MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

31

ZI-RPE160C

17

MAINTENANCE

W A R N I N G

Hot surfaces and rotating machine parts while the engine is running can cause

serious injury or even death. Always stop the machine before carrying out any

conversion, adjustment, cleaning or maintenance work and secure it against

unintentional restarting.

17.1

Maintenance and Servicing Plan

17.1.1

Table of Measures

What to do?

Frequency

Check fuel level

before each start-up

Check engine oil level

before each start-up

Control of the operating elements

before each start-up

Check for damaged parts

before each start-up

Checking for loose or lost screws

before each start-up

Change engine oil

After first 20h, then every 100h

Check V-belt

every 50 h; replacement after 300 h or 1 year

Change exciter oil

After first 50h, then every 200h

Air filter cleaning

every 50 h, replacement after 300 h or 1 year

Spark plug test

every 100 h; replacement after 300 h or 1year

The specified intervals refer to working under "normal" operating conditions. Depending on the

load, a change/exchange may also be necessary at an earlier point in time.

17.2

Changing the exciter oil

N O T I C E

Waste oils are toxic and must not be released into the environment!

Contact your local authorities for information on proper disposal.

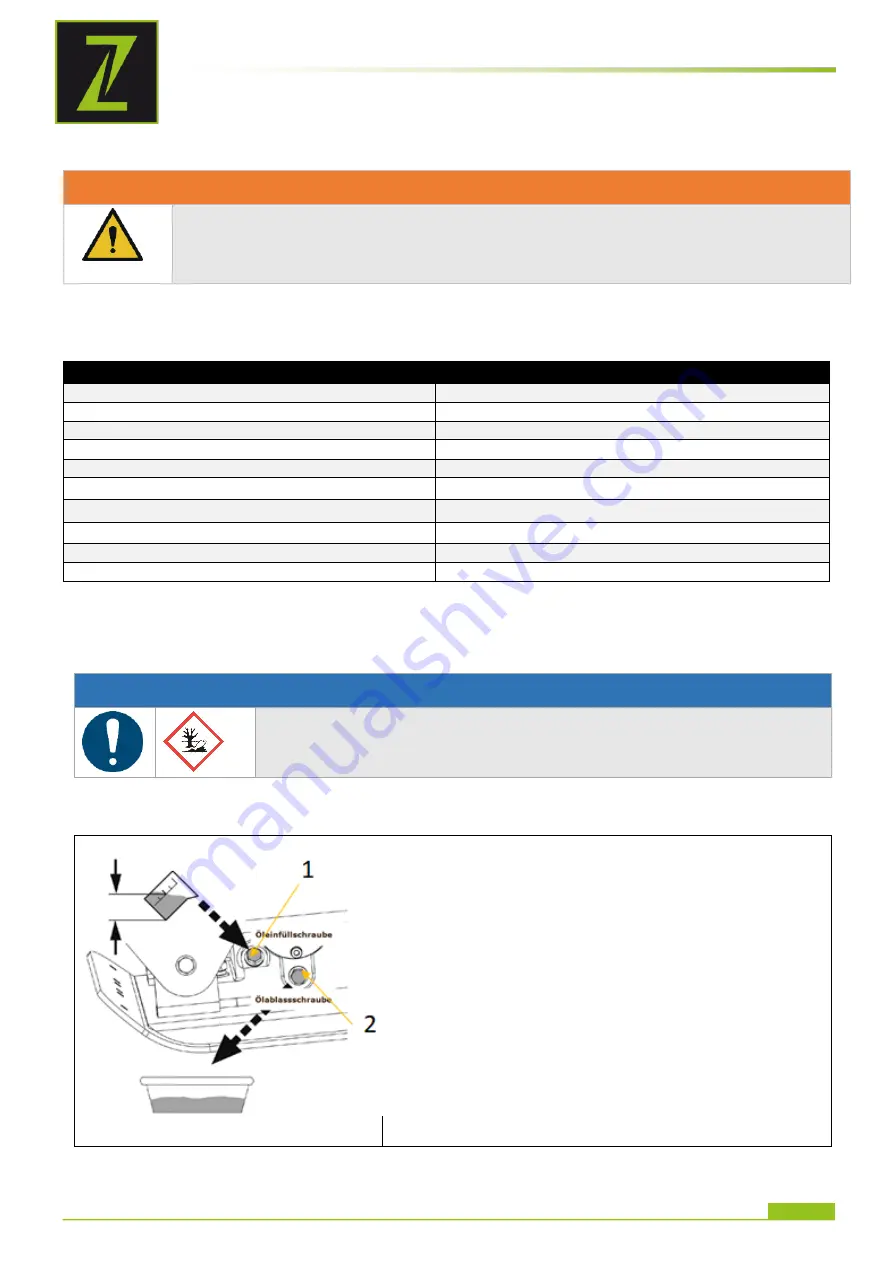

17.2.1

Exciter oil check / change

Check

1. place the machine horizontally

2. open the oil filler plug (1).

3. check the oil level. Oil should reach to the start of

the thread of the filling hole.

4. top up exciter oil if necessary

5. mount and tighten the oil filler plug (1).

Change

1. open oil filler plug (1) and oil drain plug (2).

2. tilt the machine and keep it tilted until the oil has

run out. Collect oil in a suitable container!

3. place the machine horizontally and fit and tighten

the oil drain plug (2).

4. fill in exciter oil through the oil filling hole

(~400ml).

Fit oil filler plug (1) and tighten securely.