ZMC308BE Motion Controller Hardware Manual V1.5

connecting to a computer.

⚫

Please be sure to connect the common terminal of each communication node to

prevent the communication chip from burning out.

⚫

Please use twisted-pair shielded cables, especially in harsh environments, and make

sure the shielding layer is fully grounded.

3.3.2.

Basic Usage

(1)

Please follow the above wiring instructions for correct wiring.

(2)

After power on, please use ETHERNET or RS232 (default parameter, it can be

connected directly) to connect to ZDevelop.

(3)

Please use the "ADDRESS" and "SETCOM" commands to set and view the protocol

station number and configuration parameters, see "ZBasic Programming Manual" for

details.

(4)

Correctly set the relevant parameters of the third-party equipment according to their

respective instructions to match the parameters of each node.

(5)

When all is configured, it can start to do communicating.

(6)

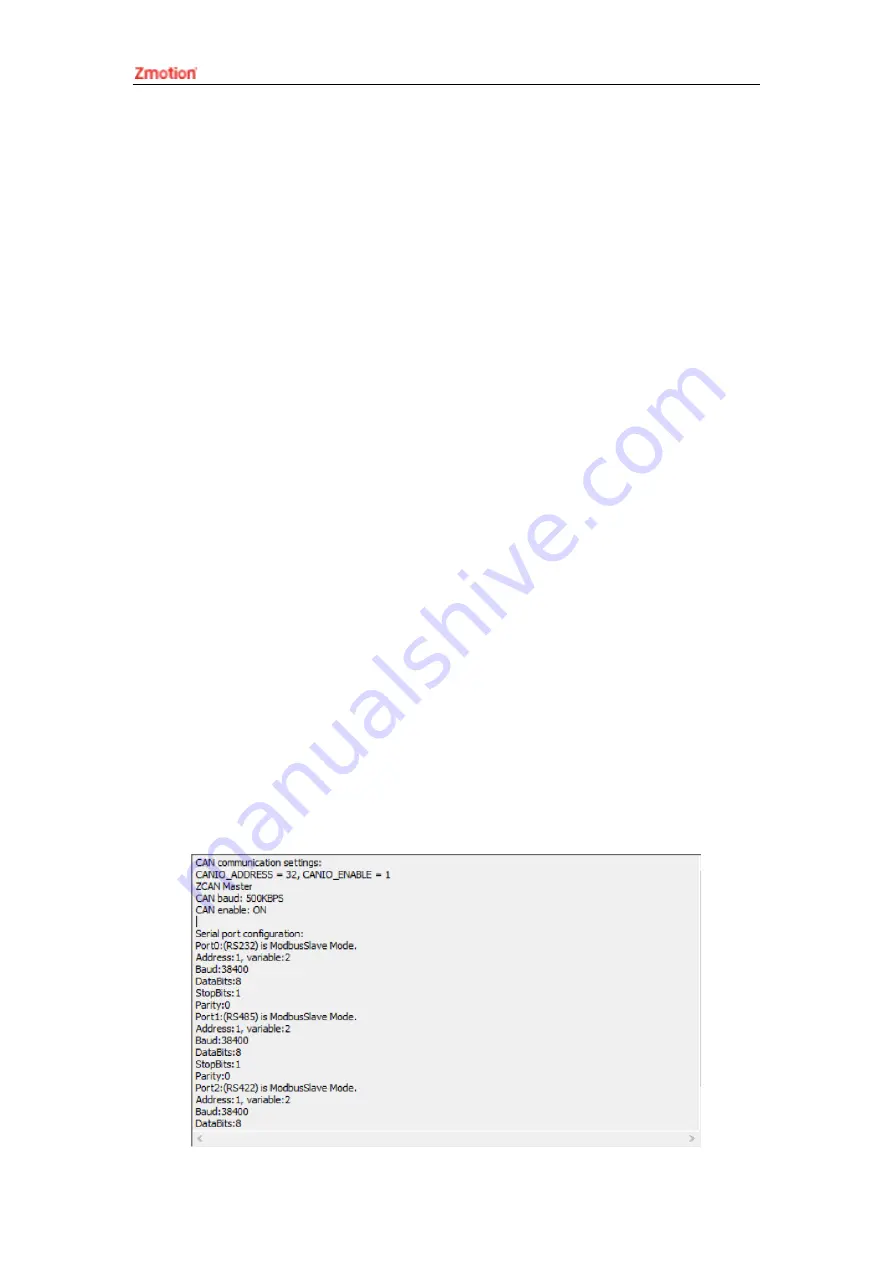

Communication data of RS232 can be directly viewed through “ZDevelop / Controller

/ State the Controller / CommunicationInfo”.

Summary of Contents for ZMC308BE

Page 1: ......