CLEANING, MAINTENANCE, STORGE, DISPOSAL

ZIPPER MASCHINEN GmbH www.Zipper-Maschinen.at

28

ZI-RMM94H

28

16

CLEANING, MAINTENANCE, STORGE, DISPOSAL

Cleaning

N O T E

Wrong cleaning agents can attack the varnish of the machine. Do not use solvents,

nitro thinners, or other cleaning agents that could damage the machine's paint.

Observe the information and instructions of the cleaning agent manufacturer!

Prepare the surfaces and coat the bare machine parts with an acid-free lubricating oil.

Subsequently, regular cleaning is a prerequisite for the safe operation of the machine and a long

service life of the machine. Therefore, clean the machine after each use, but at least once a

week.

Maintenance

W A R N I N G

Handling the machine with the power supply up can lead to serious injuries or even

death. Always disconnect the machine from the power supply before servicing or

maintenance work and secure it against unintentional or unauthorised reconnection!

The machine is low-maintenance and only a few parts have to be serviced. Nevertheless,

malfunctions or defects which could impair the safety of the user must be rectified immediately!

Before each operation, check that the safety devices are in perfect condition.

Check the connections for tightness at least once a week.

Regularly check that the warning and safety labels on the machine are in perfect and

legible condition.

Vent the machine 3-4 times a year.

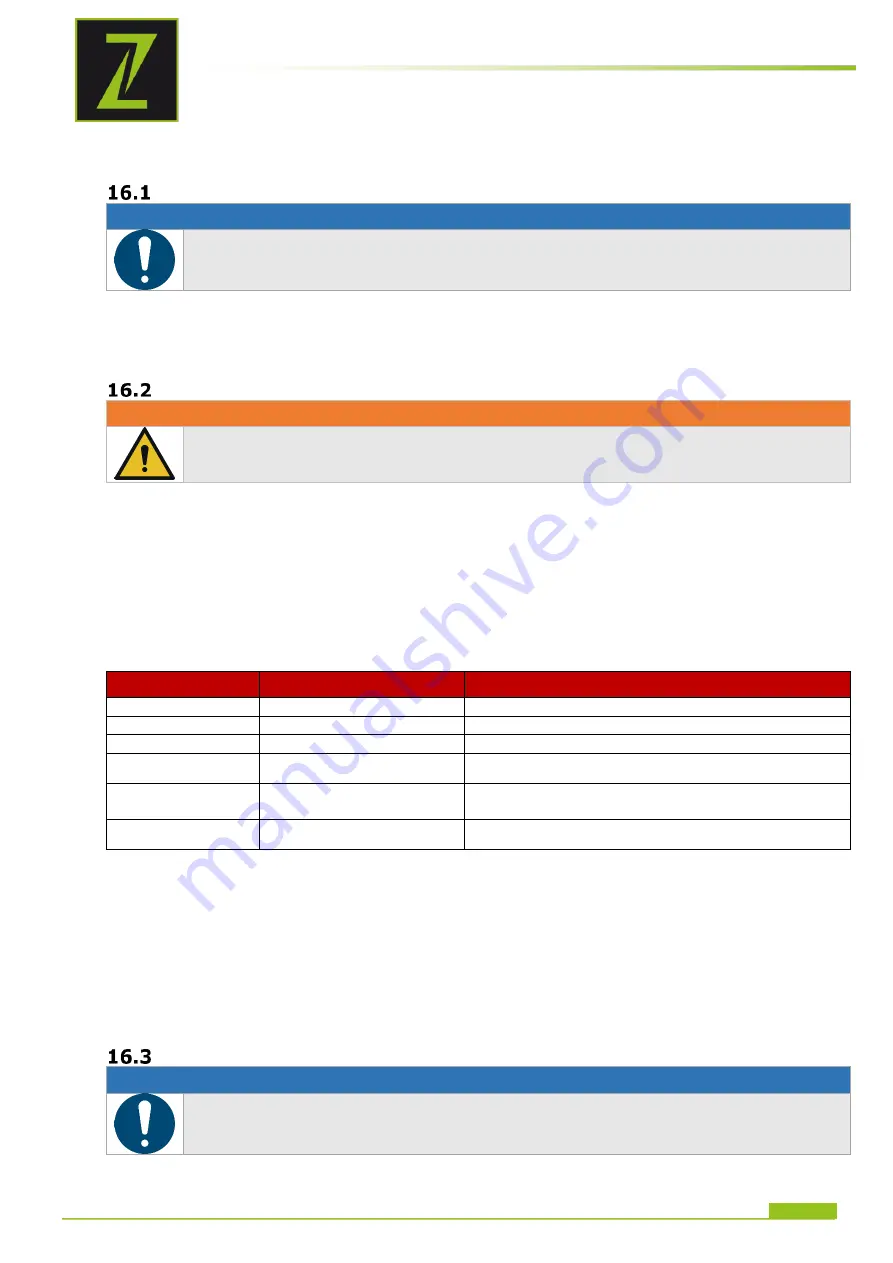

16.2.1

Maintenance schedule

The type and degree of machine wear depend on the operating conditions. The following intervals

apply when the machine is used within the specified limits:

Intervall

Komponente

Aktivität

Before usage

Turntable

clean

Before usage

Oil level

Check and refill

Before usage

Jaws

Lubriacte

1 x month

Screw connection

Check and re-tighten

1 x month

Moving parts

lubricate

1 x month

Drive belt tension

Check and re-adjust

16.2.1

Checking the lubricating oil level

Prüfen Sie den Schmierölstand im Schmiermittelbehälter. Falls nötig füllen Sie Schmieröl mit

Viskositätsgrad SAE 30 nach.

16.2.2

Antriebsriemenspannung prüfen

Remove the cover from the left side of the tire changer to gain access to the drive belt. To do

this, loosen and remove the four fastening screws of the cover and remove it. If the belt is no

longer sufficiently tensioned, you can tension it by turning an adjusting screw located on the

motor plate.

Storage

N O T E

Improper storage can damage and destroy important machine parts. Store packed or

unpacked parts only under the intended ambient conditions!