997-532-000-1, Issue 1

March 2006

15

EN54 & ISO 7240 2-8 Zone Conventional Fire Panel - Installation & Configuration Manual

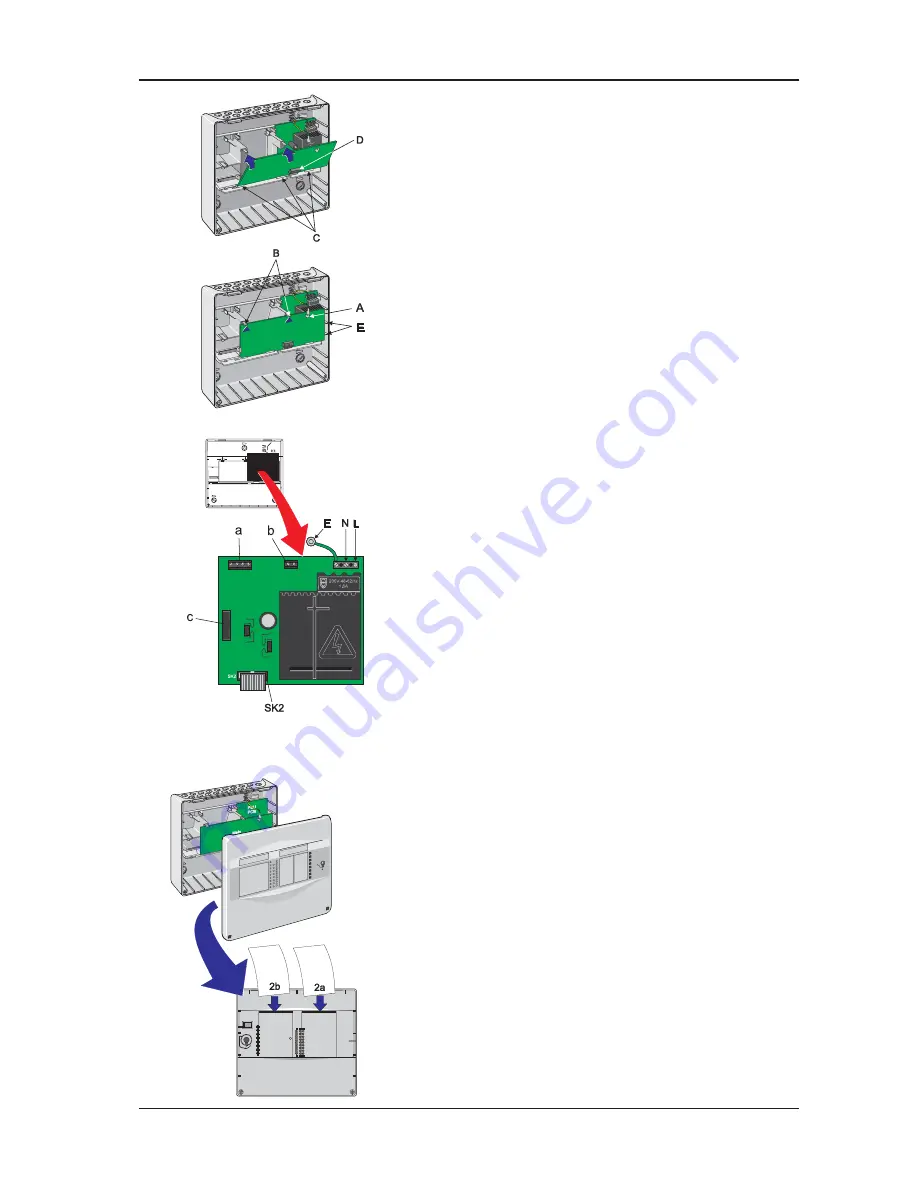

Refitting the Main PCB

The procedure for refitting the Main PCB is the reverse

of the removal procedure but note the following points:

When offering the Main PCB to the three locating tabs

(C) make sure that:

i

Make the ribbon cable connection at socket connector

SK4 (D) and re-connect the earth lead to the blade

connector (A).

ii

The ribbon cable is correctly located within the rebate

on the bottom edge of the Main PCB.

iii The PCB is correctly aligned with the rebates in the side

wall ribs (E) before gently pushing it home - confirmed by

audible clicks from the PCB-retaining clips (B).

Note:

For simplicity, the lettering of key items remains

the same as for the removal process.

5.2

PSU PCB

The PSU PCB provides all power requirements for the

panel when in quiescent and alarm conditions.

The mains supply live (L) and neutral (N) wiring is brought

into the panel and terminated at the Mains Termination

Block (MTB) located in the top right-hand corner of the

PCB. Refer to

Section 6.4 Powering the Panel

for details

on terminating the mains wiring at the MTB and the mains

safety earth at the earth post (E) in the back box.

The PCB is fitted with wiring connectors for:

a. Two sounder output circuits

b. One 24Vdc auxiliary output circuit.

c. Up to two, optional-fit 8-way Relay PCB(s).

Power and signal connection to the Main PCB is via the

16-way ribbon cable connector (SK2).

5.3

Label Inserts

The following paper text inserts are supplied for:

•

Zonal Fire/Fault information

•

Panel status.

To fit the text inserts proceed as follows:

1

Carefully remove all text inserts from the kit and select

the appropriate language. Discard the rest.

2

Make sure the moulded cover is removed from the

back box. With the rear face of the cover towards you:

a. The zonal text insert should be fed into the right-hand

(viewed from the back) entry slot and pushed all the way

down until all text is correctly displayed in the window.

b. To fit the panel status indication text insert use the left-

hand entry slot (viewed from the back) and push it

down until all the text is correctly displayed.

Summary of Contents for EN54

Page 41: ......