MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

33

ZI-RPE160C

Loose or worn V-belts reduce power transmission efficiency, result in poor compaction

performance and shorten the service life of the belt itself. Therefore, always check the V-belt

tension at the specified intervals.

17.5.1

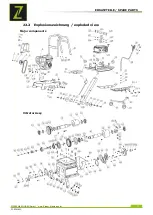

Checking the V-Belt tension

Loosen screws (S) of the V-belt cover (1)

and remove the V-belt cover. Use thumb

pressure to check the flexibility of the V-

belt.

If this is within approx. 10-15mm no

action is necessary. If the flexibility is

higher, the V-belt must be retightened (V-

belt tensioning) or replaced.

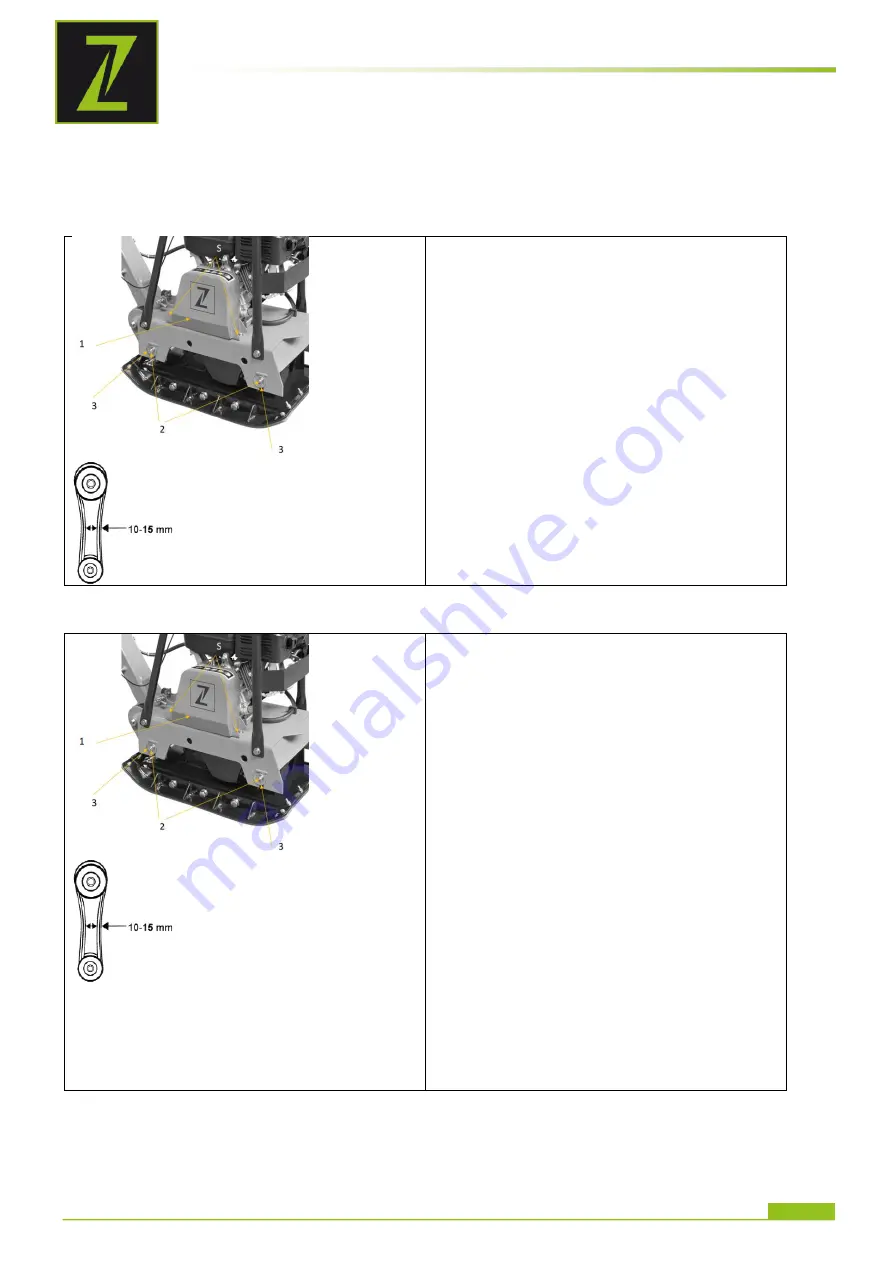

17.5.2

Tensioning / change of V-Belt

Tensioning

- Remove the V-belt cover (1).

- Loosen all four nuts (2) two on each side

- Turn the eccentric disc (3) upwards to

increase the distance between the two

pulleys and thus the belt tension.

- retighten all four nuts (2)

- Check V-belt tension

- If suitable, refit the V-belt cover (1) and

fix it with the screws (S). Otherwise

readjust the belt tension.

Change

- Remove the V-belt cover (1).

- Loosen all four nuts (2) two on each side

- Reduce belt tension by turning the

eccentric discs (3) downwards (distance

between the pulleys is minimised).

- pull the old belt from the pulley and

replace it with a new one.

- Tensioning the belt

- Retighten all four nuts (2)

- Check V-belt tension

- If suitable, refit the V-belt cover (1) and

fix it with the screws (S). Otherwise

readjust the belt tension.

17.5.3

Checking the clutch

Check the clutch at the same time as the V-belt. With the belt removed, visually check

the outside for seizure and the "V" groove for wear and damage. Clean the V-groove as

required. If the clutch shoe is worn, the power transmission becomes insufficient.