopes of more than 20°, as even with an optimum oil

level the engine may not be supplied with sufficient lubrication.

In the direction of the vibratory plate and within a range of one meter around the

vibrator, nobody but the operator must stand.

During the compaction the soil should first be compacted about 10 to 15 cm inside the

edge two to three times, then the edge should be compacted.

When working inside the building, the vibrating plate or eccentric block must not attach

the walls.

If several vibrator plates are used simultaneously on one surface, the parallel distance

between the machines should not be less than five metres and the distance between

the front and rear machines should not be less than ten metres.

If the machine is working in an environment e.g. on soft or uneven ground, make sure

to reduce the horsepower to the lowest level to prevent the machine from sinking. On

slopes (max. 20° allowed!!!), make sure that the machine does not tilt.

Pay particular attention to the following particularly dangerous areas:

During tunnel work, good ventilation must be provided to prevent accidents.

In addition, the ventilation must be monitored.

There is a risk of electric shock near overhead lines. Persons not in control of

the machine should not be in the near or far working area.

The stability of the machine should be taken into account when working and

parking the machine in order to avoid hazards. During tunnel work, good

ventilation must be provided to prevent accidents. In addition, there must be

a functioning control system for the functioning of the fresh air supply.

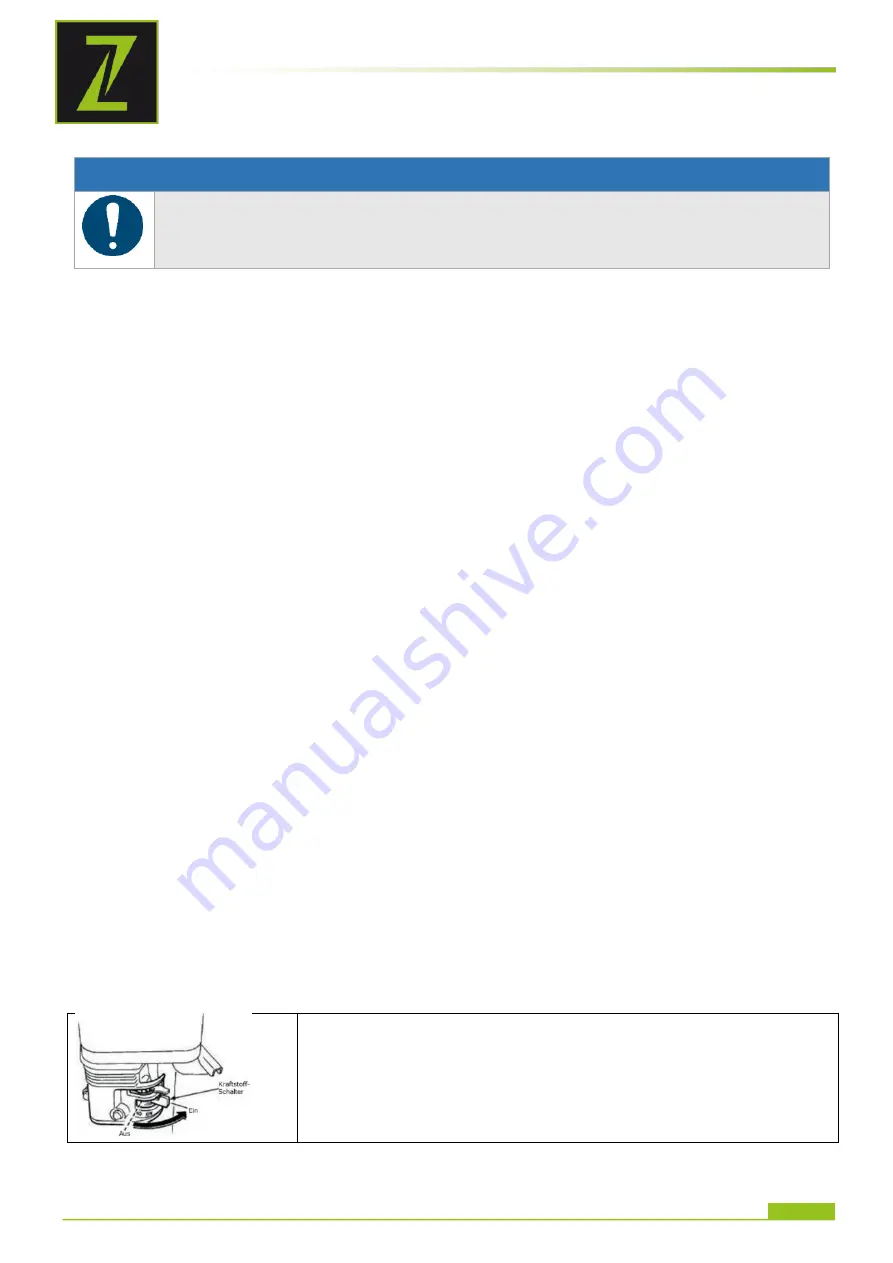

16.3

Starting the machine

1.

Turn the fuel tap to Position „On“