OPERATION

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

21

ZI-BG100Y

15

OPERATION

Check scope of delivery

After delivery, check the machine immediately for transport damage and missing Parts.

Checklist before each use

N O T I C E

The use of paint thinners, petrol, aggressive chemicals or abrasives leads to material damage

to the surfaces! Therefore use only mild detergents for cleaning!

Clean the machine and remove dirt and dust if necessary.

If the air filter is dirty, blow the filter cartridge from the inside by moving a jet of dry

compressed air up and down. Continue until all dust has been removed. Replace the

air filter with a new one if necessary.

Check the carburettor for external dirt and dust and clean it with dry compressed air if

necessary.

Check the nuts and bolts for tightness. (Screws or bolts loosened by vibrations can

lead to accidents!)

15.2.1

Checking the engine oil level

N O T I C E

Too low an oil level will damage the engine and shorten the life of the machine.

Therefore, check the engine oil level before every start and top up the engine oil if

necessary.

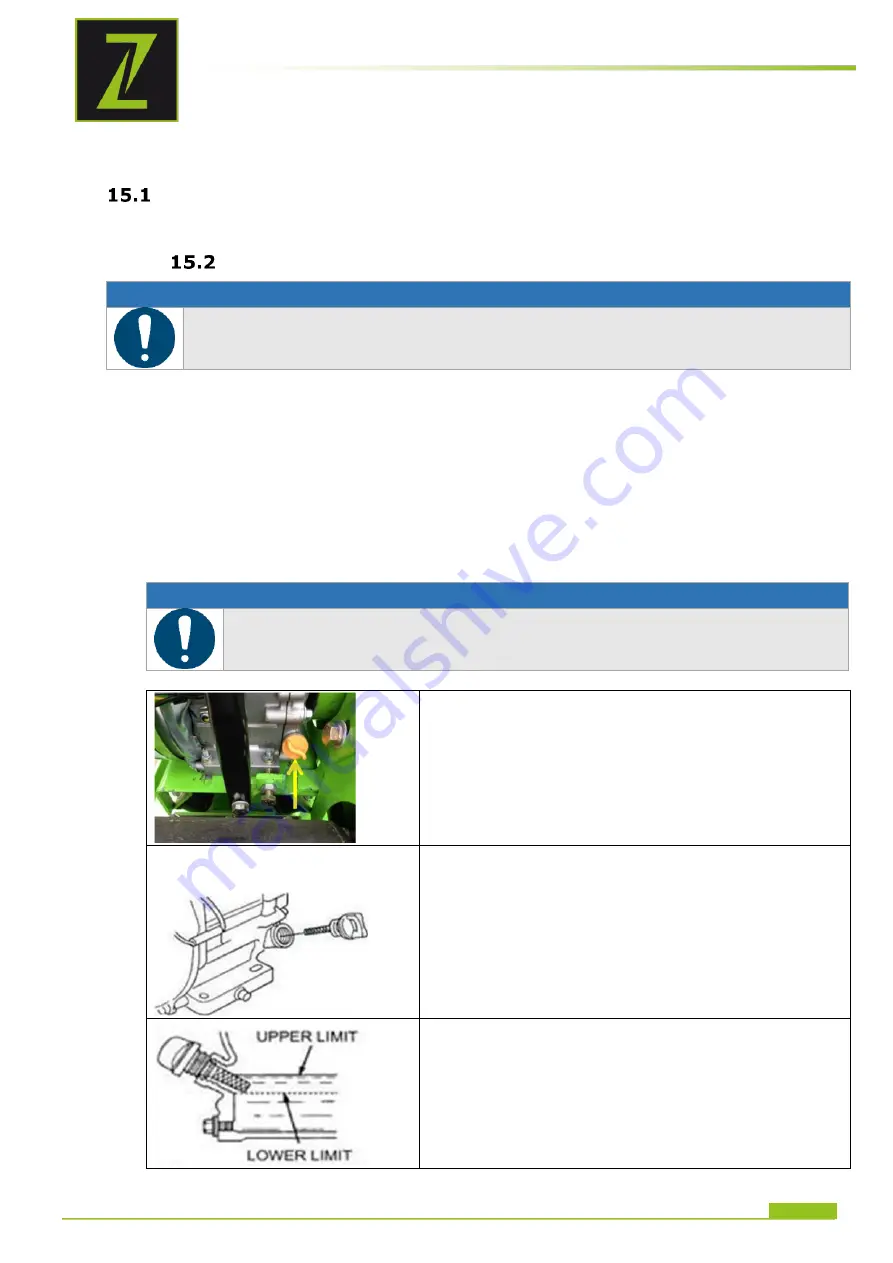

1.

To check the engine oil level, place the machine

on a safe, level surface. Switch off the engine and

allow the machine to stand for ten minutes so that

the circulating oil can collect in the oil pan.

2.

Unscrew the oil dipstick and wipe with a clean,

lint-free cloth or a non-fibrous paper towel.

3.

Push the dipstick into the opening, but do not

screw it in. (Make sure that the dipstick has really

been pushed in completely).

4.

Pull out the oil dipstick again and read off the oil

level. There are two markings for this - see

illustration on the left.

5.

If the oil level is low, refill the recommended oil

up to the upper edge (maximum filling volume:

approx. 0.5 litres).

6.

Push in the oil dipstick again and tighten.