Pelletherm V.4 LT

31

6.

INITIATION OF THE SYSTEM TO OPERATION.

The system, consisting of a hot water pellet boiler from series “Pelletherm V.4

LT” and an automated pellet burner from series “GP xx sc”, must be initiated

to operation only by specialized company authorized for such activities.

6.1.

MAIN REQUIREMENTS ABOUT THE USED FUEL TYPE.

When initiating the system to operation, consisting of a hot water boiler from series

“Pelletherm V.4 LT” and a pellet burner from series “GP xx sc”, the following fuel

requirements must be observed:

To achieve complete fuel burning it is necessary to use only dried fuel, complying

with the requirements for reliable operation that are presented in the pellet burner’s

manual book. The manufacturing company recommends to store the fuel in dry and

ventilated premises;

It is forbidden to store the fuel next to the heating system (boiler and burner) or at

distance less than 400 mm from it;

The optimal recommended distance by the manufacture company is at least 1000

mm. Preferably store the fuel in a neighbor room;

When installing the system, consisting of a hot water pellet boiler from series

“Pelletherm V.4 LT” and an automated pellet burner from series “GP xx sc” and when

storing the fuel all fire safety requirements must be observed. It is recommended to

position a fire-extinguisher at an easy access and safe place near the boiler.

6.2.

INITIATION OF THE SYSTEM, A HOT WATER BOILER FROM SERIES

“PELLETHERM V.4 LT” AND A PELLET BURNER FROM SERIES “GP XX SC”,

TO OPERATION.

When initiating the system to operation, consisting of a hot water pellet boiler from series

“Pelletherm V.4 LT” and a pellet burner from series “GP xx sc”, the following main

requirements must be observed:

Maintenance of the hot water pellet boiler must be performed in accordance to the

manual for maintenance and operation;

Any interference to the operation of the system that might lead to risk for the health of

the servicing personal or to other indirectly linked people is strictly forbidden;

During operation the system has to be periodically checked by the user/servicing

staff;

The user must not perform any repairs over the system modules. If a failure or a

problem occurs during operation then the users must ask for technical assistance by

a servicing company;

It is forbidden to increase the burner’s, respectively the boiler’s heating output above

the nominal;

The ash remaining from the burning process must be gathered in proper fire-proof

container and after cooling to ambient temperature it has to be dumped to proper for

the purpose places.

During the operation of the hot water pellet boiler "Pelletherm V.4 LT" do not

open the door of the burning chamber.

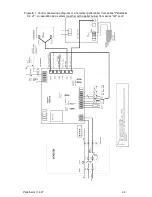

6.2.1. INTERFACE PANEL FOR CONNECTION AND MANAGEMENT OF THE PELLET

BURNER’S FROM SERIES “GP XX SC” CONTROL PANEL.

The system, consisting of a hot water pellet boiler from series “Pelletherm V.4 LT” and a

pellet burner from series “GP xx sc”, is managed by control block, positioned in the burner’s

main module. It has display and keyboard, through which the system operation parameters

can be changed. More information is presented in the pellet burner from series “GP xx sc”

manual book. The interface panel controls and their functions are:

Summary of Contents for GP ** sc

Page 46: ...Pelletherm V 4 LT 46...

Page 48: ...Pelletherm V 4 LT 48...