TS2000 Pro Series Tripod Turnstile

User Manual

P a g e

| 10

Copyright©2021 ZKTECO CO., LTD. All rights reserved.

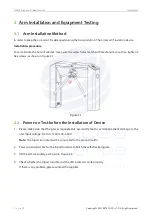

Figure 3-3

Installation

3.3

1. Drill holes.

Drill holes based on the locations of holes as shown in Figure 3-3.

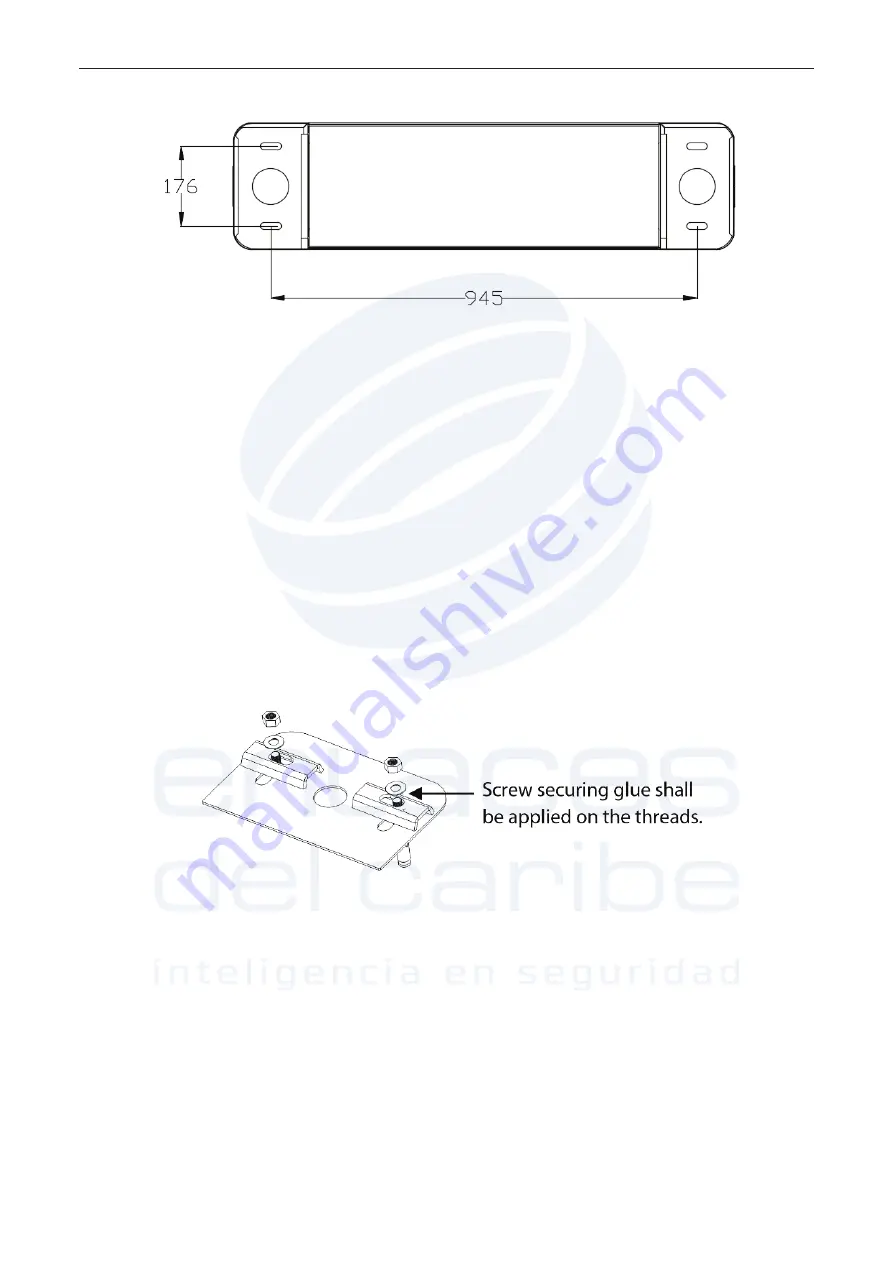

2. Fix the mounting plate to its original position.

Placing the mounting plate properly and apply screw securing glue on the surface and the threads of

the expansion bolts, install four expansion bolts to secure the mounting plate, and use a horizontal

ruler to test the levelness of the mounting plate. If the mounting plate is not level, adjust it by the

gaskets provided. Note that all the four expansion bolts must be installed properly, as shown in Figure

3-4.

Figure 3-4

3. Put the turnstile on the mounting plate and tighten the screws. Apply screw securing glue before

using and putting gaskets on the screws to adjust the direction of the turnstile. If the tripod turnstile is

not level, you can place gaskets to adjust, as shown in Figure 3-5.