Featuring Revolutionary Target Control

™

(TC

™

)

Technology

The SuperScan

™

K4 wall scanner features TC

™

technology,

tuned to find wood studs while filtering out metallic false

positive objects such as plumbing, conduit, straps, brackets,

or ducts beneath surfaces. With TC

™

mode, users can utilize

“Trust but Verify” technique to help identify “safe-to-drill” zones

between adjacent drywall screws, nails, and protector plates.

Five scanning modes:

•

Target Control

™

(TC

™

)

locates center, edges, and direction

of wood studs (while ignoring metal) up to ¾" (19 mm) deep.

LCD will be backlit with a pale blue light.

In TC

™

mode, the LoLevel

™

Indicator indicates low (weak) signal

objects, such as plastic water pipes, plastic sewer drains, or

studs deeper than ¾" (19 mm). When compared to stud

signals, the LoLevel

™

Indicator may help differentiate studs

from false positives.

•

StudScan

locates center, edges, and direction of both

wood and metal studs up to ¾" (19 mm) deep.

LCD will

not be backlit in this mode.

In StudScan mode, the

Signal Strength Indicator uses the same icon as the LoLevel

™

Indicator. When TC

™

is off, a strong signal is indicated by full

signal strength bars.

•

DeepScan

®

locates center, edges, and direction of studs

(wood and metal) up to 1½" (38 mm) deep.

LCD will be

backlit with a green light.

•

Metal Scan

locates ferrous (magnetic) metal, such as steel,

up to 3" (75 mm) deep, and non-ferrous (non-magnetic)

metal, such as copper, up to 1½" (38 mm) deep.

LCD will

be backlit with a dark blue light.

•

AC Scan

locates live, unshielded AC wires behind drywall

up to 2" (50 mm) deep.

LCD will be backlit with a

red light.

NOTE:

TC

™

and StudScan use the same switch setting but

function differently. StudScan detects both wood and metal

studs

during scanning, while TC

™

detects only wood studs and

ignores metal. You can distinguish between the two modes

by the pale blue backlight on LCD in TC

™

mode. StudScan is

not backlit.

MetalliWarning

™

Indicator

will display when

metal is detected or dangerously close in TC

™

, StudScan, and

DeepScan

®

modes.

WIREWARNING

®

DETECTION

The Zircon

®

WireWarning

®

Detection

continuously detects

and alerts for live, unshielded AC (alternating current) wires in

any mode. When live AC voltage is detected, warning indicator

appears and screen starts flashing red until scanner is moved

sufficiently away from the live wire. When calibration begins

over an AC wire in any mode, AC icon will flash.

Use extreme

caution under these circumstances or whenever live

AC wiring is present.

WARNING

Scanner may not detect AC activity if wires

are more than 2" (50 mm) behind the scanned surface, in

concrete, encased in conduit, behind a plywood shear

wall or metallic wall covering, or if moisture is present in

the environment or scanned surface.

SCAN IN DEEPSCAN

®

MODE

DeepScan

®

mode is used to scan for deeper studs, or for use

with thicker walls. It can detect studs up to 1½" (38 mm) deep.

1.

Set mode to DeepScan

®

.

2.

Repeat steps 2–4 under STUDSCAN MODE section.

NOTE:

When scanning on thicker surfaces, device may not find

edges on surfaces thicker than ¾" (19 mm).

SCAN FOR METAL

Use Metal Scan mode to locate and narrow metal behind walls.

1.

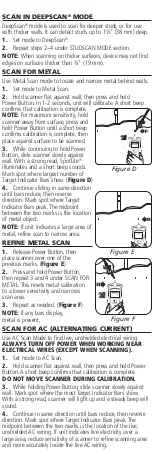

Set mode to Metal Scan.

2.

Hold scanner flat against wall, then press and hold

Power Button. In 1-2 seconds, unit will calibrate. A short beep

confirms that calibration is complete.

NOTE:

For maximum sensitivity, hold

scanner away from surface, press and

hold Power Button until a short beep

confirms calibration is complete, then

place against surface to be scanned.

3.

While continuing to hold Power

Button, slide scanner slowly against

wall. With a strong read, SpotLite

®

illuminates and a short beep sounds.

Mark spot where largest number of

Target Indicator Bars show. (

Figure D

)

4.

Continue sliding in same direction

until bars reduce, then reverse

direction. Mark spot where Target

Indicator Bars peak. The midpoint

between the two marks is the location

of metal object.

NOTE:

If unit indicates a large area of

metal, refine scan to narrow area.

REFINE METAL SCAN

1.

Release Power Button, then

place scanner over one of the

previous marks. (

Figure E

)

2.

Press and hold Power Button,

then repeat 3 and 4 under SCAN FOR

METAL. This resets metal calibration

to a lower sensitivity and narrows

scan area.

3.

Repeat as needed. (

Figure F

)

NOTE:

If any bars display,

metal is present.

SCAN FOR AC (ALTERNATING CURRENT)

Use AC Scan Mode to find live, unshielded electrical wiring.

ALWAYS TURN OFF POWER WHEN WORKING NEAR

ELECTRICAL WIRES (EXCEPT WHEN SCANNING).

1.

Set mode to AC Scan.

2.

Hold scanner flat against wall, then press and hold Power

Button. A short beep confirms that calibration is complete.

DO NOT MOVE SCANNER DURING CALIBRATION.

3.

While holding Power Button, slide scanner slowly against

wall. Mark spot where the most Target Indicator Bars show.

With a strong read, scanner will light up and a steady beep will

sound.

4.

Continue in same direction until bars reduce, then reverse

direction. Mark spot where Target Indicator Bars peak. The

midpoint between the two marks is the location of the live,

unshielded AC wiring. If unit indicates live electricity over a

large area, reduce sensitivity of scanner to refine scanning area

and more accurately locate the live AC wiring.

INSTALL 9-VOLT BATTERY

Always use a new 9V alkaline battery with an extended

expiration date at least 3 years beyond current date.

Match battery direction to image inside battery cavity.

WARNING

Do not rely exclusively on scanner to

locate items behind a surface. Use other information

to help locate items before penetrating the surface,

including construction plans, visible points of entry

of pipes and wiring into walls, such as in a

basement, and standard stud-spacing practices.

SELECT MODE / POWER UP

Move Mode Selector Switch to desired mode: Target Control

™

/

StudScan, DeepScan

®

, Metal Scan, or AC Scan.

To activate scanner, press and hold Power Button. Unit shuts off

1-2 seconds after Power Button is released.

FIND A CLEAN WOOD STUD IN TARGET

CONTROL

™

(TC

™

) MODE

TC

™

is designed to detect wood studs during

scanning.

For best results, hold scanner as shown and move

slowly when scanning.

Do not touch surface during

calibration or scan.

1.

Set mode to Target Control

™

/StudScan switch.

2.

Hold scanner flat against wall, then press and hold Power

Button. Unit will calibrate in 1–2 seconds. Proper calibration is

confirmed by a short beep, a flicker of

SpotLite

®

Pointer, and a flash of icons.

If a calibration error occurs, all icons

will flash continuously.

NOTE:

Screen will have a pale

blue backlight in TC

™

mode.

DO NOT MOVE SCANNER

DURING CALIBRATION.

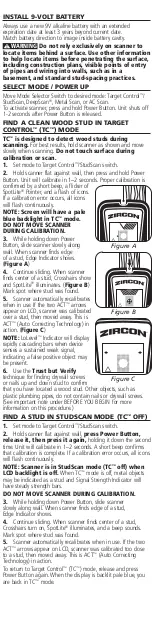

3.

While holding down Power

Button, slide scanner slowly along

wall. When scanner finds edge

of a stud, Edge Indicator shows.

(

Figure A

)

4.

Continue sliding. When scanner

finds center of a stud, Crosshairs show

and SpotLite

®

illuminates. (

Figure B

)

Mark spot where stud was found.

5.

Scanner automatically recalibrates

when in use. If the two ACT

™

arrows

appear on LCD, scanner was calibrated

over a stud, then moved away. This is

ACT

™

(Auto Correcting Technology) in

action. (

Figure C

)

NOTE:

LoLevel

™

Indicator will display

rapidly cascading bars when device

senses a sustained weak signal,

indicating a false positive object may

be present.

6.

Use the

Trust but Verify

technique for finding drywall screws

or nails up and down stud to confirm

that you have located a wood stud. Other objects, such as

plastic plumbing pipes, do not contain nails or drywall screws.

(See important note under BEFORE YOU BEGIN

for more

information on this procedure.)

FIND A STUD IN STUDSCAN MODE (TC

™

OFF)

1.

Set mode to Target Control

™

/StudScan switch.

2.

Hold scanner flat against wall,

press Power Button,

release it, then press it again,

holding it down the second

time. Unit will calibrate in 1–2 seconds. A short beep confirms

that calibration is complete. If a calibration error occurs, all icons

will flash continuously.

NOTE:

Scanner is in StudScan mode (TC

™

off) when

LCD backlight is off.

When TC

™

mode is off, metal objects

may be indicated as a stud and Signal Strength Indicator will

have steady strength bars.

DO NOT MOVE SCANNER DURING CALIBRATION.

3.

While holding down Power Button, slide scanner

slowly along wall. When scanner finds edge of a stud,

Edge Indicator shows.

4.

Continue sliding. When scanner finds center of a stud,

Crosshairs turn on, SpotLite

®

illuminates, and a beep sounds.

Mark spot where stud was found.

5.

Scanner automatically recalibrates when in use. If the two

ACT

™

arrows appear on LCD, scanner was calibrated too close

to a stud, then moved away. This is ACT

™

(Auto Correcting

Technology) in action.

To return to Target Control

™

(TC

™

) mode, release and press

Power Button again. When the display is backlit pale blue, you

are back in TC

™

mode.

NOTE:

AC Scan only detects live (hot) unshielded AC wiring.

Refer to the WARNING statement under WIREWARNING

®

DETECTION for important details and warnings

about AC detection.

REFINE AC SCAN

1.

Release Power Button, then position the scanner over one

of the previous marks. This will reset to a lower sensitivity and

narrow the scan area.

2.

Press and hold Power Button, then repeat 3 and 4 under

SCAN FOR AC.

3.

Repeat as needed for increased accuracy.

WARNING

DO NOT ASSUME THERE ARE NO LIVE

ELECTRICAL WIRES IN THE WALL. DO NOT TAKE

ACTIONS THAT COULD BE DANGEROUS IF THE WALL

CONTAINS A LIVE ELECTRICAL WIRE. ALWAYS TURN

OFF THE ELECTRICAL, GAS, AND WATER SUPPLIES

BEFORE PENETRATING A SURFACE. FAILURE TO

FOLLOW THESE INSTRUCTIONS MAY RESULT IN

ELECTRIC SHOCK, FIRE, AND/OR SERIOUS INJURY OR

PROPERTY DAMAGE.

WORKING WITH DIFFERENT MATERIALS

Wallpaper

Scanner functions normally on walls covered with

wallpaper or fabric, unless the materials are metallic foil,

contain metallic fibers, or are still wet after application.

Wallpaper may need to dry for several weeks after application.

Freshly painted walls

It may take a week or longer to dry

after application. If it is difficult to locate a stud in StudScan

Mode on dry or freshly-dried paint, switch to Metal Scan Mode

to locate the nails or drywall screws holding drywall to the studs.

Lath and plaster

Due to irregularities in plaster thickness,

it is difficult for this scanner to locate studs in any stud-scanning

mode. Switch mode to Metal Scan to locate the nail heads

holding wood lath to the studs. If the plaster has metal mesh

reinforcement, the scanner wil be unable to detect studs through

that material.

Highly textured walls or acoustic ceilings

When scanning a ceiling or wall with an uneven surface, place

thin cardboard on the surface to be scanned and scan over the

cardboard in DeepScan

®

Mode.

Wood flooring, subflooring, or gypsum drywall over

plywood sheathing

Use DeepScan

®

mode and move the

scanner slowly. This scanner cannot scan for wood studs and

joists through carpet and padding.

NOTE:

Sensing depth and accuracy can vary

depending on scanning environment conditions

such as mineral content, moisture, texture, and

consistency of the wall materials.

Electrical wiring and pipes

Depending on the proximity of

electrical wiring or pipes to the wall surface, scanner may detect

them in the same manner as studs.

Caution should always be used when nailing, cutting, or drilling

in walls, floors, and ceilings that may contain these items.

Studs

Studs are normally spaced 16" or 24" (40 cm or 60 cm)

apart on center and are 1½" (38 mm) wide. Anything closer

together, or of a different width, may not be a stud.

Figure A

Figure B

BEFORE YOU BEGIN

ZIRCON

®

STUD FINDERS WORK BY SENSING DENSITY CHANGES BEHIND THE WALL. OTHER OBJECTS CAN BE DETECTED,

ESPECIALLY IF THEY ARE VERY CLOSE TO THE WALL.

DO NOT ASSUME THAT EVERYTHING DETECTED IS A STUD.

- Always use a new 9V alkaline battery with an extended expiration date at least 3 years beyond the current date. Match battery

direction to the image inside of battery cavity.

- Do not rely exclusively on the scanner to locate items behind a surface. Use other information to help locate such items before

penetrating the surface, including construction plans, visible points of entry of pipes, wiring into walls such as in a basement,

and standard stud-spacing practices.

- Always start your scan in Target Control

™

(TC

™

) mode, which scans through standard single layer drywall up to ¾" (19 mm) deep.

- Always scan for studs at several different heights on the wall and mark the location of every target indicated by the stud finder. This

is called “mapping the wall.” Pipes and other objects will likely not give consistent readings from floor to ceiling, like a stud would.

- Studs normally run from floor to ceiling, except above and below windows and above doors.

- Readings should always be consistent and repeatable.

- Zircon

®

stud finders are recommended for interior use only.

- Other objects commonly contained in walls, floors, or ceilings are water pipes (plastic and metal), gas lines, firestops,

and electrical wiring.

- Sensing depth and accuracy can vary depending on scanning environment conditions, such as mineral content, moisture, texture,

and consistency of the wall materials.

- Depending on the proximity of electrical wiring or pipes to the wall surface, scanner may detect them in the same manner as studs.

Caution should always be used when nailing, cutting, or drilling in walls, floors, and ceilings that could

contain these items. Use extreme caution under these circumstances or whenever live AC wiring is present.

- Studs are normally spaced 16" or 24" (40 cm or 60 cm) apart on center, are normally 1½" (38 mm) wide, and may be separated

by firestops. Anything closer together, or of a different width, may not be a stud.

IMPORTANT:

Trust but Verify

is a technique that can help indicate “safe-to-drill” zones to minimize hitting existing metals

on a stud, such as nails, screws, and protector plates. When the Crosshairs show in TC

™

, run scanner vertically up and down the

stud. The stud indicators (Crosshairs, Edge Indicators, Target Indicator Bars, Target Spotlight, and SpotLite

®

Pointer) will all turn off

over screws and other metal, then turn on again when the stud is free from metal. The "safe-to-drill" zones are typically between

adjacent drywall screws, nails, or protector plates, assuming the builder properly installed metal protector plates on the stud, and

over plumbing and electrical. If stud indicators do not disappear when running vertically up and down the object in TC

™

mode, the

absence of drywall screws, nails, and protector plates indicates this could be a non-metallic object such as plastic plumbing or PEX

tubing, and should not be mistaken for a stud.

SuperScan

™

K4

Advanced Wall Scanner

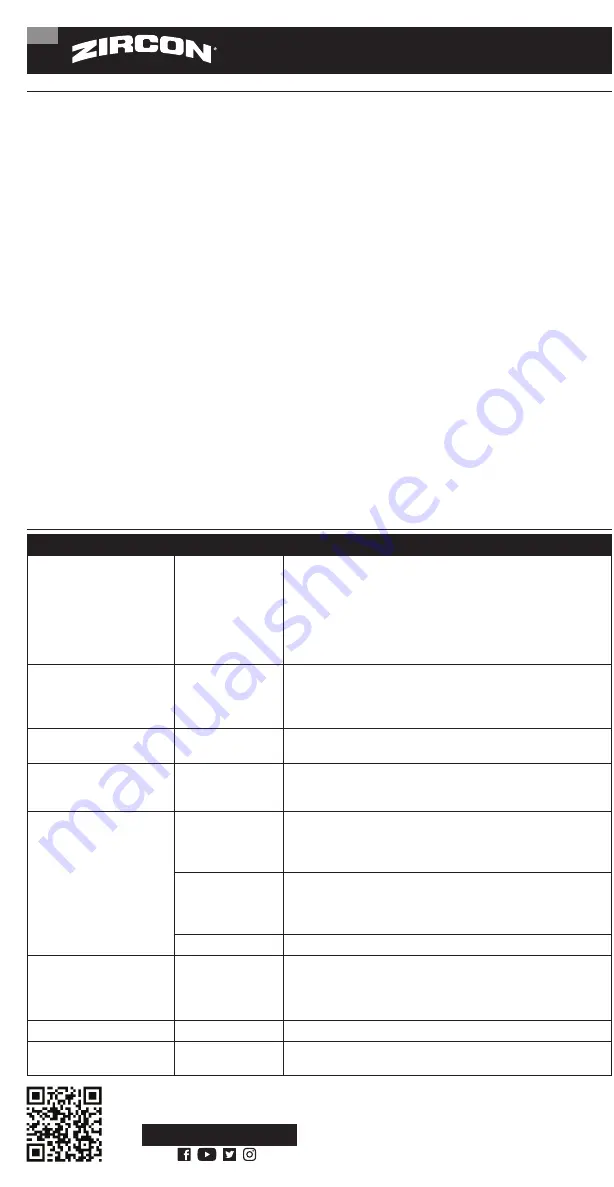

TROUBLESHOOTING & CONSTRUCTION TIPS

SITUATION

LIKELY CAUSE

SOLUTION

Scanner detects objects other

than studs in StudScan mode

or finds more objects that

look like studs than should

be there.

Electrical wiring

and metal or plastic

pipes may be near,

or touching, the back

of the wall surface.

• Scan the area in Metal Scan to determine if metal is present.

• Check for other studs equally spaced to either side at 16" or 24" (40

cm or 60 cm) and check for the same stud at spots directly above or

below the first scan area.

• Standard studs measure approximately 1½" (38 mm) between edges.

Anything smaller or larger is likely not a stud (unless near door or

window).

Difficulty detecting metal.

Metal object is too

deep or too small.

• Try calibrating in another location.

• Scan in both horizontal and vertical directions. Metal sensitivity is

increased when metal object is parallel to the sensor (located under the

Zircon

®

logo).

Metal object reading appears

wider than actual size.

Metal has a greater

density than wood.

To reduce sensitivity in Metal Mode, recalibrate scanner over either of

first two marks (see steps under REFINE METAL SCAN).

Studs are continuously

detected near windows and

doors.

Multiple studs are

in use.

Double and triple studs are sometimes used around doors and

windows. Headers are used above them. Detect outer edges so you

know where to begin.

Electrical wires suspected but

none detected.

Wires are shielded

by a metal conduit,

braided wire, or

metallic wall covering.

Use Metal Scan mode to scan for metal, wire, or metal conduit.

Wires deeper than

2" (50 mm) from the

surface might not be

detected.

If there is an outlet switch, turn it to ON position while scanning, but

turn OFF when working near the wires. Use extra caution if the area

has plywood, thick wood backing behind drywall, or walls that are

thicker than normal.

Wires may not be live. Plug a lamp into the outlet and turn it on to test whether wires are live.

LCD screen flashes

continuously when trying to

find stud.

Scanner is

experiencing

oversaturation of

exposure to metal.

Switch to Target Control

™

or StudScan modes to lessen sensitivity to

metal.

NOTE:

Scanner may not beep over studs 1" (25 mm) or deeper when

doing this.

Low Battery Indicator on.

Low battery.

Install a new 9V alkaline battery with an extended expiration date.

Low Battery Indicator flashes

and scanner does not operate. Dead battery.

Install a new 9V alkaline battery with an extended expiration date.

EN

FCC Part 15 Class B Registration Warning: This device

complies with Part 15 of FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause

harmful interference, and (2) this device must accept any

interference received, including interference that may cause

undesired operation.

LIMITED LIFETIME WARRANTY

Zircon Corporation (“Zircon”) warrants to the original purchaser (or

original user by gift) that this product will be free from defects in

materials and workmanship for its useful life (not to exceed twenty years

from date of purchase).This warranty is limited to the electronic circuitry

of the product, and specifically excludes consumable parts, including

batteries, and software, even if packaged with the product. Defects

caused by abuse, modification, handling contrary to these instructions,

other unreasonable use, or neglect are not covered under this warranty.

No liability is accepted for normal wear and tear and minor defects

which do not detract from the function of the product.

THIS LIMITED LIFETIME WARRANTY IS IN LIEU OF ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT WILL ZIRCON BE LIABLE FOR ANY SPECIAL,

INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES RESULTING

FROM POSSESSION, USE, OR MALFUNCTION OF THIS PRODUCT. NO

OTHER REPRESENTATIONS OR CLAIMS OF A SIMILAR NATURE WILL

BIND OR OBLIGATE ZIRCON.

Some states do not allow limitations on certain implied warranties and/

or the limitation on incidental or consequential damages, so the above

limitations and exclusions may not apply to you. This warranty gives you

specific legal rights, and you may also have other rights which vary from

state to state. This Limited Lifetime Warranty applies only to products

purchased within the United States of America (USA) and Canada. For

warranty applicable to products purchased in all other geographical

areas, see www.zircon.com/warranty.

Any in-warranty defective product returned to Zircon, freight prepaid,

along with dated purchase receipt and $10.00 to cover shipping and

handling, will be repaired or replaced, at Zircon’s option. If the returned

product is no longer available, Zircon may replace the product with a

similar product of similar function. This is your sole and exclusive remedy

for breach of this Limited Lifetime Warranty. To return product, call the

Zircon Customer Service number below to request an RMA number and

return product with shipment tracking to:

Zircon Corporation

Attn: Returns Department

1580 Dell Avenue

Campbell, CA 95008-6992 USA

Include your name, return address, RMA number, and package tracking

number. Allow 4–6 weeks for delivery.

If you do not agree to the terms of this Limited Lifetime Warranty, you

may not use this product and must promptly return it to the retailer,

along with a dated purchase receipt within 30 days of purchase for a

refund of the purchase price.

Customer Service: 1-800-245-9265 or 1-408-963-4550

Monday–Friday, 8:00 a.m.–5:00 p.m. PST

www.zircon.com • info@zircon.com

©2020 Zircon Corporation • P/N 71225 • Rev A 09/20

ACT, ColorTrip, DeepScan, LoLevel, MetalliWarning,

SpotLite, SuperScan,

Target Control, TC, WireWarning, and Zircon are trademarks or registered

trademarks of Zircon Corporation.

Visit www.zircon.com for the

most current instructions.

Scan QR code for more information.

Figure D

Figure E

Figure F

Figure C

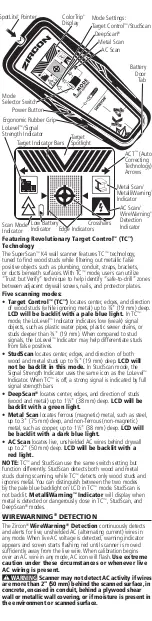

Edge Indicators

Scan Mode

Indicator

Crosshairs

LoLevel

™

/Signal

Strength Indicator

Metal Scan/

MetalliWarning

™

Indicator

Low Battery

Indicator

AC Scan/

WireWarning

®

Detection

Indicator

ACT

™

(Auto

Correcting

Technology)

Arrows

Target Indicator Bars

Target

Spotlight

SpotLite

®

Pointer

Mode Settings:

Target Control

™

/StudScan

DeepScan

®

Metal Scan

AC Scan

Battery

Door

Tab

Ergonomic Rubber Grip

Power Button

ColorTrip

®

Display

Mode

Selector Switch