p. 13/69

•

Emergency cooling coil is utilized for alarm cooling of circulating water

in the boiler’s heat exchanger in case that the water temperature has

reached high levels. This coil has connecting thread of size G½”;

•

The flue exit duct (the external diameter is described in table 2.2) is

positioned in the back upper of the boiler and extracts the flue gases out of

the convective section of the boiler;

•

The heat exchanger is thermally insulated with mineral wool, which

allows lower heat loses to the surrounding atmosphere;

•

The doors of the fuel hopper and the combustion chamber are fabricated

from cast iron, which allow high thermal resistance and air tightness of

the boiler;

•

The outer covers of the boiler are manufactured from steel plates and are

finally color painted;

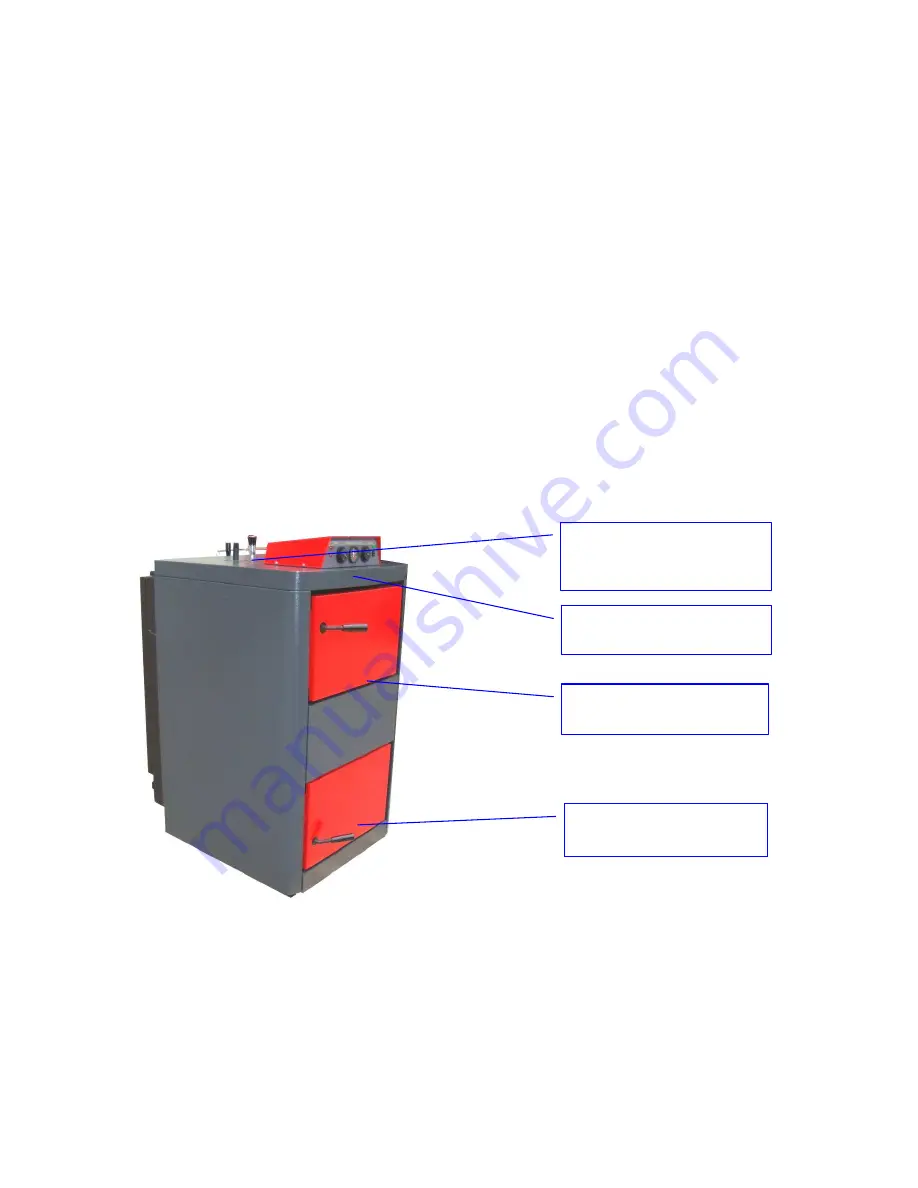

The next figures show the dimensions and the design of the wood gasification

hot water boiler of series “Pyrotherm”.

Figure 3.1 Side view of wood gasification hot water boiler of series

“Pyrotherm” – the main elements of the boiler are described;

Control board of the boiler

Fuel hopper door

Combustion chamber door

Thermovalve for

controlling the air flow rate