ASSEMBLY

Z.I.P.P.E.R Maschinen Austria

www.Zipper-maschinen.at

Seite 32

HOLZSPALTER / LOG SPLITTER ZI-HS8PT / ZI-HS10T / ZI-HS12T

13.2.5

The workplace

Choose a suitable place for the machine.

Observe the safety requirements of Chapter 12.

Make sure that the floor can support the weight of the machine. The machine must be leveled on

all bases simultaneously.

You must also ensure all round a distance of at least 0.8 m around the machine. Before and be-

hind the machine must be made for necessary clearance for the supply of long workpieces.

13.2.6

Transport of the log splitter to the work area

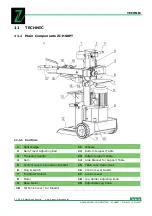

The log splitter is equipped with two wheels for easy transporting. To move the log splitter to

take the carrying handle (2 or 3) in the hand and tilt the splitter carefully. Take care that the

bleed screw is closed.

If you use a crane for transporting the log splitter, attach a suitable lifting tape on the housing

and lift the machine carefully. Never operate the crane hook hook on the handle.

13.2.7

Checks before initial start-up

Checking the strength of all screw

Inspect the machine for concealed damage , eg by transport.

Verification of the electrical connection.

Make sure that the power is being protected circuit.

Make sure that will support the power, voltage and frequency of the motor of your power

supply.

It must be a grounding available!

Electrical work may only be performed by trained specialist !

Make sure your extension cord does not overload the engine of your log splitter !

Extension cable must not be longer than 10m and its cross -section must not be less than 2.5

mm ². Only well-insulated , use appropriate extension cord for outdoor activity.

Search from the work under consideration of the safety regulations. Store the wood to be split

logs within reach . Creating the split logs from the work area.

Order Before you edit the logs from exceeding the maximum length ( information, please refer

the technical data ) . If you want to split log with very thick diameter , it is recommended not

to exceed the maximum lengths . There are three different splitting length. Always choose the

appropriate height for each log length . Secure the table in the desired position always with the

locking device.

The supply cable so set that it can not be damaged ( by working ) .

Open the bleed screw. Turn the bleed screw a few turns on whenever you take the log splitter

in operation. Turn the bleed screw after operation completely .

Check the motor rotation direction . When you turn on the engine, the riving knife is automati-

cally go to the highest position . If the riving knife should already be in the top position , turn

by moving the two levers down the gap mechanism. Thus, the splitting wedge will move down.

ATTENTION!

Low oil level can lead to damage to the engine, thus shortening the life of your machine.

Warranty claims are excluded in deficient carried out repair and maintenance activities!