Zlin Aviation

Section 1

Maintenance Manual Aircraft Maintenance Manual

Issued: 01/02/2006

QAP-AMM-Rev02

Date of latest Revision: 23/01/2013

Page Number: 1-16

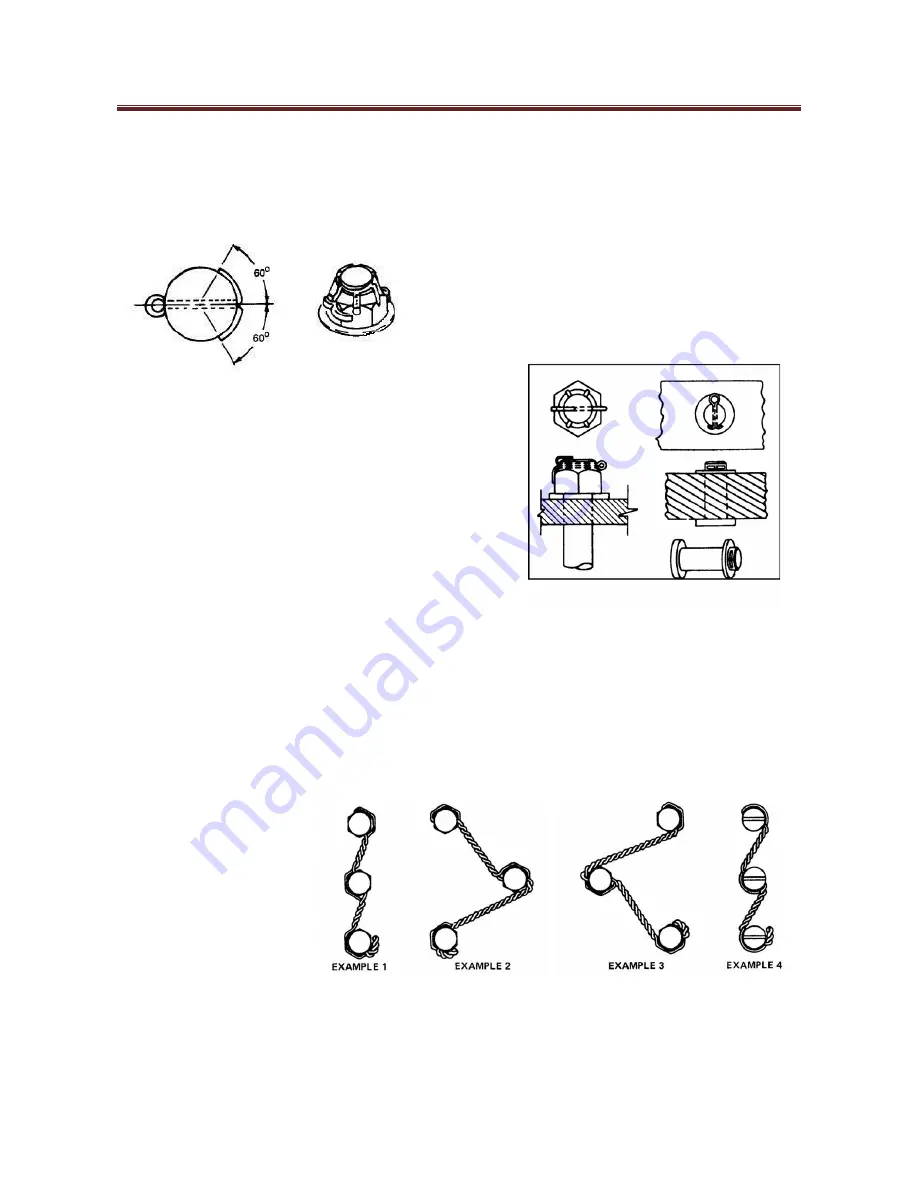

Cotter Pins

Securing by cotter pin is used for bolts subject to rotation. They are used because they can be

removed and reinstalled quickly. The diameter of the cotter pin should be the largest size that will

fit the slot in the castle nut or the hole in the bolt. To prevent injury the ends of the cotter pin should

be bent over the nut and firmly flat against each face of the nut then rolled and tucked.

Cotter pin removal is very easy: by means of a flat

screwdriver straighten up the

bent ends of the cotter pin and take the cotter pin out of

the hole with small pliers.

When securing castle nuts, always use new cotter pins.

Shift the new cotter pin into the hole in the bolt and bend

the cotter pin ends as shown in the figure.

Safety Wire

Procedure of bolt joint securing is by stainless steel wire having diameter of 0.032”.

The installation of safety wire is not intended to retain bolt or nut torque. It is installed to prevent

disengagement of screws, nuts, bolts, and other parts for added safety. Do not confuse aluminum

wire with stainless steel wire. Wire should only be stainless steel, do not use common wire or

ferrous metal which can rust or be attracted by magnetic portions of the aircraft.

Drilled bolts or screws do not need to be safety wired if they are installed with self-locking nuts.

Safety wire must be installed in a manner that will prevent the tendency of the part to loosen or

rotate. Safety wire ends are a safety hazard unless they are bent under and inward toward the part to

avoid sharp or projecting

ends. Safety wire must not

be nicked, kinked, or

mutilated. When cutting

off the end of the twisted

wire, leave at least four to

six completer turns (1/2”

to 5/8”) of wound wire to

complete a loop.

Examples of correct direction for drilled bolt safety wire