Zlin Aviation

Section 2

Maintenance Manual Line Maintenance, Repairs and Alterations

Issued: 01/02/2006

QAP-AMM-Rev02

Date of latest Revision: 23/01/2013

Page Number: 2-7

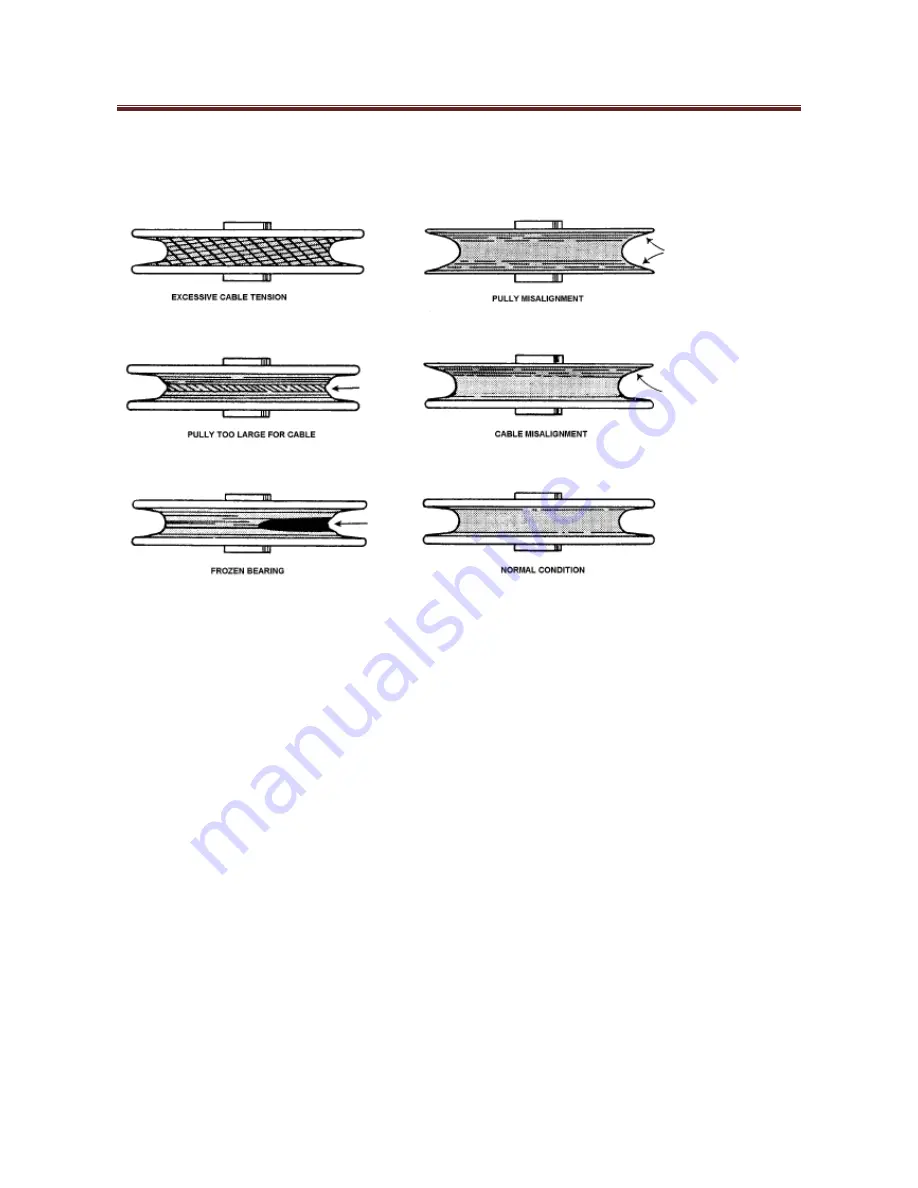

Various cable system malfunctions

may be detected by analyzing pulley conditions.

These include such discrepancies as too much tension, misalignment, pulley bearing

problems, and size mismatches between cables and pulleys. Examples of these condition are

shown in the figure.

Inspect fair-leads

for wear, breakage, alignment, cleanliness, and security. Examine cable routing

at fair-leads to ensure that defection angles are no greater than 3° maximum. Determine that all

guides and anti-abrasion strips are secure and in good condition.

CORROSION AND RUST PREVENTION.

To ensure a satisfactory service life for aircraft

control cables, use a cable lubricant to reduce internal friction and prevent corrosion.

CABLE MAINTENANCE.

Frequent inspections and preservation measures such as rust-

prevention treatments for bare carbon steel cable areas, will help to extend cable service life. Where

cables pass through fair-leads, pressure seals, or over pulleys, remove accumulated heavy coatings

of corrosion-prevention compound. Provide corrosion protection for these cable sections by

lubricating with a light coat of grease or general purpose, low-temperature oil.