MAINTENANCE

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

17

ZI-COM50-10

15

MAINTENANCE

A T T E N T I O N

Bevor maintenance:

Switch off and disconnect from the power supply!

Let cool down the air compressor!

Depressurize the air tank

The machine does not require intense maintenance. However, to ensure a long lifespan, we strongly

recommend following the upkeep and maintenance plan.

Repairs must be carried out by specialists! Use original ZIPPER parts only!

N O T I C E

Only a properly maintained equipment may be a satisfactory tool. Care and maintenance deficiencies

can cause unpredictable accidents and injuries.

Repairs should be performed only by authorized service centers.

Improper operation may damage the equipment or endanger your safety.

15.1

Cleaning

Keep the safety devices free of dirt and dust as far as possible. Wipe the machine with a clean cloth or

blow it with compressed air at low pressure.

N O T I C E

Do not use cleaning agents or solvents; these could attack the plastic parts of the

machine!

Put on all coatless flats a thin coat of oil.

15.2

Maintenance plan

Controls for the maintenance of the machine

Loose or lost screws, nuts, bolts

Regularly prior to each operation

Damage of any part of the machine

Regularly prior to each operation

Machine cleaning

Regularly after operation

Air filter cleaning

Every 20-30 working hours

15.2.1

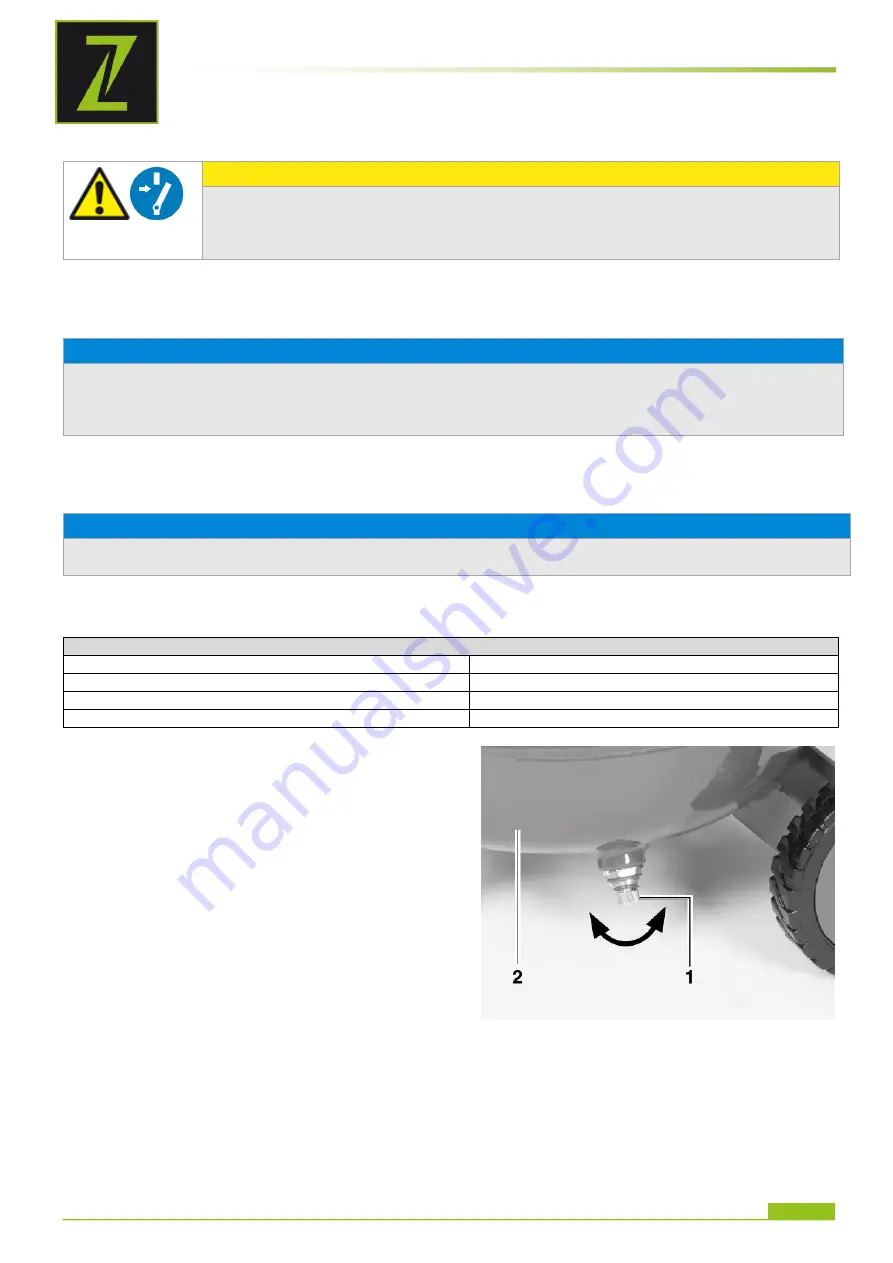

Condensation water

To ensure a long service life of the pressure vessel,

drain off the condensed water by opening the drain

screw each time after using. Take care to perform

only with max. 1bar pressure.

Check the pressure vessel for rust and damage

before each operation. The compressor must not be

operated with a damaged or rusty pressure vessel. If

any damage is found, please contact the customer

service center.

15.2.2

Storage

If the machine is stored for longer than 30 days:

•

Let the machine cool down

•

Clean the machine and dry

Depressurize the air tank.

•

Store in a dry, out of reach of children place, well packaged (protection against cuts)