OPERATION

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

28

ZI-RPE160C

3.

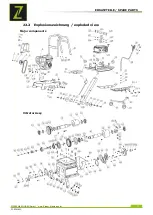

Push the dipstick into the opening, but do not screw it in.

(Make sure that the dipstick has really been pushed in

completely).

4.

Pull out the oil dipstick again and read off the oil level.

There are two markings for this - see illustration on the

left.

5.

If the oil level is low, refill the recommended oil up to the

upper edge (max. filling volume refer to the tech. data).

6.

Push in the oil dipstick again and tighten.

15.1.2

Checking the fuel tank level

N O T I C E

Observe the safety regulations for fuel control. Filter the fuel during refuelling to

prevent foreign particles from entering the combustion chamber. Wipe up leaked fuel.

Screw on the tank cap (sits on the fuel tank).

Level check in the form of a visual inspection. If necessary, top up with fuel with

the appropriate octane number (RON 95).

Close the fuel filler cap tightly after refuelling.

15.1.3

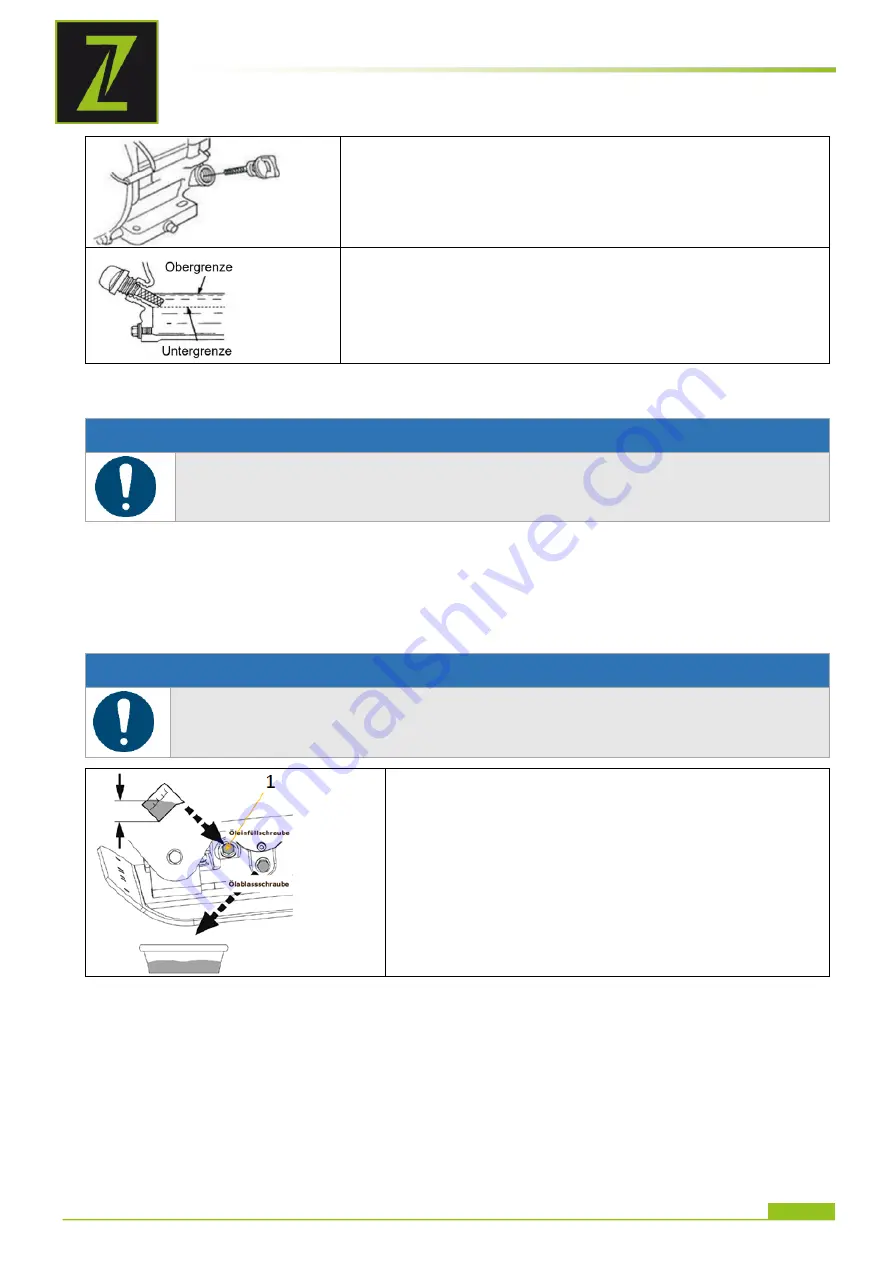

Checking exciter oil level

N O T I C E

Too low oil level will damage the machine and shorten the life of the machine.

Therefore, check the exciter oil level before every start and top up the exciter oil if

necessary.

1. place the machine horizontally

2. open the oil filler plug (1).

3. check the oil level. Oil should reach to the beginning

of the thread of the filling hole.

4. top up exciter oil if necessary

5. mount and tighten the oil filler plug (1).

16

OPERATION

Save the working environment before you start compressing.

Only put the machine into operation after you have read and understood the safety

instructions and carried out the necessary measures before initial commissioning.

The correct moisture content of the soil is very important for correct compaction.

Compaction of dry materials is facilitated by moistening the material. Too much

moisture, on the other hand, leaves water-filled cavities which weaken the load-

bearing capacity of the soil.

Wetness or excessive irrigation can lead to overloading and engine death.